Tech Forum – Tips for Lateral Cutter Longevity

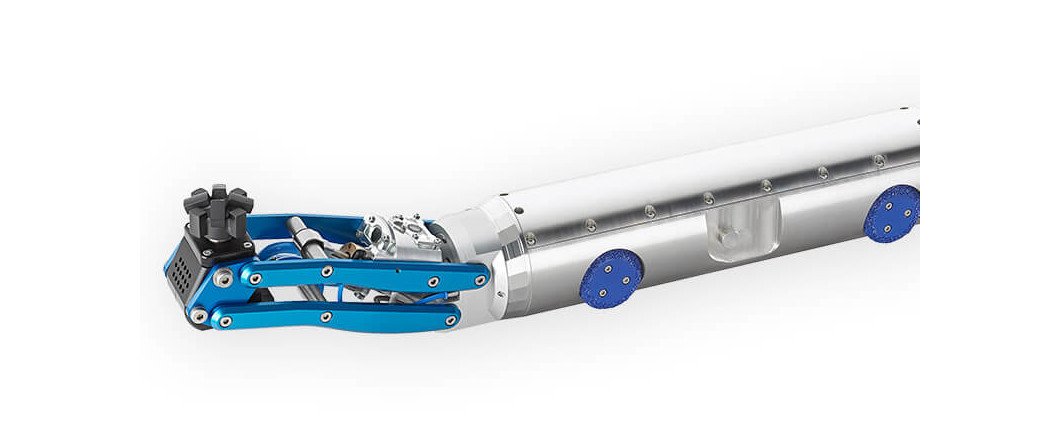

All cutters regardless of manufacturers are based on two concepts: Self-propelled or skid cutter. Today we are focusing on self-propelled as they are more sophisticated, however the same concepts can still be used for skid cutters.

RELATED: Tech Forum – 10 Marketing Ideas to Identify and Attract Trade School Students

To start, a self-propelled cutter uses a drive motor to move the cutter rather than a winch. Similar to a CCTV crawler, these driver motors spin wheels that have bearings protecting a pressurized compartment inside the body of the cutter. If the wheels aren’t rinsed off daily, dirt or resin will build up over time and deteriorate those bearings, resulting in a leak of that pressurized compartment. As a result, water can now migrate in. This same concept is also true for the arms and any rotation point on your cutter. If resin builds up, it will damage whatever seal is built to keep your cutter pressurized.

Keeping the cutter body under pressure is key to protecting the equipment. Losing pressure inside the cutter will be the main way for water to enter the system. As discussed, bearings can wear and become a weak point. Asking your manufacturer what the typical wear parts of the cutter is important because they will teach you when to replace such parts as bearings, seals, or O-rings. By doing this it will keep your system under pressure.

RELATED: Lateral Cutters Serve a Critical Role in the Rehabilitation Process

Aside from your cutter system, your camera may need to be pressurized by itself. This is where nitrogen maybe used. Considering the cutter is being put in a humidity rich environment it is not hard to conceive that condensation can occur. Nitrogen prevents condensation of water within the optics which could reduce visibility or damage the electronic and optical parts within the camera enclosure. Compressed air maybe used however this is where it is important to ask your manufacturer what the best practice is to keep the camera system preserved.

Now that we considered keeping the cutter system pressurized, there are still other parts to consider when using a cutter. The next part that needs to be maintained is the air motor. Air motors use bearings to allow a shaft to spin freely while a series of veins allow air to flow through a channel spinning the motor. This constant spinning creates heat which requires oiling. If the air motor isn’t oiled, the veins will prematurely wear, and the bearings start to breakdown. Consulting on best air motor practices with your manufacturer is important to making the motor last. Also, learning how to use a rebuild kit in case you need to get back up in the field. Electric motors can also be serviced but it is limited without going to the manufacturer.

Past the core parts of the cutter, using a threadlock adhesive can help keep everything together. You would think that tightening a screw will lock it in place but that is not always the case. Vibration, pressure, wear on the threads can all lead to a screw backing out. This isn’t to say Loctite every inch of the cutter but understanding the different types to use and when to use them is crucial if you don’t want something to come lose.

RELATED: Tech Forum – Comparing One-part vs. Two-part Grout for Sewer Repair

Spare parts are also very important to keep on hand. As nice as it would be to have double of everything sometimes that is not the case. However, having spare parts on hand for what you can address is the difference between getting the job done or not. Parts such as termination kits, air motor rebuild kits, O-rings for seals, and screws are easy to keep in-stock for use in a field setting.

Lastly, the right tools are needed for the right job. Identifying the right type of wrenches, hex-key, and hand tools in a convenient layout with a bench is key if you want to do repairs. Beyond that, having a multimeter to test for shorts or confirm continuity in conjunction with the manufacturers training can really help keep your system functioning.

When considering the investment made in a cutter system longevity is key to getting your return on investment. Asking your cutter manufacturer best practices, maintenance tips, and having good communicate will help develop a knowledgeable operator.

Most manufactures even offer in-house training, taking the time out to take advantage of that may seem like a large investment but on a long enough timeline it is the cheapest investment you will make past the cutter. The more the operator knows the better; it will be for the life of your equipment.