Sewer Inspection Supports San Francisco District Tackling Population Growth

Celebrating 75 years of service in 2020, Ironhouse Sanitary District has a rich history in the eastern San Francisco Bay Area. The District, formerly called the Oakley Sanitary District, has been providing service to the community since 1945 — getting its name from a local schoolhouse in 1992.

The District services a population of 44,000 across the City of Oakley and Bethel Island, managing both the region’s water and wastewater departments. The area’s collection systems include 128 miles of gravity pipe ranging from 6 to 30 in. OD, 18 miles of force mains from 4 to 14 in. OD, and 32 pump stations. But that’s only the beginning of the District’s domain — the team also operates a state-of-the-art Water Recycling Facility. This award-winning plant treats upwards of 4 million gallons of recycled water every day.

RELATED: Envirosight ROVVER X SAT II Makes Finding Gas Line Cross Bores in Sewers Faster, More Accurate

Challenge

Over the years, the District has watched small communities turn into incorporated cities, added nearby communities to its own service area, and seen substantial growth across the region. It’s been a lot of change and adaptation, but having a loyal, hardworking team and a tried-and-true workflow has served the District and community well.

“Oakley is one of California’s youngest cities, becoming a city in 1999, and it’s growing immensely,” says Ian Robertson, the District’s CCTV operator. “Currently, we are performing about 25 new construction lateral inspections a month, but some months that number can be as high as 40.”

The area’s steady growth means that the District’s dedicated employees always have their hands full, especially when it comes to reducing sanitary sewer overflows (SSOs) and the negative impact they can have on the environment.

“We follow our sewer system management plan pretty strictly so we can properly manage, operate and maintain all parts of our sewer system and mitigate risks like sanitary sewer overflows,” Robertson notes.

This management plan keeps the wastewater team on track. However, the crew started to feel like their sewer inspection equipment was failing to keep up with the quickening pace.

Solution

The team knew it was necessary to make a significant change or risk falling behind, especially as population levels in the Bay Area continued to increase.

“In the fall of 2019 we decided to start looking into more efficient sewer inspection equipment to keep up with the growing demand,” Robertson says.

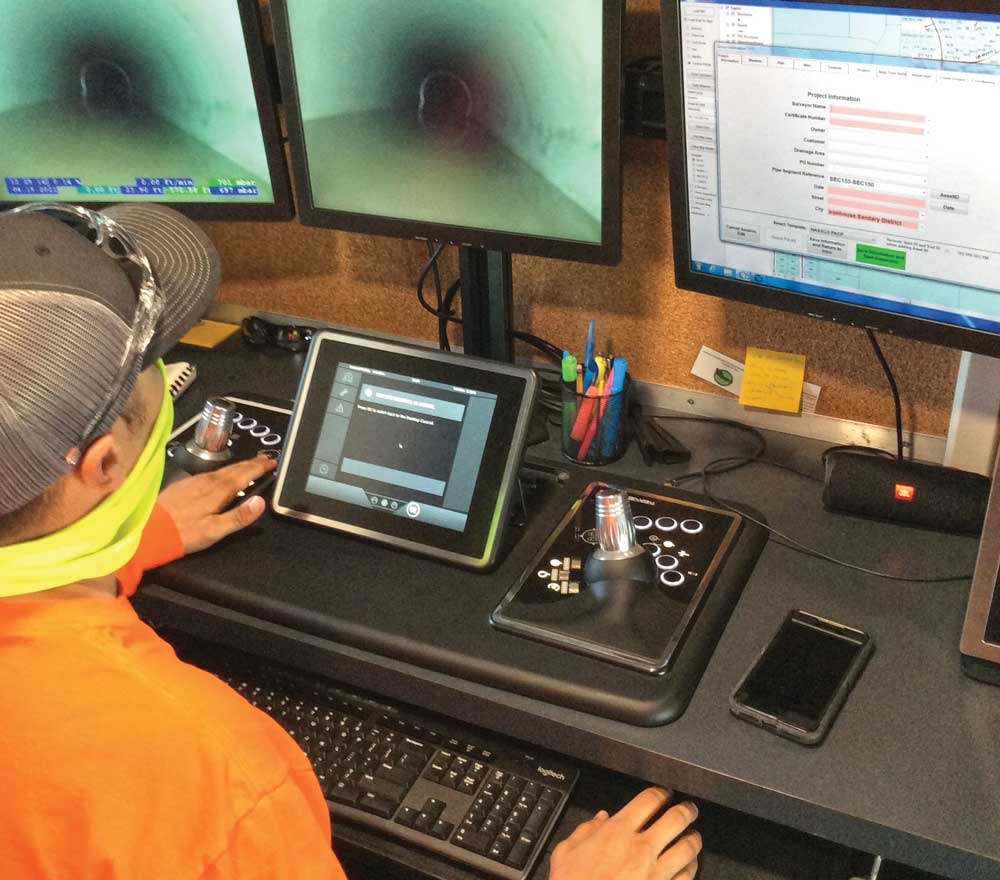

The crew’s search led them to U-Rock Utility Equipment, Envirosight’s sales partner in Northern California. The U-Rock team demonstrated a ROVVER X sewer inspection crawler system to the District. Robertson notes that he was particularly impressed with the inspection vehicle housing the crawler equipment.

“The process was absolutely amazing,” Robertson says. “I got in the truck and within one hour I felt really comfortable operating it by myself.”

The District now owns a custom-built inspection truck based on a Ford E-450 chassis and equipped with the ROVVER X crawler system, the ROVVER X SAT lateral launch crawler, and the RX95 small-diameter crawler.

RELATED: Scanning Offers In-depth Look at Manhole Condition

Sewer Inspection Results

It didn’t take long after investing in the new gear for the team to notice a difference in their inspection capabilities.

“This truck compared to what we were using, it’s just night and day,” Robertson says. “Previously, we needed tools to take apart the camera — to change the wheels or change the setup. What would take at least 10 minutes to change before, takes less than two now. It’s definitely made things easier for us. I absolutely love it.”

The team experienced a higher degree of accuracy when it came to lateral inspections using the ROVVER X SAT lateral launch system.

“The SAT system has been great for inspecting for I&I when needed,” he added. “It’s very convenient to have the sonde when you launch the lateral. You can just walk right up to it, you know where it is, you’re confident in your mark, and we absolutely love that.”

The small-diameter crawler has also come in handy in pipe sections where a standard crawler body size wouldn’t fit, he says.

“We have 6-in. ductile iron pipe in some places and it gets a bit corroded,” Robertson says. “Even after cleaning it you can’t fit a six-inch camera setup through, so we put that little guy in there and it’s absolutely amazing the work that it does for us.”

Since upgrading its inspection truck and cameras, the District has seen a big boost in productivity — which is crucial for a department expecting continuous growth in the coming years.

“We have definitely been able to work more productively with the Envirosight setup,” Robertson says. “It takes 30 seconds to change wheels, it takes a minute to put the elevator system on, the camera is so much cleaner, the lens doesn’t get as foggy, and the video is clearer. Everything is just 100 percent better with this truck.

“We do a lot of mainline inspections with the ROVVER X and it lets us survey lines with ease. Connecting the elevator lift to inspect trunk lines is just so simple and convenient. With that crawler, if there is gravel in the way or something, it will run right over it no problem.”

And the local support from U-Rock Utility has been a great bonus, too, he says.

“When we needed camera service, Mark Paduveris showed up the very next day to pick it up, have it repaired, and returned it within a couple of days,” Robertson says. “That’s been a great benefit and has really helped us avoid downtime.”