2012 No-Dig Show Heads to Nashville

January 19, 2012

Nashville is home to the historic Grand Ole Opry and all things country music, all the way down to the 10-gallon hats and cowboy boots. But for five days in March, the Music City welcomes back the trenchless technology community for its annual conference and exhibition.

Nashville is home to the historic Grand Ole Opry and all things country music, all the way down to the 10-gallon hats and cowboy boots. But for five days in March, the Music City welcomes back the trenchless technology community for its annual conference and exhibition.Trenchless professionals from around the globe will gather in the Tennessee capitol city March 11-15 for the 21st annual No-Dig Conference and Exhibition. The all-trenchless event takes place at the Gaylord Opryland Hotel and Convention Center.

Sponsored by the North American Society of Trenchless Technology (NASTT), this annual event draws trenchless professionals from around the world to the largest conference and tradeshow in North America dedicated solely to the promotion of trenchless technology. Through exhibits, educational seminars and fun networking events, the No-Dig Show is a must-attend event for the trenchless professional. Of particular note in 2012 is the inaugural NASTT Hall of Fame class, honoring the industry-changing accomplishments of deserving NASTT members.

2011 was a good year for the trenchless industry, and this year’s conference hopes to capitalize on that momentum with a strong No-Dig Show. In 2012, more than 140 exhibitors will fill the 70,000-sq ft exhibit hall, displaying the latest in trenchless equipment and technology and be on hand to answer attendees’ questions.

Along with the jam-packed exhibit hall, the No-Dig technical paper program is also an important part of the show’s success and stature, which has become the heart and soul of the conference. 2012 brings 155 peer-reviewed technical papers to be presented, focusing on a diverse range of trenchless topics, including horizontal directional drilling (HDD), cured-in-place pipe (CIPP), microtunneling, inspection, case histories, asset management, pipe jacking and ramming, water and sewer rehabilitation, project planning, inspection and trenchless research.

Attendees can choose among which peer-reviewed paper presentations they want to see. The papers are evaluated based on relevance, usefulness and non-commercialism. The No-Dig papers are presented in a six-track schedule and are grouped mostly by subject matter so attendees can choose to attend five paper presentations at any given time.

Pre- and post-conference seminars are also on the schedule for attendees at an additional cost. On Sunday, March 11, NASTT’s Trenchless Technology Short Course-New Construction and Rehabilitation will be held. The course is ideally suited for both newcomers to the industry and for anyone who is interested in seeking a refresher course on trenchless technology methods. The course covers new installation and rehabilitation methods.

On March 14-17, several informative courses are slated, presented by NASTT and NASSCO. From NASTT: Cured-in-Place Pipe Good Practices Course; Laterals Rehabilitation & Replacement Good Practices Course; HDD Consortium Horizontal Directional Drilling Good Practices Guidelines Course; Pipe Bursting Good Practices Course; and New Installation Methods Good Practices. From NASSCO: PACP Trainer Recertification; PACP Trainer Upgrade; Pipeline Assessment and Certification Program; and Lateral and Manhole Assessment Certification Program.

Although the No-Dig show is the conduit to promote and advance the trenchless marketplace through education and exhibits, there’s also the social aspect of the conference that fosters networking opportunities for attendees, as well as just some good times.

The conference gets under way with its annual Kick-off Breakfast on Monday, March 12. During this event, the formal presentation of the 2012 Trenchless Technology Person of the Year will be made, as well as recognition of the winners of the 2011 Trenchless Technology Projects of the Year for Rehabilitation and New Installation. Also, the 2011 Outstanding Papers in Rehabilitation and New Installation Awards will be announced. Entertainment for this event will be comedian Tim Gabrielson, who blends comedy, magic and inspirational principles in his performances.

Also on March 12, NASTT will hold its 11th annual Educational Fund Auction & Reception. This annual event is the perfect opportunity for attendees to mingle and relax, as well as bid on items for an excellent cause — the Educational Fund, which supports student chapters, target research, training modules and other student activities. Past items for bid have included trips, electronics, Major League Baseball tickets, NASCAR events, as well as jewelry and trenchless products. Since 2001, this auction has raised more than $433,000, including 2011’s record-setting total of $75,000. Come in your best western costume and compete for best costume.

Also on March 12, NASTT will hold its 11th annual Educational Fund Auction & Reception. This annual event is the perfect opportunity for attendees to mingle and relax, as well as bid on items for an excellent cause — the Educational Fund, which supports student chapters, target research, training modules and other student activities. Past items for bid have included trips, electronics, Major League Baseball tickets, NASCAR events, as well as jewelry and trenchless products. Since 2001, this auction has raised more than $433,000, including 2011’s record-setting total of $75,000. Come in your best western costume and compete for best costume. On Tuesday, March 13, NASTT will host its annual Gala Awards Dinner. During this popular event, the trenchless community gathers for a night of fun, food and dancing to live entertainment. Nashville-based band Sharie Bardo Explosion will also entertain the crowd. Also, the inaugural inductees into the NASTT Hall of Fame will be enshrined: the late Gary Vermeer, Vermeer Corp., Frank Canon, Baroid Industrial Drilling Products, and Bernie Krzys, president and publisher of Trenchless Technology magazine.

To close out the 2012 No-Dig event is the annual Closing Luncheon on Wednesday, March 14. Here, attendees can enjoy lunch, entertainment and say good-bye to their fellow trenchless professionals before heading home. The location for the 2015 No-Dig Show will be announced, as well.

For more information about the 2012 No-Dig Show, visit www.nodigshow.com or contact Benjamin Media, which handles the show’s management, at 330-467-7588.

Sharon M. Bueno is managing editor of Trenchless Technology.

Adeunis NA

Adeunis NA is a subsidiary of Adeunis RF, dedicated to the sale of VOKKERO products in the U.S. and Canadian markets. Vokkero is an all-in-one, hands-free wireless communication system that enables drilling and excavation teams to communicate in a private and portable network, so work may be completed more safely, efficiently and accurately, even in the most challenging environments. Additional benefits of the Vokkero system:

Adeunis NA is a subsidiary of Adeunis RF, dedicated to the sale of VOKKERO products in the U.S. and Canadian markets. Vokkero is an all-in-one, hands-free wireless communication system that enables drilling and excavation teams to communicate in a private and portable network, so work may be completed more safely, efficiently and accurately, even in the most challenging environments. Additional benefits of the Vokkero system:- Full-duplex communication system which is set up in minutes and requires no fixed base-station or licenses.

- Totally hands-free, allowing work to be completed without the distractions typically experienced with other communication systems.

- Extremely clear communication thanks to the high-performance Vokkero noise filter paired with noise blocking headsets, ensuring optimal sound quality and eliminating miscommunications even in noisy environments.

- Reduced risk and increased efficiency.

- The new Evolution Three model offers an expanded range of options for more complex communication needs.

Visit Adeunis NA at Booth #1202

Akkerman

The original 5000 Series Pump Unit — the flagship product for Akkerman and the heart of its all-in-one 5000 Series pipe jacking system — has been a powerful companion on a vast number of pipe jacking jobs. The completely revamped and enhanced 5000 Series II Pump Unit features streamlined operation and functionality, an incorporated dual-feed pump to power all TBM sizes, a raised operator’s station with ergonomic controls, many safety provisions and improved maintenance accessibility. Also new to this equipment line is the bi-directional, bearing based drive TBM 720 Series II. Designed to excavate a wider range of geology than its past TBMs with a change in cutter head configuration, the TBM 720 Series II is capable of cutting rock. For almost four decades, Akkerman has manufactured distinctive microtunneling, pipe jacking, tunneling and guided boring equipment. Visit the Akkerman booth for information about the Series II products and other quality Akkerman equipment. Booth #701

The original 5000 Series Pump Unit — the flagship product for Akkerman and the heart of its all-in-one 5000 Series pipe jacking system — has been a powerful companion on a vast number of pipe jacking jobs. The completely revamped and enhanced 5000 Series II Pump Unit features streamlined operation and functionality, an incorporated dual-feed pump to power all TBM sizes, a raised operator’s station with ergonomic controls, many safety provisions and improved maintenance accessibility. Also new to this equipment line is the bi-directional, bearing based drive TBM 720 Series II. Designed to excavate a wider range of geology than its past TBMs with a change in cutter head configuration, the TBM 720 Series II is capable of cutting rock. For almost four decades, Akkerman has manufactured distinctive microtunneling, pipe jacking, tunneling and guided boring equipment. Visit the Akkerman booth for information about the Series II products and other quality Akkerman equipment. Booth #701American Augers

The latest concept from American Augers is the P-600 Mud Pump. It features a Kerr tri-plex 600-gpm pump with a rated capacity of 600 U.S. gals. The big valves on this new pump allow contractors to use a higher viscosity mud without lowering the flow rate. This, in turn, means a smaller pump with a smaller engine can be utilized thus increasing fuel savings. The Cat C-15 engine is Tier 3 or Tier 4i interchangeable depending on country of purchase. The P600 is a remarkable drilling accessory that is now available with an optional Quiet Pak for increased sound control and is compatible with any drill brand. As always, American Augers machines are supported through a dedicated parts and technical service department. Booth #1212

The latest concept from American Augers is the P-600 Mud Pump. It features a Kerr tri-plex 600-gpm pump with a rated capacity of 600 U.S. gals. The big valves on this new pump allow contractors to use a higher viscosity mud without lowering the flow rate. This, in turn, means a smaller pump with a smaller engine can be utilized thus increasing fuel savings. The Cat C-15 engine is Tier 3 or Tier 4i interchangeable depending on country of purchase. The P600 is a remarkable drilling accessory that is now available with an optional Quiet Pak for increased sound control and is compatible with any drill brand. As always, American Augers machines are supported through a dedicated parts and technical service department. Booth #1212AOC

AOC expands the industry’s best selection of cured-in-place pipe resins with new Vipel L085 epoxy novolac vinyl ester for more demanding, corrosion-resistant applications. The resin’s epoxy novolac chemistry provides superior resistance to acids, bases and many organic solvents. L085 also imparts resistant properties in higher temperature environments, whether the media is liquid or gaseous. The new product underscores AOC’s commitment to leadership in resin technology, consistency and technical support. Visit the AOC booth to learn more about AOC products, including ultralow volatile organic compound (VOC) resins for emissions and odor-sensitive projects. Case histories at the booth show how AOC resins are designed to meet specific process and performance needs. Join the growing number of engineers, contractors and owners who find that AOC knows technology, lives quality and delivers service better than any other resin supplier. Booth #1001

AOC expands the industry’s best selection of cured-in-place pipe resins with new Vipel L085 epoxy novolac vinyl ester for more demanding, corrosion-resistant applications. The resin’s epoxy novolac chemistry provides superior resistance to acids, bases and many organic solvents. L085 also imparts resistant properties in higher temperature environments, whether the media is liquid or gaseous. The new product underscores AOC’s commitment to leadership in resin technology, consistency and technical support. Visit the AOC booth to learn more about AOC products, including ultralow volatile organic compound (VOC) resins for emissions and odor-sensitive projects. Case histories at the booth show how AOC resins are designed to meet specific process and performance needs. Join the growing number of engineers, contractors and owners who find that AOC knows technology, lives quality and delivers service better than any other resin supplier. Booth #1001AP/M Permaform

Since 1976, AP/M has helped cities, engineers and contractors select the best tool for each different manhole problem with its PERMACAST system of structural cement liners, coatings, structural polymers, cured-in-place liners, chimney seals, channel liners and more. In 1996, it introduced its ConmicShield additive for long-term, internal corrosion protection of concrete. Since it is added during mixing, it is not a surface treatment that can wear off or delaminate. Now, CentriPipe is available for trenchless, structural lining of large diameter culverts and sanitary pipe. Booth #302

Since 1976, AP/M has helped cities, engineers and contractors select the best tool for each different manhole problem with its PERMACAST system of structural cement liners, coatings, structural polymers, cured-in-place liners, chimney seals, channel liners and more. In 1996, it introduced its ConmicShield additive for long-term, internal corrosion protection of concrete. Since it is added during mixing, it is not a surface treatment that can wear off or delaminate. Now, CentriPipe is available for trenchless, structural lining of large diameter culverts and sanitary pipe. Booth #302Aries Industries

The Pathfinder XL from Aries Industries is a six-wheel steerable tractor designed to fit in relined 8-in. and larger pipe with a remote-operated camera lift. This versatile tractor is engineered for unmatched pulling power and inspection capability. The standard tires range from 3-3/8 in. for relined 8-in. pipe up to optional 10-in. tires with bolt-on gear-reduction side plates for 36-in. and larger pipe. An optional tread-track drive kit is also available. With 9 in. of camera lift, the operator can center the camera in the pipe or raise the camera above the water line. Additional features include a tip-up connector with integral rear viewing camera and LED lights, sealed and pressurized electronics cavities and on-screen diagnostics. The XL has a built-in 512 Hz sonde beacon for locating, and the optional auxiliary light easily lights up the darkest large diameter pipe. Booth #208

The Pathfinder XL from Aries Industries is a six-wheel steerable tractor designed to fit in relined 8-in. and larger pipe with a remote-operated camera lift. This versatile tractor is engineered for unmatched pulling power and inspection capability. The standard tires range from 3-3/8 in. for relined 8-in. pipe up to optional 10-in. tires with bolt-on gear-reduction side plates for 36-in. and larger pipe. An optional tread-track drive kit is also available. With 9 in. of camera lift, the operator can center the camera in the pipe or raise the camera above the water line. Additional features include a tip-up connector with integral rear viewing camera and LED lights, sealed and pressurized electronics cavities and on-screen diagnostics. The XL has a built-in 512 Hz sonde beacon for locating, and the optional auxiliary light easily lights up the darkest large diameter pipe. Booth #208Avanti International

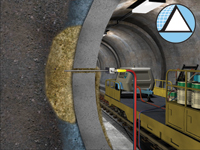

Avanti’s AV-100 Chemical Grout is an ultra-low viscosity chemically-activated gel and the U.S. Department of Energy’s product of choice for long-term control of groundwater and infiltration. Avanti’s AV-100 has the same viscosity as water, which allows it to quickly permeate the substrate and cure to form a matrix with the soil and porous rock. The image illustrates how the product is used to create an effective, long-lasting water barrier and superb soil stabilizer. AV-100 helps contractors stop infiltration without chasing the water from crack to crack by forming an impermeable grout curtain outside underground structures (i.e. subways, vaults, wet wells, lift stations, manholes, parking garages, etc.). Avanti’s AV-100 has been successfully used for decades via probe grouting, remote packer grouting, curtain grouting and tube-a-manchette grouting for pre-excavation groundwater control, hazardous waste encapsulation, prevention of structural movement due to groundwater, as well as sealing entire sewer and underground transit systems. Booth #1201

Avanti’s AV-100 Chemical Grout is an ultra-low viscosity chemically-activated gel and the U.S. Department of Energy’s product of choice for long-term control of groundwater and infiltration. Avanti’s AV-100 has the same viscosity as water, which allows it to quickly permeate the substrate and cure to form a matrix with the soil and porous rock. The image illustrates how the product is used to create an effective, long-lasting water barrier and superb soil stabilizer. AV-100 helps contractors stop infiltration without chasing the water from crack to crack by forming an impermeable grout curtain outside underground structures (i.e. subways, vaults, wet wells, lift stations, manholes, parking garages, etc.). Avanti’s AV-100 has been successfully used for decades via probe grouting, remote packer grouting, curtain grouting and tube-a-manchette grouting for pre-excavation groundwater control, hazardous waste encapsulation, prevention of structural movement due to groundwater, as well as sealing entire sewer and underground transit systems. Booth #1201Can Clay Corp.

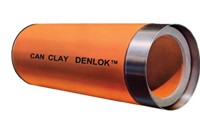

Denlok jacking pipes offer unsurpassed proven life in sanitary sewer installations. Denlok pipes have resulted in successful projects on six continents. Ceramic pipe is combined with 29-psi joints of 316 stainless steel, which results in water-tight performance to depths of over 70 ft. Denlok’s high-compression strengths of greater than 10,875 psi results in high jacking strengths of up to 2,800 tons. World-record lengths of microtunneling drives have been performed when using Denlok pipes. Denlok is offered in sizes from 4- to 48-in. diameters and lengths to 10 ft. Choose Denlok for unsurpassed installation success and sustainable low cost ownership. Manufactured under a certified ISO 9001:2008 quality control system and supplied with factory manufactured cushion rings. Booth #516

Denlok jacking pipes offer unsurpassed proven life in sanitary sewer installations. Denlok pipes have resulted in successful projects on six continents. Ceramic pipe is combined with 29-psi joints of 316 stainless steel, which results in water-tight performance to depths of over 70 ft. Denlok’s high-compression strengths of greater than 10,875 psi results in high jacking strengths of up to 2,800 tons. World-record lengths of microtunneling drives have been performed when using Denlok pipes. Denlok is offered in sizes from 4- to 48-in. diameters and lengths to 10 ft. Choose Denlok for unsurpassed installation success and sustainable low cost ownership. Manufactured under a certified ISO 9001:2008 quality control system and supplied with factory manufactured cushion rings. Booth #516CertainTeed

CertainTeed will be showcasing its Certa-Lok C900/RJ PVC Pipe at the show. Certa-Lok is the first non-metallic water and sewer piping system designed for use in directional drilling and other restrained joint applications. It requires no special heat-fusion equipment, saving contractors a significant amount of time and money. Its joints are assembled as the pullback continues, so streets remain open and clear. And compared to alternate thermoplastic materials, higher-strength PVC requires a much thinner wall in order to achieve the same pressure rating. Booth #912

CUES

CUES offers a full line of portable and mounted grout rehabilitation systems. Truck- and trailer-mounted grout rehabilitation systems are available for mainline, manhole and lateral joint sealing and can be equipped with the latest CCTV equipment and decision support software for television inspection with documented condition assessment. All systems can be configured to run urethane, acrylimide and acrylate grouts. Systems can be mounted in a dry freight box for export. Grout packers are available for mainline and lateral sealing. Booth #522

CUES offers a full line of portable and mounted grout rehabilitation systems. Truck- and trailer-mounted grout rehabilitation systems are available for mainline, manhole and lateral joint sealing and can be equipped with the latest CCTV equipment and decision support software for television inspection with documented condition assessment. All systems can be configured to run urethane, acrylimide and acrylate grouts. Systems can be mounted in a dry freight box for export. Grout packers are available for mainline and lateral sealing. Booth #522Derrick Equipment

Derrick Equipment’s DE-7200 VFD (Variable Frequency Drive) Centrifuge provides a new concept in centrifuge operation and control. Automatic load sensing and feed pump control enables automated performance up to 500-gpm, volumetric capacity and 12 to 14 T/Hr of fine solids discharge. High-capacity fine solids removal enables contractors to more efficiently maintain desired drilling fluid properties with reduced mud disposal costs and increased production. The inverter duty drive system has a 150-hp bowl drive and 60-hp conveyor drive powered by AC drives. Motor drives and peripheral devices are controlled by an environmentally hardened PLC that offers operating flexibility and data storage. Booth #1110

Derrick Equipment’s DE-7200 VFD (Variable Frequency Drive) Centrifuge provides a new concept in centrifuge operation and control. Automatic load sensing and feed pump control enables automated performance up to 500-gpm, volumetric capacity and 12 to 14 T/Hr of fine solids discharge. High-capacity fine solids removal enables contractors to more efficiently maintain desired drilling fluid properties with reduced mud disposal costs and increased production. The inverter duty drive system has a 150-hp bowl drive and 60-hp conveyor drive powered by AC drives. Motor drives and peripheral devices are controlled by an environmentally hardened PLC that offers operating flexibility and data storage. Booth #1110Digital Control Inc.

The DigiTrak F5 Directional Drilling Locating System represents the most versatile locating system available to HDD contractors today. Evolving from 20 years of HDD locating experience, the F5 incorporates and improves upon DCI’s Eclipse locating technology, which has become the industry standard. The F5 system also incorporates DCI’s patented 3D antenna technology, target-in-the-box locating, and intuitive picture-driven menus, with new colorful and easy-to-use graphics. A four-way toggle switch below the display makes operation simple. The increased versatility of the F5system includes five unique frequency options, providing the capability to overcome most interference problems and to locate to depths of 85 ft. Booth #925

The DigiTrak F5 Directional Drilling Locating System represents the most versatile locating system available to HDD contractors today. Evolving from 20 years of HDD locating experience, the F5 incorporates and improves upon DCI’s Eclipse locating technology, which has become the industry standard. The F5 system also incorporates DCI’s patented 3D antenna technology, target-in-the-box locating, and intuitive picture-driven menus, with new colorful and easy-to-use graphics. A four-way toggle switch below the display makes operation simple. The increased versatility of the F5system includes five unique frequency options, providing the capability to overcome most interference problems and to locate to depths of 85 ft. Booth #925Ditch Witch

The Ditch Witch OnGrade system utilizes laser technology, advanced Ditch Witch electronics, and the industry’s most innovative downhole tools to help you drill accurate grade bores every time. The advantage of the patented OnGrade method over other grade-drilling methods is a laser-guided reference point from the entry to the exit pits. From this fixed reference, all depth measurements are taken. For the drill operator, it’s a matter of maintaining a constant distance between the drill string and the laser line and making steering corrections as necessary all the way to the exit pit. Booth #507

The Ditch Witch OnGrade system utilizes laser technology, advanced Ditch Witch electronics, and the industry’s most innovative downhole tools to help you drill accurate grade bores every time. The advantage of the patented OnGrade method over other grade-drilling methods is a laser-guided reference point from the entry to the exit pits. From this fixed reference, all depth measurements are taken. For the drill operator, it’s a matter of maintaining a constant distance between the drill string and the laser line and making steering corrections as necessary all the way to the exit pit. Booth #507Duke’s Root Control

Duke’s Root Control Inc. is a full-service root control company dedicated to keeping sewer systems free of tree root growth. Through professional application of Duke’s proprietary herbicide, Razorooter II, over 2,000 U.S. municipalities have benefited from extended pipe life, reduced SSO occurrences and maximized asset value. Duke’s has successfully treated over 140 million ft of sewer line and continues to deliver results to municipalities through: Asset Management and CMOM Solutions, EPA-registered products and a two- to three-year guarantee. A sister company to Duke’s Root Control, Sewer Sciences, is a leading producer of innovative, effective solutions for the sewer root control industry. Using cutting-edge technology and research methodology, Sewer Sciences has developed EPA-registered products that effectively control root growth without compromising wastewater treatment facilities, the environment and local communities. Sewer Sciences has also consulted with the U.S. EPA to create training manuals for instructing and certifying root-control applicators in proper application techniques. As a steward of the sewer root control industry, Sewer Sciences recently launched www.rootonctrolfacts.com. Booth #614

Duke’s Root Control Inc. is a full-service root control company dedicated to keeping sewer systems free of tree root growth. Through professional application of Duke’s proprietary herbicide, Razorooter II, over 2,000 U.S. municipalities have benefited from extended pipe life, reduced SSO occurrences and maximized asset value. Duke’s has successfully treated over 140 million ft of sewer line and continues to deliver results to municipalities through: Asset Management and CMOM Solutions, EPA-registered products and a two- to three-year guarantee. A sister company to Duke’s Root Control, Sewer Sciences, is a leading producer of innovative, effective solutions for the sewer root control industry. Using cutting-edge technology and research methodology, Sewer Sciences has developed EPA-registered products that effectively control root growth without compromising wastewater treatment facilities, the environment and local communities. Sewer Sciences has also consulted with the U.S. EPA to create training manuals for instructing and certifying root-control applicators in proper application techniques. As a steward of the sewer root control industry, Sewer Sciences recently launched www.rootonctrolfacts.com. Booth #614Echologics Engineering Inc., a Division of Mueller Co.

Echologics has enhanced its acoustic leak listening device, LeakTuner, to further increase the precision in which users can locate leaks in water distribution pipelines without breaking ground or disrupting service. The enhancement includes a wider range of frequency settings that municipal workers can choose from in order to further reduce electronic white noise, as well as ambient background noise when testing for leaks. Using LeakTuner, workers listen for leaks through headsets that connect to acoustical sensors, which are directly attached to pipes, hydrants, valves or fittings. By reducing ambient and electronic noise, LeakTuner improves users’ ability to clearly hear leak sounds with reduced interference from background noise, so even the quietest leaks can be heard more easily on pipes of nearly all sizes and materials, including asbestos cement, copper, galvanized steel, polyvinyl chloride (PVC), concrete and ductile iron and cast iron. Booth #515

Echologics has enhanced its acoustic leak listening device, LeakTuner, to further increase the precision in which users can locate leaks in water distribution pipelines without breaking ground or disrupting service. The enhancement includes a wider range of frequency settings that municipal workers can choose from in order to further reduce electronic white noise, as well as ambient background noise when testing for leaks. Using LeakTuner, workers listen for leaks through headsets that connect to acoustical sensors, which are directly attached to pipes, hydrants, valves or fittings. By reducing ambient and electronic noise, LeakTuner improves users’ ability to clearly hear leak sounds with reduced interference from background noise, so even the quietest leaks can be heard more easily on pipes of nearly all sizes and materials, including asbestos cement, copper, galvanized steel, polyvinyl chloride (PVC), concrete and ductile iron and cast iron. Booth #515Formadrain

Resin hardening on you? Try FORMADRAIN‘s new 30 days open time resin. That much work time means no liners lost over time restraints or unforeseen difficulties, with no unneeded rushes that can be costly. Your crew can focus on their work without stress. Tired of preparing the liners? Formadrain ships them pre-wet. If you add this to its low start-up cost and our competitive material prices, as well as its live technical support 8 a.m. to 8 p.m. EST, flexibility of your schedule has never been so successfully cost-effective. FORMADRAIN is a steam-cured, pull-in-place lining system used for lining laterals, spot repairs, industrial process pipes and LMC Lateral-Main-Connections. Pipe diameters range from 2 to 48 in. One of the great advantages of steam curing is cure control, and that means quality control. Booth #915

Resin hardening on you? Try FORMADRAIN‘s new 30 days open time resin. That much work time means no liners lost over time restraints or unforeseen difficulties, with no unneeded rushes that can be costly. Your crew can focus on their work without stress. Tired of preparing the liners? Formadrain ships them pre-wet. If you add this to its low start-up cost and our competitive material prices, as well as its live technical support 8 a.m. to 8 p.m. EST, flexibility of your schedule has never been so successfully cost-effective. FORMADRAIN is a steam-cured, pull-in-place lining system used for lining laterals, spot repairs, industrial process pipes and LMC Lateral-Main-Connections. Pipe diameters range from 2 to 48 in. One of the great advantages of steam curing is cure control, and that means quality control. Booth #915Godwin Pumps (Xylem Dewatering Solutions)

Godwin Pumps, manufacturer of the Dri-Prime automatic self-priming, dry-running pump, announces its NC line of pumps. The Godwin Dri-Prime NC150M is an extremely powerful yet compact pump with flow to 1,767 gpm and discharge heads to 195 ft. NC Series pumps deliver sustained high efficiency, resulting in lower energy and fuel costs, while reducing unplanned downtime. This makes the NC150M a best-in-class portable pump suitable for both sewage and clean water applications. The Dri-Prime NC150M features an automatic, self-priming system that primes and re-primes from dry to 28 ft without operator assistance or foot valve control. It incorporates Flygt N-technology for non-clog performance, sustained high efficiency and long-term energy/fuel savings. The NC150M can be customized with a diesel engine or electric motor, highway trailer- or skid-mounted or quiet enclosure. It is also available as a Godwin DBS for pump station backup. Booth #907

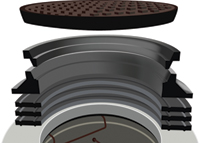

Godwin Pumps, manufacturer of the Dri-Prime automatic self-priming, dry-running pump, announces its NC line of pumps. The Godwin Dri-Prime NC150M is an extremely powerful yet compact pump with flow to 1,767 gpm and discharge heads to 195 ft. NC Series pumps deliver sustained high efficiency, resulting in lower energy and fuel costs, while reducing unplanned downtime. This makes the NC150M a best-in-class portable pump suitable for both sewage and clean water applications. The Dri-Prime NC150M features an automatic, self-priming system that primes and re-primes from dry to 28 ft without operator assistance or foot valve control. It incorporates Flygt N-technology for non-clog performance, sustained high efficiency and long-term energy/fuel savings. The NC150M can be customized with a diesel engine or electric motor, highway trailer- or skid-mounted or quiet enclosure. It is also available as a Godwin DBS for pump station backup. Booth #907Hamilton Kent

The Lifespan System is a watertight, corrosion-proof, non-conductive, locking, rubber manhole frame and cast-iron cover system that prevents rain-derived inflow from entering underground structures and sanitary sewer systems through the top of the manhole. The system has been tested to easily withstand 5 psi of water pressure, so it performs well in areas where heavy rains leave manhole covers under water. Lifespan has also been AASHTO H-25 load tested, making it perfectly suited for heavy traffic areas. Rehabilitation and installation crews like how easily they can handle the frame as it weighs only 55 lbs. The system’s tapered risers allow for a simple adjustment of the frame to match virtually any surface grade. The locking mechanism used by Lifespan deters unauthorized access and manhole cover theft. Booth #424

The Lifespan System is a watertight, corrosion-proof, non-conductive, locking, rubber manhole frame and cast-iron cover system that prevents rain-derived inflow from entering underground structures and sanitary sewer systems through the top of the manhole. The system has been tested to easily withstand 5 psi of water pressure, so it performs well in areas where heavy rains leave manhole covers under water. Lifespan has also been AASHTO H-25 load tested, making it perfectly suited for heavy traffic areas. Rehabilitation and installation crews like how easily they can handle the frame as it weighs only 55 lbs. The system’s tapered risers allow for a simple adjustment of the frame to match virtually any surface grade. The locking mechanism used by Lifespan deters unauthorized access and manhole cover theft. Booth #424 HDD Broker

HDD Broker

HDD Broker has been the used HDD equipment leader for more than 10 years and is now pleased to announce that the same superior service and technology will now be expanded into plow and trenching equipment as well. With this expansion, HDD Broker now services all of the underground utility installation equipment needs of its customers around the world. Better Service. Better Selection. Simply Better. Booth #418

HOBAS Pipe USA

HOBAS centrifugally cast, fiberglass-reinforced, polymer mortar pipe (CCFRPM) provides inherent corrosion resistance, superior hydraulics and a long, maintenance-free life. Key applications are sanitary and storm sewers, potable water and corrosive environments. It is ideal for nearly every trenchless application, including sliplining, jacking, microtunneling, two-pass tunnel and casing carrier for both pressure and gravity applications. HOBAS pipe can be found in the infrastructures of most U.S. municipalities and is ideal in new construction and rehab for critical applications. Sections join with push-together, leak-free, gasket sealed couplings. Its hydraulic characteristics provide maximum flow recovery. Smaller installation pits and longer pushes minimize surface disruption. Non-pressure and pressure classes are manufactured in diameters from 18 to 120 in. Booth #412

HOBAS centrifugally cast, fiberglass-reinforced, polymer mortar pipe (CCFRPM) provides inherent corrosion resistance, superior hydraulics and a long, maintenance-free life. Key applications are sanitary and storm sewers, potable water and corrosive environments. It is ideal for nearly every trenchless application, including sliplining, jacking, microtunneling, two-pass tunnel and casing carrier for both pressure and gravity applications. HOBAS pipe can be found in the infrastructures of most U.S. municipalities and is ideal in new construction and rehab for critical applications. Sections join with push-together, leak-free, gasket sealed couplings. Its hydraulic characteristics provide maximum flow recovery. Smaller installation pits and longer pushes minimize surface disruption. Non-pressure and pressure classes are manufactured in diameters from 18 to 120 in. Booth #412ICON Tunnel Systems

Inserta Fittings Co.

Inserta Fittings Co. introduces a new, easy-to-install wye fitting for tapping a lateral connection into most types and sizes of mainline pipe or structures. The INSERTA WYE connects to the pipe, eliminating the need to dig underneath. No securing straps are required. INSERTA WYE meets ASTM 3212 using air pressure and is watertight to meet the requirements for storm and sanitary sewer lines. Available in both 4- and 6-in. inlets, the INSERTA WYE can be used to connect corrugated, solid wall, profile wall and concrete pipe regardless of manufacturer. With an easy-to-use hand drill and drill guide, a watertight wye connection can be achieved in just a few minutes saving the contractor time and money. Booth #1026

Inserta Fittings Co. introduces a new, easy-to-install wye fitting for tapping a lateral connection into most types and sizes of mainline pipe or structures. The INSERTA WYE connects to the pipe, eliminating the need to dig underneath. No securing straps are required. INSERTA WYE meets ASTM 3212 using air pressure and is watertight to meet the requirements for storm and sanitary sewer lines. Available in both 4- and 6-in. inlets, the INSERTA WYE can be used to connect corrugated, solid wall, profile wall and concrete pipe regardless of manufacturer. With an easy-to-use hand drill and drill guide, a watertight wye connection can be achieved in just a few minutes saving the contractor time and money. Booth #1026Insituform Technologies

Fibrwrap Construction specializes in the application of Fyfe Co.’s Tyfo Fibrwrap composite systems. The Fibrwrap product is a fiber-reinforced polymer (FRP) that helps strengthen various structures, including buildings, bridges, pipelines, tanks and other commercial structures. The patented process has successfully rehabilitated pipelines worldwide ranging from 36 to 201 in. in diameter. Booth #913

Fibrwrap Construction specializes in the application of Fyfe Co.’s Tyfo Fibrwrap composite systems. The Fibrwrap product is a fiber-reinforced polymer (FRP) that helps strengthen various structures, including buildings, bridges, pipelines, tanks and other commercial structures. The patented process has successfully rehabilitated pipelines worldwide ranging from 36 to 201 in. in diameter. Booth #913Interplastic Corp.

Interplastic Corp. has commercialized its styrene-free, no-HAP, no-VOC ECO Series resin for use in the cured-in-place pipe (CIPP) process for gravity pipelines. This new product, VE8295, offers the ease in processing, mechanical properties, corrosion resistance and long life of a standard CIPP resin. Interplastic Corp. is a specialty chemical company with its headquarters in St. Paul, Minn. Its Thermoset Resins Division focuses on the production and distribution of unsaturated polyester, vinyl ester resins, gel coats, colorants, putties and adhesives for the composites and cast polymer industries. The Molding Products Division is a leader in the production of sheet molding compounds and other thermoset molding materials. Interplastic’s North American Composites division is a national, full-service supplier to these same industries. Interplastic Corp.’s Thermoset Resins Division is ISO 9001:2008 and ISO 14001:2004 certified. Booth #500

Jack Doheny Companies

Jack Doheny Companies recently placed the single largest order by a single firm for truck-mounted combination sewer cleaners, hydro excavators and industrial vacuum trucks. This order — more than 250 units — expands the largest and newest rental fleet of its kind in the industry. “The purchase will increase the value of our fleet by over $40 million,” said Dan Weber, president of Jack Doheny Companies. “We made this purchase to help meet the rapidly growing demand for our rental products and adequately support our loyal customer base.” Along with these new trucks, Jack Doheny Companies is growing its presence in the Gulf and West coasts, upper Midwest and Canada. Establishing and staffing world class service centers with qualified personnel is a vital part of the overall operation. The expanded fleet and service locations will grant customers unparalleled access to the quality equipment and service that Doheny Companies represents. Booth #712

Jack Doheny Companies recently placed the single largest order by a single firm for truck-mounted combination sewer cleaners, hydro excavators and industrial vacuum trucks. This order — more than 250 units — expands the largest and newest rental fleet of its kind in the industry. “The purchase will increase the value of our fleet by over $40 million,” said Dan Weber, president of Jack Doheny Companies. “We made this purchase to help meet the rapidly growing demand for our rental products and adequately support our loyal customer base.” Along with these new trucks, Jack Doheny Companies is growing its presence in the Gulf and West coasts, upper Midwest and Canada. Establishing and staffing world class service centers with qualified personnel is a vital part of the overall operation. The expanded fleet and service locations will grant customers unparalleled access to the quality equipment and service that Doheny Companies represents. Booth #712LMK

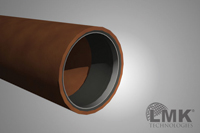

LMK presents the Insignia Hydrophilic Sealing System. Your search for a durable, watertight seal stops here. The LMK Insignia Sealing System is the latest addition to LMK’s line of quality products for sewer rehabilitation. LMK offers Insignia O-rings, Connection Hats and End Seal Sleeves as solutions to groundwater infiltration at lateral/mainline connections and manhole penetrations. Insignia Seals swell three to five times on contact with water, forming a water-tight seal. The Insignia line of products is compatible with pull-in-place, as well as inversion methods of lining. Insignia offers many advantages to the Insignia seals including a low profile, larger surface area seamlessly molded 360 compression gasket to ensure a strong, even seal. Insignia inhibits groundwater infiltration, enhancing the quality of the CIPP lining, thus maximizing the efficiency of the sewer. Don’t just reduce I&I, eliminate it. Booth #619

LMK presents the Insignia Hydrophilic Sealing System. Your search for a durable, watertight seal stops here. The LMK Insignia Sealing System is the latest addition to LMK’s line of quality products for sewer rehabilitation. LMK offers Insignia O-rings, Connection Hats and End Seal Sleeves as solutions to groundwater infiltration at lateral/mainline connections and manhole penetrations. Insignia Seals swell three to five times on contact with water, forming a water-tight seal. The Insignia line of products is compatible with pull-in-place, as well as inversion methods of lining. Insignia offers many advantages to the Insignia seals including a low profile, larger surface area seamlessly molded 360 compression gasket to ensure a strong, even seal. Insignia inhibits groundwater infiltration, enhancing the quality of the CIPP lining, thus maximizing the efficiency of the sewer. Don’t just reduce I&I, eliminate it. Booth #619Logiball Inc.

Logiball manufactures a complete line of multi-size reinforced inflatable plugs used for testing bypassing and controlling the flow in gravity sewers. Logiball also manufactures a complete line of carrier packers for the installation of trenchless point repairs (4- to 36-in. pipes). Over the years Logiball has developed state-of–the-art test-and-seal grouting packers for mainline joints (6- to 144-in.), elliptical pipes, lateral pipe joints (4- to 8-in.) and lateral connection packers (6- to 24-in. mainlines with 4- to 6-in. laterals up to 30 ft from the connection).Over the last decade the Logiball Lateral Packers have been used to test and seal over 100,000 lateral connections. For quality field proven products and fast service, contact Logiball. Booth #812

Logiball manufactures a complete line of multi-size reinforced inflatable plugs used for testing bypassing and controlling the flow in gravity sewers. Logiball also manufactures a complete line of carrier packers for the installation of trenchless point repairs (4- to 36-in. pipes). Over the years Logiball has developed state-of–the-art test-and-seal grouting packers for mainline joints (6- to 144-in.), elliptical pipes, lateral pipe joints (4- to 8-in.) and lateral connection packers (6- to 24-in. mainlines with 4- to 6-in. laterals up to 30 ft from the connection).Over the last decade the Logiball Lateral Packers have been used to test and seal over 100,000 lateral connections. For quality field proven products and fast service, contact Logiball. Booth #812MaxLiner

As the first cured-in-place pipe (CIPP) system to receive code-compliancy from the International Code Council (ICC-ES), MaxLiner, a leader in lateral and vertical pipe repair, offers complete solutions, including lateral sealing. With ICC-ES compliancy, MaxLiner makes it easier than ever for installers to reach not only laterals, but also the toughest vertical pipes and downspouts. MaxLiner continues to lead trenchless innovation with MaxLiner CLS. This Complete Lateral System seals lateral pipelines at the connection interface starting from inside the mainline and out into the lateral. The lining system allows installation even in 90 degree bends. What’s more, lateral liners can be lined even after the main liner has been installed, and laterals without a clean-out can be lined from the mainline pipe. Whether your needs are for lateral, vertical or complete rehabilitation solutions, contact MaxLiner. Booth #1206

As the first cured-in-place pipe (CIPP) system to receive code-compliancy from the International Code Council (ICC-ES), MaxLiner, a leader in lateral and vertical pipe repair, offers complete solutions, including lateral sealing. With ICC-ES compliancy, MaxLiner makes it easier than ever for installers to reach not only laterals, but also the toughest vertical pipes and downspouts. MaxLiner continues to lead trenchless innovation with MaxLiner CLS. This Complete Lateral System seals lateral pipelines at the connection interface starting from inside the mainline and out into the lateral. The lining system allows installation even in 90 degree bends. What’s more, lateral liners can be lined even after the main liner has been installed, and laterals without a clean-out can be lined from the mainline pipe. Whether your needs are for lateral, vertical or complete rehabilitation solutions, contact MaxLiner. Booth #1206McLaughlin Group

The ON Target auger boring system from McLaughlin head allows contractors to not only control horizontal directional changes, but also allows for lateral changes. The cutting path — grade and lateral movement — of the steering head is controlled by hydraulic actuated panels that open and close to keep the head on the intended path. A control station features a hydraulic power pack to control the movement of the steering head, and a built-in water level helps monitor grade throughout the bore. Two halogen lights in the control station indicate lateral (left and right) steering head movements. Up until now auger boring contractors were limited to a steering head that offered only horizontal or grade (up and down) direction changes during the bore. The ON Target system allows contractors to also control the direction of the bore in a lateral (left to right) movement, providing more accuracy for difficult on-grade bores. Booth #1014

The ON Target auger boring system from McLaughlin head allows contractors to not only control horizontal directional changes, but also allows for lateral changes. The cutting path — grade and lateral movement — of the steering head is controlled by hydraulic actuated panels that open and close to keep the head on the intended path. A control station features a hydraulic power pack to control the movement of the steering head, and a built-in water level helps monitor grade throughout the bore. Two halogen lights in the control station indicate lateral (left and right) steering head movements. Up until now auger boring contractors were limited to a steering head that offered only horizontal or grade (up and down) direction changes during the bore. The ON Target system allows contractors to also control the direction of the bore in a lateral (left to right) movement, providing more accuracy for difficult on-grade bores. Booth #1014Michels

Michels promotes advanced Direct Pipe technology in instances when expected soil conditions could prove detrimental to the successful HDD installation of a utility line. Direct Pipe is a trenchless form of construction used to install large diameter, prefabricated pipe in one nearly continuous step. Direct Pipe is at its best when installing pipe through mixed soil conditions or unconsolidated rock formations non-conducive to HDD, or when performing installations requiring minimal cover. Because equipment is only required on one side of a crossing, Direct Pipe can be ideal in urban settings. Michels recently put Direct Pipe technology to the test with the successful installation of a challenging 24-in. HDD crossing of the Chemung River in Corning, N.Y., for Empire Pipeline, Inc. Michels used Direct Pipe to successfully install 480 ft of 42-in. heavy-wall surface casing down to the rock while working in a mixed soil matrix of heavy gravels and cobble. Booth #501

Michels promotes advanced Direct Pipe technology in instances when expected soil conditions could prove detrimental to the successful HDD installation of a utility line. Direct Pipe is a trenchless form of construction used to install large diameter, prefabricated pipe in one nearly continuous step. Direct Pipe is at its best when installing pipe through mixed soil conditions or unconsolidated rock formations non-conducive to HDD, or when performing installations requiring minimal cover. Because equipment is only required on one side of a crossing, Direct Pipe can be ideal in urban settings. Michels recently put Direct Pipe technology to the test with the successful installation of a challenging 24-in. HDD crossing of the Chemung River in Corning, N.Y., for Empire Pipeline, Inc. Michels used Direct Pipe to successfully install 480 ft of 42-in. heavy-wall surface casing down to the rock while working in a mixed soil matrix of heavy gravels and cobble. Booth #501Miller Pipeline Corp.

Miller Pipeline Corp.’s WEKO-SEAL, the industry’s leading internal joint seal technology, is used extensively for internally resolving joint leakage, punctures and crack repairs in pipelines ranging in diameter from 18 in. and larger. With over 225,000 installations to date, the WEKO-SEAL has become the repair method of choice for many contractors, municipalities, gas utilities, industrial and nuclear power customers throughout the United States. All installations are completed by Miller’s experienced confined space technicians, using time proven techniques to provide permanent, flexible, leak-proof repairs. This man-entry repair system is a flexible rubber leak clamp that ensures a noncorrodible, bottle-tight seal around the full inside circumference at every installed location, while offering significant savings over conventional external repair methods using individual excavations. Booth #821

Miller Pipeline Corp.’s WEKO-SEAL, the industry’s leading internal joint seal technology, is used extensively for internally resolving joint leakage, punctures and crack repairs in pipelines ranging in diameter from 18 in. and larger. With over 225,000 installations to date, the WEKO-SEAL has become the repair method of choice for many contractors, municipalities, gas utilities, industrial and nuclear power customers throughout the United States. All installations are completed by Miller’s experienced confined space technicians, using time proven techniques to provide permanent, flexible, leak-proof repairs. This man-entry repair system is a flexible rubber leak clamp that ensures a noncorrodible, bottle-tight seal around the full inside circumference at every installed location, while offering significant savings over conventional external repair methods using individual excavations. Booth #821Perma-Liner

Perma-Liner’s Continuous Lining Top Gun will work with diameters of 6 to 24 in. The Top Gun performs continuous air inversion lining of more than 600 ft, averaging 1 ft of liner inverted per 1.5 seconds. Steam cure is used for rapid cure times which allow the installer the ability to complete multiple shots in one-day. Perma-Liner’s Top Gun comes as a Turn-Key installation system, complete with manifold, hoses and more. Five days of on-site training and certification are also included. Perma-Liner also provides 24/7 ongoing technical support. Booth #601

Perma-Liner’s Continuous Lining Top Gun will work with diameters of 6 to 24 in. The Top Gun performs continuous air inversion lining of more than 600 ft, averaging 1 ft of liner inverted per 1.5 seconds. Steam cure is used for rapid cure times which allow the installer the ability to complete multiple shots in one-day. Perma-Liner’s Top Gun comes as a Turn-Key installation system, complete with manifold, hoses and more. Five days of on-site training and certification are also included. Perma-Liner also provides 24/7 ongoing technical support. Booth #601Pipeline Renewal Technologies

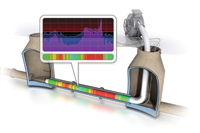

Using patented technology, the VeriCure system from Pipeline Renewal Technologies monitors cure temperature continuously along the full length of a CIPP liner during installation. This information helps ensure storm and sewer lines are rehabilitated to specification and perform as intended. Designed to distinguish even small thermal variances, VeriCure measures average temperature in successive 1.5-ft zones — a spatial resolution at least seven times that of other technologies. And with measurement probes costing less than a dollar per foot, VeriCure makes it affordable to prevent costly lifts, delamination, over-tensioning and environmental contamination. VeriCure indicates exactly when the liner cure goes exothermic and when cure and cool-down are complete. This means no wasting fuel and crew time overcooking the liner and no risk of failure due to undercooked midpoints. VeriCure measurement probes are unobtrusive; they measure just 3 mm in diameter and introduce no sensitive electronics into the pipe. Booth #413

Using patented technology, the VeriCure system from Pipeline Renewal Technologies monitors cure temperature continuously along the full length of a CIPP liner during installation. This information helps ensure storm and sewer lines are rehabilitated to specification and perform as intended. Designed to distinguish even small thermal variances, VeriCure measures average temperature in successive 1.5-ft zones — a spatial resolution at least seven times that of other technologies. And with measurement probes costing less than a dollar per foot, VeriCure makes it affordable to prevent costly lifts, delamination, over-tensioning and environmental contamination. VeriCure indicates exactly when the liner cure goes exothermic and when cure and cool-down are complete. This means no wasting fuel and crew time overcooking the liner and no risk of failure due to undercooked midpoints. VeriCure measurement probes are unobtrusive; they measure just 3 mm in diameter and introduce no sensitive electronics into the pipe. Booth #413Pure Technologies

Pure Technologies announces that it is expanding its services in pipe wall assessment with a state-of-the-art in-line inspection tool that measures wall thickness utilizing high-resolution magnetic flux leakage (MFL) technology. MFL is an electromagnetic method of non-destructive testing that is used to detect corrosion, pitting and wall loss in lined an unlined metallic pipelines. Pure adds this tool to its existing SmartBall, Sahara and PipeDiver pipe wall assessment technologies to now offer the most comprehensive assessment solutions for metallic water and wastewater pipelines. For more information about its metallic and PCCP pipeline condition assessment solutions, stop by Pure’s booth. Booth #918

Pure Technologies announces that it is expanding its services in pipe wall assessment with a state-of-the-art in-line inspection tool that measures wall thickness utilizing high-resolution magnetic flux leakage (MFL) technology. MFL is an electromagnetic method of non-destructive testing that is used to detect corrosion, pitting and wall loss in lined an unlined metallic pipelines. Pure adds this tool to its existing SmartBall, Sahara and PipeDiver pipe wall assessment technologies to now offer the most comprehensive assessment solutions for metallic water and wastewater pipelines. For more information about its metallic and PCCP pipeline condition assessment solutions, stop by Pure’s booth. Booth #918 Rain for Rent

Rain for Rent, one of the top rental equipment companies in the United States and a Silver Sponsor of the 2012 No-Dig Show, combines pumps, pipe, tanks and filtration systems into creative, turn-key solutions for liquid-handling problems. Rain for Rent offers one-stop shopping for your liquid-handling needs, from engineering to onsite personnel, available 24 hours a day, 365 days a year. Rain for Rent’s 8-in. DV-200c Power Prime pump offers superior fuel efficiency, increased hydraulic efficiencies up to 81 percent, solids handling up to 3.375 in., flow capability to 4,500 gpm and head capability to 260 ft. A Sound Attenuated (SA) enclosure option is available, which reduces operation noise to as low as 72 dB at 23 ft. Booth #506

Rain for Rent, one of the top rental equipment companies in the United States and a Silver Sponsor of the 2012 No-Dig Show, combines pumps, pipe, tanks and filtration systems into creative, turn-key solutions for liquid-handling problems. Rain for Rent offers one-stop shopping for your liquid-handling needs, from engineering to onsite personnel, available 24 hours a day, 365 days a year. Rain for Rent’s 8-in. DV-200c Power Prime pump offers superior fuel efficiency, increased hydraulic efficiencies up to 81 percent, solids handling up to 3.375 in., flow capability to 4,500 gpm and head capability to 260 ft. A Sound Attenuated (SA) enclosure option is available, which reduces operation noise to as low as 72 dB at 23 ft. Booth #506RapidView IBAK North America

RapidView IBAK North America is pleased to introduce the latest evolution of the ORION 2 Camera system. A revolution in compact design and functionality, the new higher resolution ORION 2.5 boasts pan, tilt and now zoom functionality while maintaining a wide angle of view. It can rotate automatically around pipe joints and provides a picture that is always right side up. Incredible low-light camera technology allows users to inspect very large pipelines (over 60 in.) with this very small camera. The new ORION can be used on a pushrod, mainline tractor or as the launch camera on a lateral lunching system. As with all IBAK equipment, the camera is pressurized to in order to provide added peace of mind and a diagnostic warning in the case of a pressure loss during operations. The ORION 2.5 is also capable of using its on-board laser system to measure defects, diameter and pipe deformation while inside the pipeline. Booth #417

RapidView IBAK North America is pleased to introduce the latest evolution of the ORION 2 Camera system. A revolution in compact design and functionality, the new higher resolution ORION 2.5 boasts pan, tilt and now zoom functionality while maintaining a wide angle of view. It can rotate automatically around pipe joints and provides a picture that is always right side up. Incredible low-light camera technology allows users to inspect very large pipelines (over 60 in.) with this very small camera. The new ORION can be used on a pushrod, mainline tractor or as the launch camera on a lateral lunching system. As with all IBAK equipment, the camera is pressurized to in order to provide added peace of mind and a diagnostic warning in the case of a pressure loss during operations. The ORION 2.5 is also capable of using its on-board laser system to measure defects, diameter and pipe deformation while inside the pipeline. Booth #417Raven Lining Systems

Raven Lining Systems offers a full scope of cementitious products to complement its well established epoxy lining system. Through its network of Certified Applicators, Raven Lining Systems provides products that cover any issue from masonry to concrete structures. Raven cement products can plug major leaks, repair badly deteriorated substrates and provide an underlay before applying Raven epoxy coatings. Raven Lining Systems continues to expand its product line giving its Certified Applicators all the tools necessary to provide quality products and services for their clients. Booth # 944

Raven Lining Systems offers a full scope of cementitious products to complement its well established epoxy lining system. Through its network of Certified Applicators, Raven Lining Systems provides products that cover any issue from masonry to concrete structures. Raven cement products can plug major leaks, repair badly deteriorated substrates and provide an underlay before applying Raven epoxy coatings. Raven Lining Systems continues to expand its product line giving its Certified Applicators all the tools necessary to provide quality products and services for their clients. Booth # 944Reline America

Reline America Inc. is the North American manufacturer of the BLUE-TEK and BLUE-TEK AR3 family of liners. As a high-quality pipe renewal technology, Reline America liners are manufactured through a patented process of spirally-wound, fiberglass reinforced, ultra-violet cured-in-place pipe and delivered onsite ready for installation. Under the supervision of its engineers and full-time laboratory staff, these liners are wetted out in an ISO 9001:2008 registered manufacturing facility. It’s installed with the award-winning, tamper-proof, computerized Quality-Tracker System that documents every foot of the curing process, BLUE-TEK liners are available in lengths up to 1,000 ft and can be manufactured to fit any diameter from 6 to 48 in. Booth #1101

Reline America Inc. is the North American manufacturer of the BLUE-TEK and BLUE-TEK AR3 family of liners. As a high-quality pipe renewal technology, Reline America liners are manufactured through a patented process of spirally-wound, fiberglass reinforced, ultra-violet cured-in-place pipe and delivered onsite ready for installation. Under the supervision of its engineers and full-time laboratory staff, these liners are wetted out in an ISO 9001:2008 registered manufacturing facility. It’s installed with the award-winning, tamper-proof, computerized Quality-Tracker System that documents every foot of the curing process, BLUE-TEK liners are available in lengths up to 1,000 ft and can be manufactured to fit any diameter from 6 to 48 in. Booth #1101SAERTEX multiCom

SAERTEX multiCom is a global manufacturer offering environmentally responsible rehabilitation solutions. The UV cure SAERTEX-LINER offers a tight-fitting, high-strength, environmentally friendly product for the rehabilitation of sanitary sewers and storm pipes. With its high flexural modulus and flexural strength, the SAERTEX-LINER offers a strong liner with a thin wall thickness and a service life of 70 years. The UV cure SAERTEX-LINER offers fast installation times, less disruption and a 90 percent smaller carbon foot print than hot water cure felt liners. The SAERTEX-LINER is manufactured in 6- to 50-in. diameters, as well as irregular shapes and transitions. SAERTEX multiCom has the latest UV-curing technology available for rent, lease and purchase. SAERTEX’s experienced technicians will train and support you on all aspects of installing the SAERTEX-LINER. SAERTEX is ISO-9001 certified and proud to celebrate 10 years of manufacturing in Huntersville, N.C. Booth #113

SAERTEX multiCom is a global manufacturer offering environmentally responsible rehabilitation solutions. The UV cure SAERTEX-LINER offers a tight-fitting, high-strength, environmentally friendly product for the rehabilitation of sanitary sewers and storm pipes. With its high flexural modulus and flexural strength, the SAERTEX-LINER offers a strong liner with a thin wall thickness and a service life of 70 years. The UV cure SAERTEX-LINER offers fast installation times, less disruption and a 90 percent smaller carbon foot print than hot water cure felt liners. The SAERTEX-LINER is manufactured in 6- to 50-in. diameters, as well as irregular shapes and transitions. SAERTEX multiCom has the latest UV-curing technology available for rent, lease and purchase. SAERTEX’s experienced technicians will train and support you on all aspects of installing the SAERTEX-LINER. SAERTEX is ISO-9001 certified and proud to celebrate 10 years of manufacturing in Huntersville, N.C. Booth #113Sauereisen

Sauereisen SewerGardTM No. 210X is a protective lining specifically formulated for municipal wastewater environments. SewerGard No. 210X provides a chemical-resistant barrier for concrete, masonry, brick and steel substrates. SewerGardTM No. 210X has the ability to build up to 125 mils in a single coat and offers strengths more than 15,000 psi. What is exceptionally exciting is 210X’s ability to maintain an elongation of more than 12 percent. As a 100 percent solids epoxy polymer, No. 210X is specified to protect infrastructure throughout the wastewater industry. Applications range from manholes and lift stations within collection systems to tankage, structural steel and secondary containment at treatment plants. Installation of SewerGard No. 210X is easily completed using airless spray equipment, plural component spray equipment or roller. Booth #707

Sauereisen SewerGardTM No. 210X is a protective lining specifically formulated for municipal wastewater environments. SewerGard No. 210X provides a chemical-resistant barrier for concrete, masonry, brick and steel substrates. SewerGardTM No. 210X has the ability to build up to 125 mils in a single coat and offers strengths more than 15,000 psi. What is exceptionally exciting is 210X’s ability to maintain an elongation of more than 12 percent. As a 100 percent solids epoxy polymer, No. 210X is specified to protect infrastructure throughout the wastewater industry. Applications range from manholes and lift stations within collection systems to tankage, structural steel and secondary containment at treatment plants. Installation of SewerGard No. 210X is easily completed using airless spray equipment, plural component spray equipment or roller. Booth #707Sekisui SPR Americas LLC

TT Technologies

In addition to its line of trenchless piercing, pipe ramming and pipe bursting tools, TT Technologies will display its new Grundopit-K keyhole mini-directional drill at the No-Dig show. The new Grundopit-K is designed to operate out of a keyhole excavation for the trenchless installation of gas and water service connections. The unit is fully automated and able to work in a 24-in. diameter excavation. The unit is able to install service installations up to 2 in. in diameter, at lengths up to 100 ft. Attendees will also be able to see the complete line of Grundomat piercing tools, the Grundoburst static pipe bursting system, Grundocrack pneumatic pipe bursting tools, as well as Grundoram pipe ramming tools. Booth #801

In addition to its line of trenchless piercing, pipe ramming and pipe bursting tools, TT Technologies will display its new Grundopit-K keyhole mini-directional drill at the No-Dig show. The new Grundopit-K is designed to operate out of a keyhole excavation for the trenchless installation of gas and water service connections. The unit is fully automated and able to work in a 24-in. diameter excavation. The unit is able to install service installations up to 2 in. in diameter, at lengths up to 100 ft. Attendees will also be able to see the complete line of Grundomat piercing tools, the Grundoburst static pipe bursting system, Grundocrack pneumatic pipe bursting tools, as well as Grundoram pipe ramming tools. Booth #801Underground Solutions Inc.

Underground Solutions Inc. (UGSI) provides infrastructure technologies for water and sewer applications. UGSI’s Fusible PVC pipe products are available in diameters from 4 to 36 in., including Fusible C-900, Fusible C-905 and FPVC, and use patented technology to produce a fused monolithic, fully-restrained, gasket-free, leak-free piping system ideal for trenchless (horizontal directional drilling, pipe bursting and sliplining) or conventional open-cut installations. UGSI’s Duraliner is a patented, close-fit pipeline renewal system that creates a stand-alone structural liner (exceeds Class IV AWWA M-28). The combination of standard fittings, as well as less weight and more flow for a given pressure class versus other thermoplastic pipes ensure that Fusible PVC pipe brings greater economy to most pipeline projects. Booth #613

Underground Solutions Inc. (UGSI) provides infrastructure technologies for water and sewer applications. UGSI’s Fusible PVC pipe products are available in diameters from 4 to 36 in., including Fusible C-900, Fusible C-905 and FPVC, and use patented technology to produce a fused monolithic, fully-restrained, gasket-free, leak-free piping system ideal for trenchless (horizontal directional drilling, pipe bursting and sliplining) or conventional open-cut installations. UGSI’s Duraliner is a patented, close-fit pipeline renewal system that creates a stand-alone structural liner (exceeds Class IV AWWA M-28). The combination of standard fittings, as well as less weight and more flow for a given pressure class versus other thermoplastic pipes ensure that Fusible PVC pipe brings greater economy to most pipeline projects. Booth #613Vaporooter

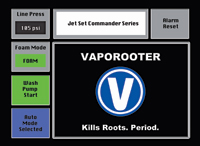

The Jet Set Commander is a state-of-the-art system for the on-demand application of Sanafoam Vaprooter II, a chemical root control product formulated to eliminate roots and resulting blockages in sanitary sewer systems. The Commander can be installed on virtually any make or model of hydro-jetter or combination sewer cleaning truck with a front, mid or rear mounted reel. The Commander is easily removable when not in use and can be installed on a standard receiver hitch or on the chassis in the place of a tool box. The Commander is offered as a factory installed or aftermarket option by most major sewer truck manufacturers and their dealers or may be installed by Vaporooter. Booth #109

The Jet Set Commander is a state-of-the-art system for the on-demand application of Sanafoam Vaprooter II, a chemical root control product formulated to eliminate roots and resulting blockages in sanitary sewer systems. The Commander can be installed on virtually any make or model of hydro-jetter or combination sewer cleaning truck with a front, mid or rear mounted reel. The Commander is easily removable when not in use and can be installed on a standard receiver hitch or on the chassis in the place of a tool box. The Commander is offered as a factory installed or aftermarket option by most major sewer truck manufacturers and their dealers or may be installed by Vaporooter. Booth #109Vermeer Corp.

New for 2012, Vermeer introduces a horizontal directional drill for the unique demands of mixed ground conditions, including rock. The D36x50R Series II with MAGnum technology is based on the design of the D36x50 Series II Navigator, but has been modified to accommodate rock drilling. The D36x50R Series II is equipped with the rock-focused MAGnum drilling system. Using rapidly rotating magnets of alternating polarity within the carriage assembly, a high frequency percussive action is generated to fracture and effectively bore through tough formations, including solid rock. This hammer technology was developed in collaboration with FlexiDRILL, a New Zealand-based engineering company, and is licensed for exclusive distribution by Vermeer. Booth #901

New for 2012, Vermeer introduces a horizontal directional drill for the unique demands of mixed ground conditions, including rock. The D36x50R Series II with MAGnum technology is based on the design of the D36x50 Series II Navigator, but has been modified to accommodate rock drilling. The D36x50R Series II is equipped with the rock-focused MAGnum drilling system. Using rapidly rotating magnets of alternating polarity within the carriage assembly, a high frequency percussive action is generated to fracture and effectively bore through tough formations, including solid rock. This hammer technology was developed in collaboration with FlexiDRILL, a New Zealand-based engineering company, and is licensed for exclusive distribution by Vermeer. Booth #901Wachs Water Services

The Investigator is a next-generation condition assessment technology for water distribution mains. The technology operates in pressurized water mains and efficiently provides visual and leak detection assessments through a single, advanced tethered sensor. Unlike any other commercially available technology, the Investigator can be launched through fire hydrants, pressure fittings, air valves, gate valves and flow meters while the main remains in service. The Investigator is capable of travelling up to 330 ft in either direction from the insertion point — with or against the flow of water. The Investigator has a small footprint and can be operated from the back of a standard utility vehicle. The hydrophone is operated in parallel with the camera system, offering visual and acoustic data all from one operation. Booth #927

The Investigator is a next-generation condition assessment technology for water distribution mains. The technology operates in pressurized water mains and efficiently provides visual and leak detection assessments through a single, advanced tethered sensor. Unlike any other commercially available technology, the Investigator can be launched through fire hydrants, pressure fittings, air valves, gate valves and flow meters while the main remains in service. The Investigator is capable of travelling up to 330 ft in either direction from the insertion point — with or against the flow of water. The Investigator has a small footprint and can be operated from the back of a standard utility vehicle. The hydrophone is operated in parallel with the camera system, offering visual and acoustic data all from one operation. Booth #927

HDD Broker

HDD Broker