Why Certified Applicators Make the Difference in Sewer Infrastructure Rehab

Sewer infrastructure operates largely out of sight, yet any failure can bring severe consequences. Corroded manholes, compromised lift stations, and leaking or collapsed pipes can trigger environmental violations, public health risks, and soaring repair bills.

Below-grade collection systems face harsh conditions: damp environments frequently laden with hydrogen sulfide (H2S), other corrosive gases, and persistent groundwater infiltration. In such environments, even slight missteps in surface preparation or coating application can lead to premature failures. No municipality or utility wants to face these issues.

One reliable way to guard against these issues is to ensure crews are properly trained and certified in rehabilitation procedures through formal programs. Additionally, when paired with specialized materials and robust warranties, certified applicators deliver improved reliability, minimized maintenance, and extended service life for critical sewer infrastructure.

Complex Infrastructure Requires Care

Manholes, wet wells, and other below-grade assets experience constant moisture. They potentially face damaging bacterial activity, corrosive chemical exposures, and substantial physical stress (Figure 1). Hydrogen sulfide, for example, can encourage microbial-induced corrosion (MIC), which is harmful to concrete. Without a robust coating or lining, deterioration can accelerate quickly. This often leads to infiltration, exfiltration, and expensive remediation. In the worst scenarios, a total system failure can halt essential services and endanger public health.

Surface preparation lays the groundwork for success. It’s necessary to remove contaminants and moisture, seal cracks and leaks, and stabilize substrate pH before applying protective coatings or linings. Many owners invest in high-performance materials, however, the true measure of success depends on the level of application expertise. This expertise ranges from the initial prep work to the final coating inspection.

How Skilled Applicators Can Help

Rehabilitating deteriorated sewer assets demands an array of specialized skills, including:

Proper Surface Prep and Product Selection. Achieving a clean, properly profiled surface is the first step in successful rehabilitation. Trained professionals must also choose coating systems designed to handle a project’s particular environmental challenges.

Some conditions may call for a high-build epoxy or an elastomeric polyurethane, while other scenarios might need structural mortars. Experienced, formally trained teams know when to incorporate aggregates for thicker, trowel-applied section repairs or for structural reinforcement.

Correct Application Thicknesses and Holiday Testing

Even premium coatings can lose effectiveness if applied too thin or left riddled with pinholes. Certified professionals adhere to rigorous standards for final dry film thickness. They use both visual inspections and wet film thickness checks during application. Furthermore, they perform spark testing to find and fix any voids that compromise integrity.

Accurate Use of Flexible or Rigid Systems

Sewer infrastructure can shift or move, making flexibility an important consideration in some applications. In those cases, a high-build polyurethane may be more suitable than a rigid epoxy solution. At other times, a reinforced epoxy may provide the superior chemical resistance needed. Certified applicators recognize these distinctions and select the right system rather than forcing one approach for every asset.

Why Formal Certification Matters

When a contractor takes part in a recognized certification program, they gain specialized training, comprehensive product knowledge, and access to ongoing technical support. This approach helps asset owners avoid hidden quality pitfalls and deliver reliable outcomes in sewer environments.

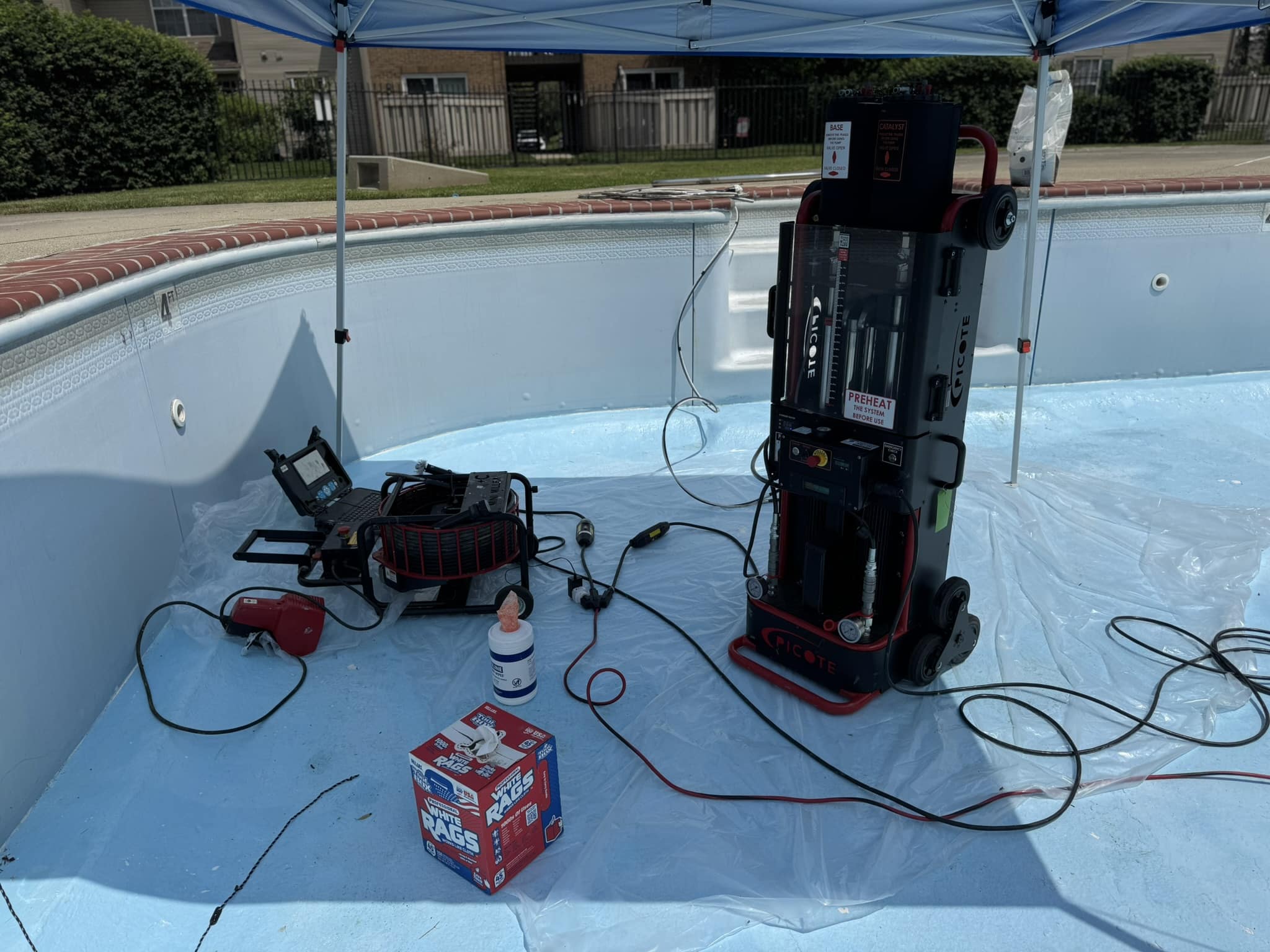

Applicators in these programs typically receive hands-on instruction in surface preparation, application methods, equipment calibration, and testing protocols (Figure 3). They also stay updated on material innovations and best-practice advancements by renewing their certifications regularly. In many cases, onsite audits verify proper prep through final inspection, helping to avoid rework or delays.

Another core advantage of this approach is the possibility of offering single-source warranties that go beyond covering just the coating material itself. Instead, these warranties often bundle workmanship with the product warranty. This combined coverage streamlines accountability and can reduce disputes. If a certified applicator fails to meet program standards, they risk losing their certification. This serves as a strong incentive for consistent quality on every job.

The Risks of Uncertified Work

When municipalities use contractors without formal certification, they risk inadequate surface preparation that fails to address concealed moisture or voids. They may also deal with unsuitable product choices or thin applications. These factors allow coatings to degrade quickly under corrosive or shifting conditions.

With no overarching certification program in place, owners often juggle separate material and labor warranties. This can lead to confusion about responsibilities when failures occur. Over time, repeated callbacks, emergency shutdowns, and mounting remediation expenses become all too familiar.

Enabling Positive Outcomes

Sewer infrastructure is both critical and susceptible to damage. Any compromise in the application process can lead to premature failures that undermine the health of entire communities. Teams that have completed rigorous certification programs provide the expertise, specialized equipment, and on-site accountability needed to install coatings and linings. This protection can last for decades.

Opting for certified contractors offers clear advantages for municipalities, utilities, engineers, and specifiers alike. These include improved asset longevity, fewer emergency repairs, and lower total lifecycle costs. By specifying that a contractor must hold an active certification, specifiers streamline the bidding process. They narrow the field to vetted and trained professionals. Meanwhile, certified contractors benefit from a strengthened market reputation, better project opportunities, and dedicated manufacturer or program support.

While not universally required, formal certifications are increasingly recognized by asset owners seeking greater reliability and the best return on their rehabilitation investments. A well-trained workforce, combined with high-performance materials and unified warranties, can produce extended service life. It also minimizes groundwater infiltration and ensures long-term peace of mind.

Paul Trautmann is marketing director for Infrastructure for Sherwin-Williams Protective & Marine. Steven Roetter, P.E., is a market segment manager for water infrastructure for Sherwin-Williams Protective & Marine.

- How to Inspect and Assess Lateral Sewer Pipes

- Spotless Sewer Lines Play a Key Role in Lining Success

- How to Develop a Cost-Benefit Analysis for Pipeline Rehabilitation vs. Replacement

- How to Apply ASCE MOP 145 to Gravity Lining Projects

- How to Prepare and Trowel-Apply for a Manhole Rehab Project

Next Up

2026 Microtunneling Short Course | May 5-7, 2026 | Scottsdale, Arizona | Learn more