Understanding Manhole Inspections and Their Role in Infrastructure Management

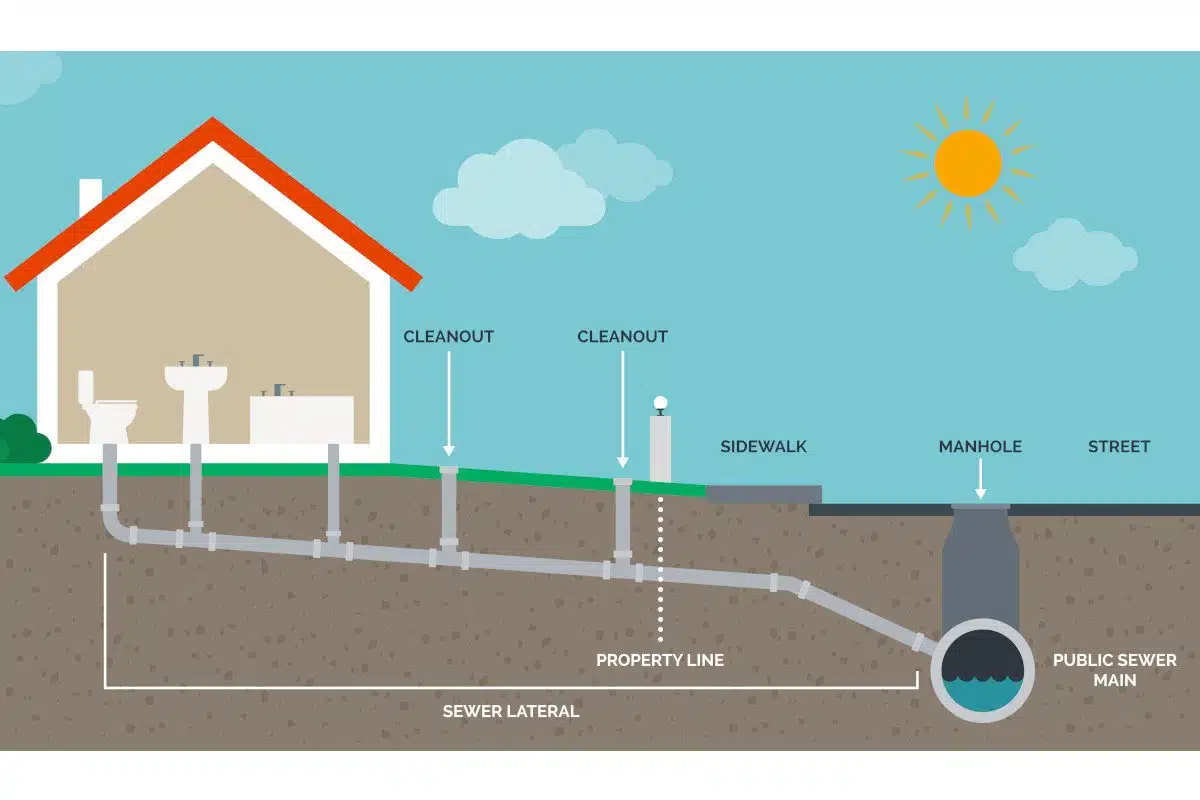

Manholes are an overlooked, yet essential component of every underground collection system. They serve as critical access points, connectors, and structural elements that influence the performance and longevity of the entire network.

Across North America, thousands of these assets are aging, and their condition directly affects system reliability, safety, and infiltration control. That’s why comprehensive manhole inspections have become a foundation of effective rehabilitation and asset management programs.

Manhole Inspection Basics

At its core, a manhole inspection is an evaluation of the structure’s physical condition, construction materials and any observed defects. Traditional inspections used to require manual entry or surface-level visual observation, but today, many municipalities and contractors rely on non-entry methods that use advanced imaging and measurement technology.

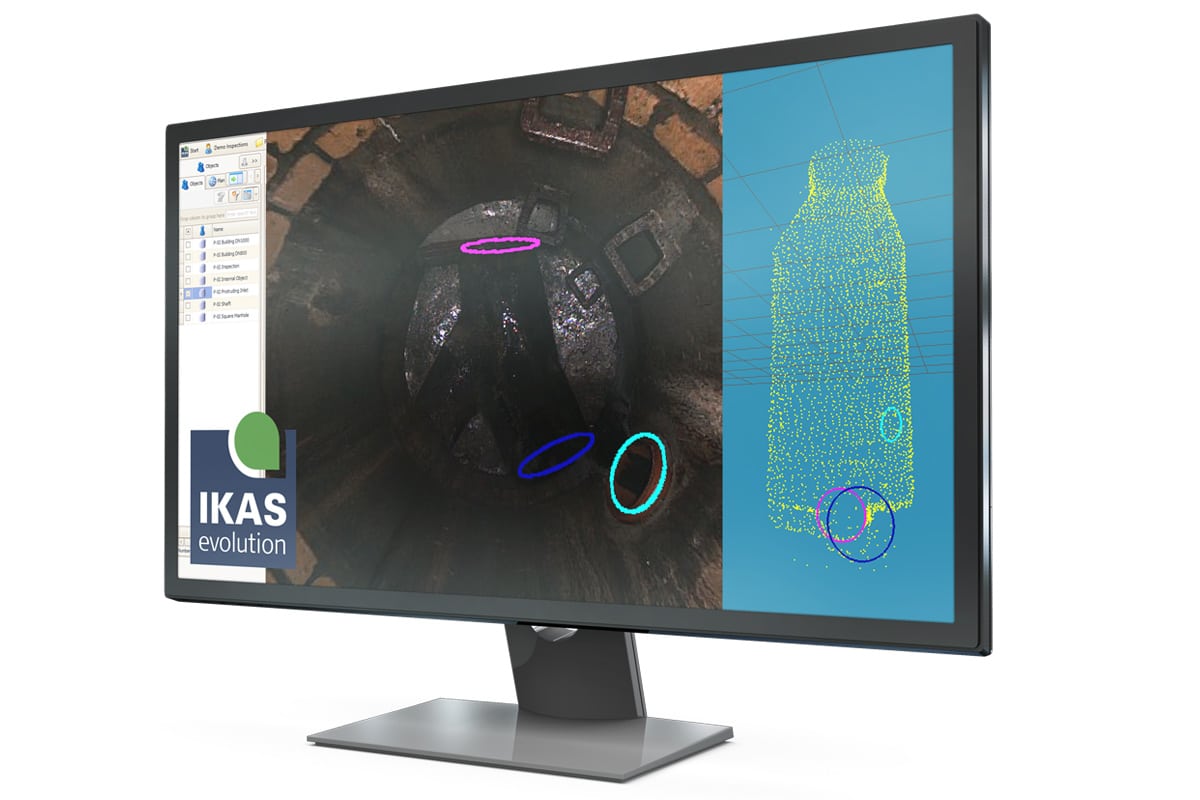

CCTV cameras and 3D scanning systems have transformed the process by capturing detailed imagery and geometric data without requiring manned entry. These modern digital methods enhance crew safety while delivering consistent, repeatable results. Depending on the project, inspection data can include depth, diameter, flow observations, and invert measurements.

In North America, most inspections follow NASSCO’s Manhole Assessment Certification Program (MACP), which provides a common framework for documenting conditions, assigning defects, and ensuring consistency across projects and organizations.

Collecting The Data

Modern manhole inspections gather far more information than just photos or notes. Typically, reports include material type, dimensions, configuration, and details of any structural or surface deterioration. Inspectors record cracks, fractures, corrosion, infiltration, root intrusion, and other defects categorized by severity and location.

Digital inspection tools often capture still images, video, or even 360° panoramic views, creating a permanent visual record of each asset’s condition. This standardized data is vital for asset management and enables engineers and municipalities to prioritize repairs, estimate rehabilitation costs, and document improvements over time.

Without accurate inspection data, rehabilitation efforts risk being inefficient, misdirected, or incomplete.

Part of the Rehabilitation Process

In any manhole rehabilitation process, an inspection is the first step, and arguably the most important step. Before selecting a repair method, engineers must fully understand the extent and cause of deterioration. Inspections reveal whether the structure requires localized repair, full lining, or complete reconstruction.

Insights from manhole inspections also improve coordination with sewer main rehabilitation. By integrating manhole condition data with pipeline inspection results, municipalities can gain a complete view of the entire sewer system’s status. This helps identify where inflow and infiltration (I/I) occur and which structures contribute most to inefficiencies.

Well-documented inspections lead to better rehabilitation outcomes. They ensure that repair strategies are cost-effective and address the root causes of deterioration, extending the structure’s lifespan rather than merely treating surface-level symptoms.

Common Challenges & Best Practices

Like any field activity, manhole inspections can come with challenges. Access can be difficult, particularly in older systems or areas with deep or offset structures. Safety is always a priority when inspecting any confined spaces — traffic control, exposure to hazardous gases, and biological hazards all require strict safety protocols.

Consistency in data collection can be another challenge. Different crews, equipment, or analysis software can produce variations in results. As inspection programs scale up, managing thousands of records from different sources can quickly become complex.

To mitigate these challenges, industry leaders emphasize adherence to MACP standards and proactive inspection schedules. Performing inspections on a planned cycle (before issues arise) helps identify small problems before they escalate into costly failures.

The Future of Manhole Inspection

Manhole inspection technology continues to evolve, reshaping how manholes are inspected, analyzed, and managed. High-resolution 360-degree scanning systems allow crews to capture a complete panoramic view of the structure in seconds. Engineers can then perform virtual inspections from their desktop, zooming in on defects or taking measurements after fieldwork is complete.

Inspection data can be integrated into GIS platforms and asset management software, establishing direct links between field observations and long-term planning. By combining the data from manhole and pipeline scans, users can generate a virtual model of the entire sewer network, enabling them to track changes over time and make informed decisions.

This shift is transforming inspections from one-time observations into data-driven, predictive management tools. As technology advances, inspections will continue to become faster, safer, and more comprehensive, providing a complete picture of the system for better infrastructure planning.

Maximizing Investments

The impact of inspection on system health and rehabilitation success is undeniable. Without a thorough inspection, decision-makers lack the data needed to prioritize repairs and ensure long-term structural integrity.

In an era where municipalities face tight budgets and aging infrastructure, knowledge truly is power. Reliable, standardized manhole inspection data empowers engineers and contractors to make informed, strategic rehabilitation decisions.

By maximizing the return on every dollar invested today, we can lay the groundwork for stronger, more resilient infrastructure tomorrow.

Brandt Eytcheson is a marketing specialist at RapidView LLC.

- Engineered HDPE Solutions for Trenchless & HDD Projects

- Microtunneling Short Course Owner Scholarship Program now Open

- IQuip Introduces the BOOST HDD Support Truck

- How to Maximize HDD Tooling Efficiency in Hard Rock

- Azuria Water Solutions Adds Waterline Renewal Technologies to its Roster

Next Up

2026 CUIIC Academy Spring Summit | March 3-5, 2026 | Mississauga, Ontario | Learn more