Sanitary Sewer Evaluation Surveys: Why and How – Part I

Out of sight, out of mind” has all too often become the mindset when it comesto dealing with our sanitary sewer system. As a case in point, the AmericanSociety of Civil Engineers (ASCE) “Infrastructure Report Card 2005”

Out of sight, out of mind” has all too often become the mindset when it comesto dealing with our sanitary sewer system. As a case in point, the AmericanSociety of Civil Engineers (ASCE) “Infrastructure Report Card 2005”

(http://www.asce.org/reportcard/2005/index.cfm) awarded the U.S wastewaterinfrastructure a grade D- — the lowest of all grades issued.

The U.S.Environmental Protection Agency (EPA) estimated in August 2004 that sanitarysewer overflows (SSOs) result in the release of as much as 10 billion gal of rawsewage annually. Federal funding under the Clean Water Act State Revolving LoanFund (SRF) program has remained flat for the past decade. With one exception,Congress appropriated between $1.2 and $1.35 billion from 1995 to 2004. But inFY 2005, Congress cut wastewater SRF funding for the first time in eight years,reducing the total investment to $1.1 billion. The current administration hasproposed further cuts for FY 2006, with a budget submittal calling for anappropriation of only $730 million, a reduction of 33 percent from the FY2005-enacted level.

With shrinking budgets and continued deterioration ofour aging systems, there are compelling reasons to support a pro-active andintelligent approach to sanitary sewer evaluation and management (SSEM). Thisarticle highlights how owners and engineers might proceed with collectingattribute information associated with their collection system, identifyingpotential problems within the system, determining capacity issues and ultimatelydevelop effective maintenance and rehabilitation strategies to mitigate theseproblems in a cost-effective manner.

Why

A sewer system evaluation survey(SSES) is the critical first step in a SSEM program that includes projectmanagement and coordination of flow monitoring, sewer system evaluation, fieldsurvey, system mapping, hydraulic modeling and analysis, best managementpractices, cleaning and long-term maintenance management programs. Most localagencies have laws or ordinances that require all publicly and privately ownedand operated sanitary sewer collection and transmission systems to complete aSSES by a stipulated time. In many cases, the SSES is conducted in compliancewith guidelines based on EPA’s Sewer System Infrastructure Analysis andRehabilitation Handbook (October 1991, EPA/625/6-91/030).

In addition,recent EPA regulations such as capacity, management, operations and maintenance(CMOM) are requiring some publicly owned treatment works (POTWs) to reduce andeliminate sanitary sewer overflows and bring the handling of domestic wastewaterinto compliance with national pollutant discharge elimination system (NPDES)permits by 2011.

By directing their sewer system self-audits into a SSEMprogram, owners of POTWs can satisfy EPA requirements, cure SSOs, consolidateexisting information, modernize facilities and focus on their CMOM program. Thefollowing are some examples of SSES programs under way or recentlycompleted.

City of Atlanta

The City of Atlanta’sDepartment of Watershed Management is currently conducting a comprehensivesanitary sewer evaluation as a part of its Clean Water Atlanta program — amulti-billion dollar initiative encompassing sanitary sewer rehabilitation,repair and enhancement.

The SSES program uses various equipment andtechniques to detect pipe defects, blockages and capacity issues. The techniquesinclude smoke tests, dye tests, closed circuit televising (CCTV), flowmonitoring, rain monitoring, building of service connection location/inspectionand flow isolation.

The sewers are grouped into drainage basins. Theevaluation of Sewer Group 1 was completed in March 2004 and work on Sewer Group2 commenced in late 2004. According to the final report from Sewer Group 1, 316miles of sewer were inspected using CCTV and smoke testing, 146 miles of sewerwere cleaned, 7,349 manholes were inspected, 761 manholes were raised and 119emergency repairs were completed.

City ofColumbus, Ohio

A large SSES project was accomplished for theDepartment of Utilities, Division of Sewer and Drains (DOSD) in Columbus, Ohio,in the period from August 1997 to December 1999.

Overall, the SSESinvestigation included: the inspection of 1,184 manholes; smoke testing of267,162 ft of sanitary sewer; 38,912 lf of CCTV inspection; 32 dye tests; seventemporary flow meters; 10 groundwater piezometers; and four raingauges.

Miami Dade County,Fla.

Since 1994, the Miami-Dade Water and Sewer Department (WASD) hasengaged in an extensive sanitary sewer system evaluation and rehabilitationprogram in an effort to reduce system infiltration, exfiltration and inflow(I/E/I).

Under the I/E/I Program, the entire sanitary sewer collectionsystem, which represents approximately 12.9 million ft of gravity sewer linesand 58,000 manholes, was evaluated by July 1997. The sewer evaluation consistedof cleaning and televising 100 percent of the gravity lines, the visualinspection of each manhole and the smoke testing of the entire system toidentify defects. A total of 32,194 defects were identified and repaired. TheI/E/I Program has been highly successful with system flows to the regionaltreatment facilities reduced by approximately 100 mgd. Although the system-wideinfiltration was greatly reduced, rainfall dependent infiltration/inflow (RDII)and the various pump station force main improvements have continued to increasethe peak flows to the treatment facilities during heavy rainfall.

How

SSES is a comprehensive andsystematic process aimed at identifying and investigating sanitary sewer systemproblems (e.g. inflow/infiltration sources and structural deficiencies) anddeveloping maintenance and rehabilitation methods to solve these problems.During the survey, the system is thoroughly inspected and data about thecondition of various system components are collected. The main fieldinvestigative procedures typically include:

• Flow Monitoring

• SmokeTesting

• Manhole Inspections

• Dyed Water Testing

• CCTVInspection/Sewer Scanning

With shrinking budgets and continueddeterioration of our aging systems, there are compelling reasons to support apro-active and intelligent approach to the SSEM program. The following steps arerecommended in a comprehensive SSES program for owners andengineers.

History

The first step inunderstanding a municipality’s collection system is to obtain information fromits employees. Many long-term employees have an institutional memory that isoften missing from official records. While this step appears obvious, it is fartoo often ignored, which can be detrimental to the program. The information canbe obtained through interviews or questionnaires from employees from anydivision that has an understanding of where problems have been occurring withinthe system. In addition, it is important to review the history of customercomplaints.

Both of these pieces of information provide immediatefeedback on the location and magnitude of potential problems. During thequestion phase, information pertaining to existing maintenance procedures shouldbe collected. Personnel responsible for these tasks should be asked to providerecommendations for changes within the current maintenance program.

Mapping

During the interview, process maps arecommonly used to identify problematic locations. Having detailed maps isimperative to setting up any type of proactive evaluation program. The mapbecomes the way to properly track what comprises the system and where and howthe system changes over time. The advent of satellite systems and technology,such as global positioning systems (GPS), provides the ability to obtainaccurate locations of manholes, pump stations, etc., with the click of abutton.

Furthermore, this information can be stored in geographicinformation systems (GIS) so as to have access to specific information regardingany attribute information associated with the collection system. Placing thisinformation in such a system allows more precise data to be stored, enabling anyinterested party to understand the makeup and condition of the sewer system.

Flow Monitoring

Locations of possiblecapacity issues can be identified by tracking SSOs and reported basement backupsor through temporary flow monitoring. Temporary flow monitoring is usually oneof the first actions taken to better understand the problematic areas within acollection system. It may also be performed to verify the success ofrehabilitation projects associated with inflow/infiltration (I/I) removal.Rehabilitation success verification is performed by comparing pre- andpost-rehabilitation flows in a project area, as well as using a control basinthat has not been rehabilitated.

Temporary flow monitoring studiesgenerally last 60 to 120 days and are performed during a community’s wet season.Electronic velocity and depth recording devices (flow meters) are strategicallyplaced (usually in the upstream pipe entering a manhole) throughout thecollection system. Typically each meter might be responsible for monitoring flowfrom 20,000 to 30,000 lf of tributary sewer. The purpose of installing flowmeters is to determine the quantity of flow at a particular location during bothdry and wet weather conditions. Sewers having high dry weather flows typicallyhave little capacity for future connections. Drainage areas that experience highwet weather peaking factors are typically scheduled for more detailedinspections. Peaking factors in excess of five times dry weather flows aregenerally considered to have excessive wet weather flow.

Once theinitial site selection for meter placement has been made, flow-monitoringpersonnel should visit the location to determine if the site will provide gooddata. The preliminary site inspection is performed to verify that the selectedlocation has good hydraulic conditions, there is easy access and to determine ifit is safe to physically enter the manhole. If any of these qualifications arenot met and the flow characteristics are not compromised by relocating themeter, an alternative site should be selected. Generally, a suitable replacementsite can be found within one or two manholes upstream or downstream of theoriginal site.

During a preliminary inspection, an accurate measurementof the pipe size is made, as well as the recommendation of the best type of flowmeter to collect the information. As noted previously, flow meters record depthand velocity, but some meters are designed to perform better in differentenvironments. The following matrix identifies some of the more prominent flowmonitoring technologies and the flow parameters:

FlowDepths (in.) | Flow Velocities (feet/sec) | Equipment |

|---|---|---|

1.5 – 36 in. | 0.5 fps – 5 fps | ADS, Sigma 900 series, ISCO 2000 series |

>12 in. | 0.5 fps – 5 fps | MGD |

Low | > 1 fps – 1.5 fps | Marsh McBirney Flow-Dar |

It should be noted that for many years redundant depth measurements were takenwith ultrasonic equipment to verify flow depths. This was done because pressuretransducers had a tendency to drift, resulting in inaccurate depth readings.However, over the last three or four years, the Sigma and ISCO pressuretransducers have become much more stable and reduced the need for the ultrasonicreadings.

Once the site and proper meter have been selected, the time period betweenrecording intervals needs to be determined. Flow meters are typically in ahibernation mode. They remain in the line/manhole and at established intervalsthe meter activates and measures depth and velocity. The most common timeframebetween meter readings is 15 minutes. However, if the meter is in the vicinityof a pump station this duration may be reduced to five minutes. By reducing thetimeframe between readings, the meter is more likely to capture the flowsassociated with the pump cycling on and off. Measurements are stored internallyin the meter until either maintenance personnel collect the data using laptopcomputers or the information is transmitted wirelessly to its desired location.

During the installation process, pictures should be taken of the sensor after itis installed in the pipe and an opening site sheet should be completed. Thepreferred location of the sensor (typically mounted on a steel band) is in theinvert of the upstream line coming into a manhole (see Figure 1). The openingsite sheet describes the meter setup, provides a small sketch of the meter’slocation within the sewer system and the sensor’s placement within the manhole.Immediately after, meter installation manual measurements of the flow’s depthand velocity are taken and compared to the readings from the flowmonitor.

During the installation process, pictures should be taken of the sensor after itis installed in the pipe and an opening site sheet should be completed. Thepreferred location of the sensor (typically mounted on a steel band) is in theinvert of the upstream line coming into a manhole (see Figure 1). The openingsite sheet describes the meter setup, provides a small sketch of the meter’slocation within the sewer system and the sensor’s placement within the manhole.Immediately after, meter installation manual measurements of the flow’s depthand velocity are taken and compared to the readings from the flowmonitor.

Once meters are installed, maintenance crews should service themon a weekly basis to ensure that they are operating properly. Service shouldinclude checking the battery voltage, checking the desiccant crystals (whichhelps keep moisture out of the meter), cleaning the sensor and comparingreal-time level and velocity readings from the flow meter to readings physicallymeasured by maintenance personnel. If these readings differ substantially, themeter should be replaced. Field crews should document the time and allinformation collected during their maintenance visits.

The reviewershould evaluate the data from both a weekly perspective, as well as how the mostrecent data compares with data previously collected. This quick review will helpminimize the potential for the collection of inaccurate data as a result of amalfunctioning meter. After the review is completed, any potential problems,concerns or directives should be transmitted back to the maintenance crew.Continual communication between the reviewers and the maintenance crews iscritical to successfully completing a flow-monitoring project.

Raingauges are typically installed in conjunction with flow-monitoring projects.These instruments should be capable of measuring rainfall in 0.01-in.increments. Rain gauges are generally comprised of a tipping bucket mechanismand a data logger. Both the flow monitor and rain gauge data should havecorresponding date and time information, so as to compare rainfall events withflow readings. Rainfall data enables engineers to model a sewer’s hydraulicresponse during different rain occurrences.

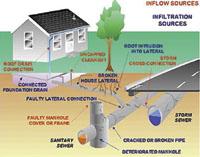

During rain events, sanitary sewer flows tend to increase as a resultof either inflow or infiltration. Inflow is defined as rainwater that can entera sewer system directly, while infiltration percolates through the ground andthen enters a sewer. (See Figure 3 for typical sources of I/I.)

Inflowcharacteristically causes rapid increases in a sewer’s flow and results in seweroverflows and or basement backups. Inflow usually recedes within four to fivehours after the completion of a rain storm, while infiltration is associatedwith slower increases in flow and might take as long as four or five days todissipate. When peak instantaneous flows increase in a sanitary sewer system bymore than a factor of five, it is recommended to schedule more inspectionactivities in that basin. Since inflow usually creates more capacity problems —resulting in overflows — municipalities and engineers typically address thisproblem first. The two most common forms of inspection associated with locatinginflow are smoke testing and manhole inspections. Each of these procedures canidentify sources of inflow and assist in the development or correction of amunicipality’s mapping.

Manhole inspections are typically started in theupper reaches of the problematic basin. If at all possible, manhole inspectionsshould be performed during the rainy season. Performing this task during wetperiods helps to identify I/I that might not be discovered during the dryseason. The data collected during this process helps to:

• Identify sourcesof I/I

• Determine structural condition of the manhole and sewersegments

• Locate and categorize structural defects

• Provide size andconstruction material of both the manhole and sewers

• Determine a sewer’sinvert depth from the top of the casting

• Verify the presence of surchargingand blockages

• Verify approximate location of manhole

• Identify futuretelevision inspection locations

In low traffic areas typically atwo-person inspection crew can perform an inspection. The crew should beequipped with a truck, protective clothing, lights, digital camera, various handtools and other equipment necessary to conduct safe and thorough confined spaceinvestigations. Manhole entries are generally only made on manholes greater than10 ft in depth (field crews can typically see all the needed information fromthe ground on manholes less than 11 ft). If entry is required, it must beaccomplished in accordance with all OSHA, federal and/or local laws, regulationsand/or guidelines for confined space entry.

The following procedurescomprise the manhole inspection sequence:

• Erect proper traffic controlmeasures

• Open manhole

• Inspect manhole frame and lid

• Descend intomanhole (if greater than 10 ft deep), determine the type of constructionmaterial, evaluate the structural condition of the manhole and sewers anddetermine the sizes of all pertinent structures

• Digitally photograph anyidentified structural defects

• Measure depth of inverts from topcasting

• Replace manhole lids and remove traffic control

Planimetric sewer system information collected by the field inspectors shouldbe checked against existing mapping. Any discrepancies should be marked on themapping by the field inspectors and sent to the owner or owner’s representativefor correction.

Before entering the manhole (if greater than 10 ftdeep), the field inspector should evaluate both the manhole lid and framecondition, and the frame connection to the manhole prior to entry. As theinspector descends into the manhole the manhole cone, barrel, trough, apron andsewer line are evaluated. Digital photographs should be taken of all manholedefects, any sources of inflow/infiltration as well as the influent and effluentlines. All of this information, including photos of any defects, should becollected in such a way to be imported into a municipalities GIS system.Pictures should also be taken in the upstream and downstream sewers and utilizedto recommend locations for television/scanning inspections.

Television/scanning inspections are typically recommended whensignificant roots, cracked pipe, slipped joints, grease, or evidence ofsurcharging is observed.

Smoke testing is an inexpensive technique toidentify sources of I/I and improper connections to the collection system.Problems commonly identified include: storm sewer cross connections and pointsource inflow leaks in drainage paths or ponding areas, roof downspouts, yardand area drains, foundation drains, abandoned building sewers, faulty sewerconnections, or broken clean out caps. Smoke can also escape from defects in thepipe, which are above the water table (infiltration), but the smoke must find apath to the surface in order to be observed. Smoke emerging from the ground,streets, sidewalks, etc. indicates a pipe defect, but does not indicate theexact location of the defect.

Smoke testing should only be performed whenthe ground is dry. Testing should be closely monitored on windy days. If thesmoke coming out of the ground is blown away so quickly as to escapebefore itcan be accurately detection detected by the field crew, testing needs to ceaseuntil such time thosewind and soil conditions permitted favorable testing andresult documentation.

Prior to beginning smoke testing, colorednotification flyers should be placed on all residential and business locationsexplaining that smoke testing would will be occurring in the area during thenext few days. The notice should include the a phone number that the occupantcan call might need to have theirany questions answered. Additionally, eachmorning before smoke testing begins, field crews should contacted theappropriate fire department, other potential emergency respondents and themunicipality’ies customer service center, to report where smoke testingactivities would will be occurring for that day. Maintaining good communicationswith all these different groups will help to minimize the confusion that canoccur when people see smoke coming from unusual locations that it is notnormally seen.

Smoke, is typically generated using liquid smokecanisters, andis forced ventilation through the sewer system using gasolinepowered smoke blowers. Smoke blowers having a capacity to generate at least 3000cubic feet per minute is preferred. Typically, two or three stretchessections ofsewer can be tested at each set up (700-900 LF). As the smoke is being pushedblown through the pipe, field inspectors walk around and document any observedleak on a smoke test form. Digital pictures should also be taken of allsubstantial leaks. Leaks should be referenced by distances from at least twopermanent locations. One way to do this is tothis is done is by measuringe adistance from one of the manholes along the sewer line that is leaking and thenalso measuring the perpendicular distance, left or right, perpendicular to thesewer line adjacent to from the leak. It is also common to reference leaks frombuilding corners or trees.

The information collected from smoke testing can often find sources thatcontribute large sources of inflow, such as cross-connected storm grates ordownspouts. It can also lead to recommendations for additional fieldinspections.