Quick-Lock – Made in USA

The Original stainless-steel sleeve with over 30 years in field experience made a strong move forward.

On January 7, 2026, it became a reality. The first Quick-Lock sleeves rolled off the production line. Our new production site in Chambersburg, PA, began operations.

Where simplicity meets economic efficiency

For more than 30 years, countless users and clients worldwide have sworn by the repair systems from Uhrig Kanaltechnik. The Quick-Lock (QL) system has also been used successfully in the USA for around 20 years. The stainless-steel sleeve system complies with ASTM regulations and has approvals for example, from the FDOT and MnDOT, the NSF, the WRc, DIBt and other approvals that are in demand worldwide.

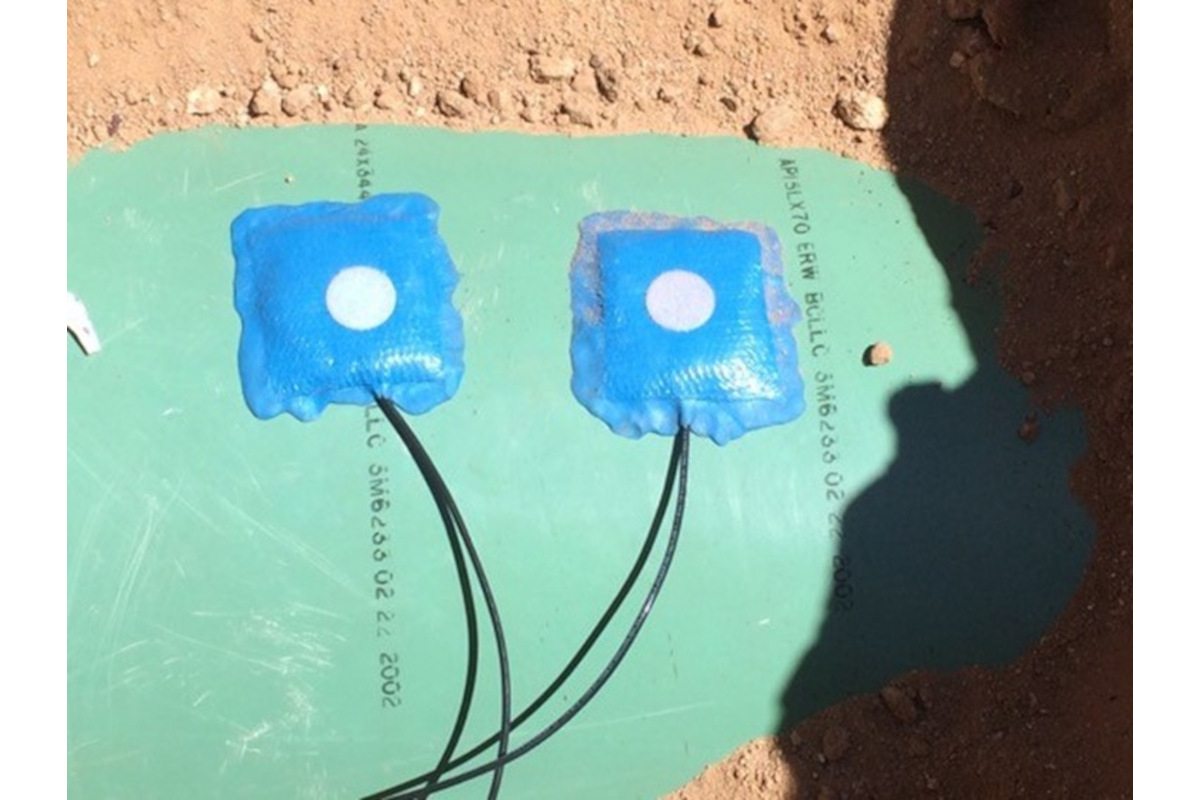

Quick-Lock systems are literally the “heart stent surgery” of system-relevant infrastructure. These systems are installed in everything from sewage and stormwater pipes to drinking water pipes. Well renovations and industrial pipes (LD and HD) complete the range of applications. Steel grades 319L and 904L for pipes exposed to seawater and three different seals (EPDM, NBR, and silicone) round off the sleeve technology range. Corresponding setting packers for point repair and setting bladders and cutting tools for LinerEnd sleeves, as well as setting tools for manual installation for the BIG range, support the professional use of Quick-Lock systems.

From small to BIG

With nominal diameters ranging from NPS 3.9” to NPS 118”, there are virtually no limits.

• QL STANDARD for interior pipe diameters NPS 3.9” – NPS 32” as a single sleeve version (point repair and serial installation is possible)

• QL LinerEnd connections from NPS 3.9” – NPS 32” single sleeve version

• QL BIG from NPS 32” – NPS 118” in 2-, 3- or 4-part system

• QL BIG LinerEnd from NPS 28” – NPS 94” in 2- and 3-part system

• QL PRESSURE PIPE LD (low duty) and HD (high duty)

from NPS 6” – NPS 32”

• QL PRESSURE PIPE LD and HD from NPS 6” – NPS 24”

A purely mechanical point repair system, that can be installed with limited manpower in a matter of minutes with any CCTV crawler. It does not require any construction chemicals and can therefore be used regardless of weather conditions.

Area of application:

• Leaks (groundwater infiltration and exfiltration)

• Cracks (longitudinal, radial and transverse)

• Fragmentation

• Leaking joints

• Displacement / offsets

• Root penetration

• Closing / sealing unused laterals

• Corrosion / spalling / wear

• Improving the structual strength of pipes

• LinerEnd connections

• Manhole joint repair / entry connection

Success through partnership

Sustained growth cannot be achieved alone. Thanks to our certified partners in the USA, who are primarily responsible for the distribution of Quick-Lock systems, sales have increased steadily in recent years. Various sub-dealer networks of our certified partners have played a key role in this success. Cities, municipalities, and industrial companies are enthusiastic users of Quick-Lock.

Learn more about the variety of systems and visit us at our booths.

WWETT Show: Expo Hall booth number 3400 and at the German Pavilion 4228

(You can also find Quick-Lock at the following stands at WWETT: Rausch Electronics USA LLC 1625; PRT – Pipeline Renewal Technologies 6249; Trenchless Supply Inc. 2504)

NASTT NoDig in Palm Springs from March 29 to April 2, booth number 272