Rehabilitating the Herridge Feedermain Using CFRP Techniques

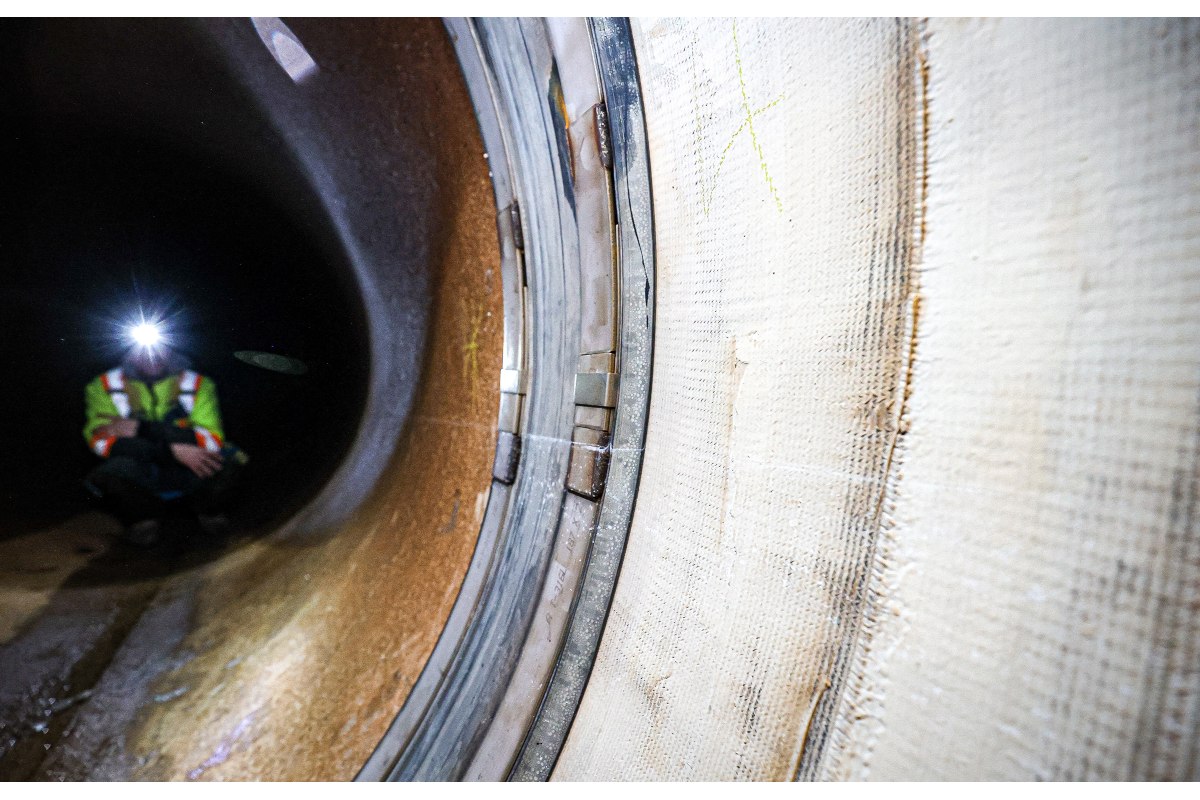

The Herridge Feedermain, a critical water pipeline in the Region of Peel (in Mississauga, Ontario), has undergone a significant renewal. It used carbon fiber reinforced polymer (CFRP) techniques.

The Region of Peel has brought innovative thinking to their infrastructure needs. They adopted out-of-the-box techniques surrounding their renewal process. This included design considerations, environmental requirements, and long-term performance requirements of the CFRP liner.

The Herridge Feedermain, constructed in the late 1970s, is a 1,500-mm inside diameter prestressed concrete cylinder pipe (PCCP). It spans approximately 6 km and operates under a maximum working pressure of 150 psi.

In 2011, the Feedermain was taken out of service due to significant distress in many of the pipe segments. Peel investigated several innovative rehabilitation options. They opted for CFRP renewal techniques, as excavation was impractical due to the pipeline’s location under roads and highways with heavy traffic.

Renewal Begins

The renewal process began in early 2016, targeting 106 pipe segments. CFRP products, known for their high strength-to-weight ratio, are three to five times stronger than steel and supersede most structural materials.

The CFRP solution was chosen because it is lightweight, corrosion-resistant, and durable. This made it ideal for confined spaces and this project. The renewal process adhered to environmental requirements, ensuring all components were ANSI/NSF 61 certified for potable water applications. The CFRP liner design followed the AWWA C305-24 standard.

CFRP Selection

Two types of CFRP liners were used:

- Stand-Alone CFRP Liner, where the pipe is assumed to be fully deteriorated and the CFRP liner sustains all applied loads.

- Composite CFRP Liner, where the pipe is partially deteriorated. The CFRP liner and PCCP inner core are designed as a composite section to sustain the applied loads.

The CFRP products used in the renewal of the Herridge Feedermain had to comply with several performance requirements. These ensured durability and safety. The requirements included:

- Durability Compliance: CFRP products must comply with the durability requirements as per Table 1 of AWWA C305-24.

- ANSI/NSF 61 Certification: In potable water applications, all components of the CFRP repair material must be ANSI/NSF 61 certified.

- Thickness Limitations: Adhere to limitations on the maximum thickness of the CFRP liner for pipes and tanks.

- Environmental Conditions: Meet all environmental conditions as prescribed by the manufacturer. This included air and surface temperature, humidity, dew point temperature, and the substrate surface condition.

These requirements ensured that the CFRP liner would perform effectively under various environmental conditions and maintain its integrity over time.

Project Phases

Two types of CFRP liners were used as described above. The Stand-Alone CFRP Liner sustains all applied loads, both internal and external. The Composite CFRP Liner, in contrast, has the CFRP liner and the PCCP inner core designed as a composite section to sustain the applied loads. For axial thrust, the Stand-Alone CFRP liner design was always used. The design also considered accessibility for repair and confined space issues.

Reviewing the Herridge Feedermain Project

| Phase I | 2016 Phase I utilized bi-directional fibers (uni-directional fibers that are pre-stitched into bi-directional layers) for CFRP lining. This renewed 106 pipe segments. Despite some buckling failures in composite pipe segments, the CFRP liner proved effective in strengthening and renewing the PCCP. |

| Phase II | 2022 Phase II continued with bi-directional fiber design, renewing 24 pipe segments. Long-term exposure tests showed that the CFRP liner met and exceeded AWWA C305-18 requirements. It endured more than 40,000 hours of exposure to pressurized water. |

The long-term tensile strength and modulus of the CFRP liner were investigated after five years of exposure to potable water in a pressurized feedermain. They were found to meet/exceed AWWA C305-24 requirements. The Herridge Feedermain is scheduled for a 10-year warranty inspection in 2027.

The CFRP renewal of the Herridge Feedermain has provided valuable insights. This includes the effectiveness and challenges of using CFRP techniques for pipeline repair and renewal. The project demonstrated that CFRP liners are a viable solution for strengthening and renewing distressed PCCP. It ensured a reliable water supply for Peel.

“Peel has always embraced innovation in their approach to infrastructure renewal and construction. Introducing CFRP into our organization has proven to be an effective solution. It has the flexibility Peel needed to address the rehabilitation of this major pipeline,” says Anthony Parente, general manager of Water and Wastewater, Region of Peel. “The success of this project has led to Peel adopting CFRP in a number of our large renewal projects in both water and wastewater.”

The successful renewal of the Herridge Feedermain demonstrates the effectiveness of CFRP techniques. It helps in maintaining and enhancing critical infrastructure, ensuring a reliable water supply for the Region.

Project Outcomes

Effectiveness of CFRP Liners

The CFRP liner proved to be an effective repair technique for strengthening and renewing PCCP. The liner met and exceeded AWWA C305-24 requirements after more than 40,000 hours of exposure to pressurized water.

Regulatory Compliance

The CFRP products used in the renewal process adhered to regulatory requirements, ensuring durability and safety in potable water applications.

Design Standards

The CFRP liner design followed the AWWA C305-24 standard, utilizing both Stand-Alone and Composite CFRP liners to sustain applied loads.

Water Tightness

Water tightness testing revealed that the CFRP liner maintained its integrity under high pressure. This included areas with termination joints and overlaps.

Long-Term Exposure

The long-term tensile strength and modulus of the CFRP liner were investigated after five years of exposure to potable water. They were found to meet/exceed AWWA C305-18 requirements.

Water Tightness Testing

Water tightness testing under tensile stresses revealed the need for adequate overlap. This maintained the integrity of the CFRP pipe at high pressure.

Collaboration

CFRP suppliers and installers were encouraged to cooperate with project owners. They should leave CFRP sheet samples inside watermains for long-term exposure and further testing over the service life of the watermain.

Flexibility

The ability to apply CFRP in sections as either Stand-Alone or Composite provided design flexibility. This is contrasted with alternative solutions requiring a single thickness for the full length of the pipe.

Khaled Hassan, PhD, P. Eng, is a senior structural engineer at Ark Structural Engineering. Terry Martins, P. Eng is president, TCI Carbon Fibre Technologies.

Latest Posts

- Azuria Water Solutions Adds Waterline Renewal Technologies to its Roster

- Puris, Per Aarsleff Partner to Strengthen Lateral Rehab in Canada

- Vortex Companies Rebrands Grout Line to Maverick Grouts

- Vermeer Unveils VXT400, VXT500 Vacuum Excavators

- How to Reestablish Service Connections After In-Building CIPP Rehab