Challenging Trunk Sewer Condition Assessment and Rehabilitation Initiatives in the Region of Peel

In response to its aging infrastructure, the Region of Peel has taken the initiative to establish a comprehensive asset management program, which includes sanitary sewer pipe assessment and renewal.

The regional municipality is in the Greater Toronto Area (GTA) and has a sanitary sewage collection system that services a population of about 1.4 million across the cities of Mississauga and Brampton, and the Town of Caledon.

The collection system is owned and operated by the Region and classified by the Ministry of the Environment, Conservation and Parks (MECP) as a Class III Wastewater Collection Facility, under Ontario Regulation 129/04.

The considerable collection system is comprised of 3,659 km of sewer pipes, 50 km of forcemains, 55,995 maintenance holes, and 33 pumping stations as of 2020, with more scheduled to be designed and constructed in the coming years – but the overall infrastructure of the Region is aging and requires more investment in preventative and planned maintenance.

“We wanted to ensure we had inspected, or had plans in place to inspect, all sanitary trunk sewer assets to get a handle on their current condition,” says Nicholas Gan, P.Eng., PMP and manager, engineering of the Region of Peel’s Condition Assessment and Rehabilitation (CA&R) Group. The program is part of an ongoing plan of upgrading the Region’s sanitary sewer system to ensure long-term integrity and sustainability.

Part of this plan includes the creation of Gan’s CA&R Group, which oversees the assessment, repair or rehabilitation of existing trunk sewers and transmission watermains to improve hydraulics, minimize potential for spills and overflows to the environment, minimize the risk of backups into homes, help ensure continuity of service, and upsize if required to meet future planning needs; all to provide a higher-level of service to the Region’s growing population.

The first official rehabilitation project undertaken by the CA&R Group is the recently completed Fletcher’s Creek Trunk Sewer Rehabilitation project. The sewer is in the City of Brampton and while the first 13 upstream sewer segments are located on-road, about three-quarters of the sewer runs through the valley area in proximity of Fletcher’s Creek within the Credit Valley Conservation regulated areas.

Robinson Consultants Inc. was retained by the Region to complete the condition assessment, detailed design, contract administration, and inspection for the rehabilitation of the Fletcher’s Creek Trunk Sewer in 2019.

“We were very excited to partner with the Region of Peel’s CA&R Group on this significant first project and assist the Region in achieving their long-term rehabilitation objectives,” says Robinson Consultants’ project manager and technical lead Kevin Bainbridge, C.E.T.

The project scope included the rehabilitation of 41 trunk sewer segments, which worked out to approximately 4 km of 750 mm, 975 mm, and 1,200 mm diameter segments at an average depth of 8 to 12 m. The total length of rehabilitation by cured-in-place pipe (CIPP) was 2,385.2 m, with a longest single CIPP shot of 335.2 m in length.

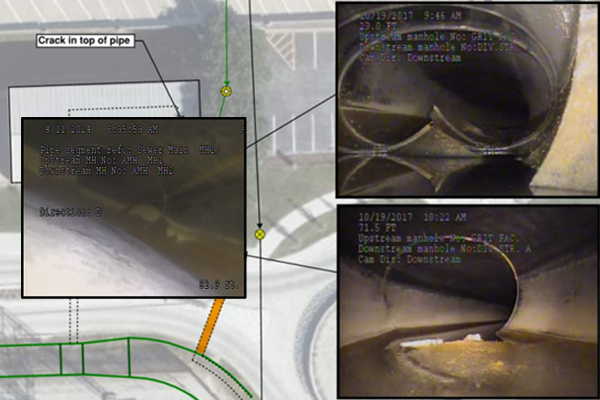

The project also included 31 mechanical seals and the rehabilitation of 42 maintenance holes ranging from 1,500 mm, 1,800 mm and 2,400 mm in diameter at an average depth of 8 to 12 m. The condition assessments previously conducted by the Region revealed that several sections were in poor condition, with longitudinal fractures and heavy infiltration. The goals of the project were to restore structural integrity, eliminate infiltration, establish a corrosion barrier for the off-road sewers, and extend sewer life for more than 50 years.

Design and Construction

“Since this was my first major sanitary trunk sewer rehabilitation, I knew that the learning curve was going to be steep,” says Dan Bennington, C.E.T. Bennington is a project manager in the Region of Peel’s CA&R Group; he was also the project manager for the Fletcher’s Creek Trunk Sewer Rehabilitation project.

“Considering this was the first large rehabilitation project for our CA&R Group, we needed to ensure that the project was designed and delivered in a way that could be used as a baseline for future projects, and incorporating all lessons learned to help us deliver future projects successfully,” he says. “This included the development of the contract documents and specifications, detailed design drawings, and overall approach to undertaking additional investigations, studies, and obtaining overall permits and approvals.”

The first phase of the project began in February 2019 and involved completing the inspection and condition assessment of identified trunk sewer sections, grading the sections or segments by overall risk based on structural defects and operational/service defects, and making recommendations for post-inspection monitoring or rehabilitation.

Upon completion of the condition assessment, the design phase included the recommendation for the identified sewer sections with structural and service deficiencies for rehabilitation with a combination of CIPP lining and mechanical seals. Recommendations for maintenance holes included the elimination of infiltration by chemical grouting and the replacement of ladders and platforms to comply with Region of Peel standards.

“A significant challenge on this project was the depth of the existing sewer and the amount of infiltration that we anticipated and experienced during construction,” says Bennington. Four sewer sections were previously attempted to be CIPP lined in 2006 but partially failed during construction due to the inability to prevent heavy groundwater infiltration by grout sealing.

Robinson Consultants investigated the implications of groundwater on CIPP, including design thickness and curing methods along with limitations. The investigations concluded that this rehabilitation would require hot water cure and that flood conditions would require the design to consider the water table depth to be 1 m above ground to match regional flood elevations within the valley. The infiltration gushers were also specified to be sealed by mechanical joint sealing prior to lining and utilization of dual continuous temperature monitoring along the invert in addition to the requirement of thermocouple temperature monitoring. This provided increased confidence that the installed liners had adequately cured to produce the required load resistance through sound infiltration elimination, temperature monitoring, and recorded evidence.

“This project has really highlighted the importance of undertaking full geotechnical investigations to quantify the potential groundwater impacts that could affect the overall success of the project,” Bennington says.

Environmental Concerns

CIPP technology provides significant environmental and socioeconomic benefits due to its ability to install a new pipe inside of the existing pipe, thereby eliminating the need to excavate trenches to replace sewers. The largest equipment required for this process includes a transport truck to carry liners to be inverted through existing maintenance holes. The other smaller equipment includes a boiler/steam truck for curing, a CCTV truck for video inspection, and flusher truck for cleaning activities. In areas with limited access or requiring minimal disturbance, such as Fletcher’s Creek, lining can also be carried out in longer shots (i.e., single installations through multiple maintenance holes), eliminating the need for accessing every maintenance hole.

The equipment required for CIPP is not needed all at once, so it can be mobilized in stages, thereby requiring a smaller footprint for operations. Although the footprint is small, there are still minimum space and capacity requirements.

“I think one of the biggest challenges we encountered was ensuring that the site had no constraints to accommodate the overall equipment to undertake the work,” says Bennington. “This includes the detailed review of access restrictions, traffic impacts including lanes closures, proximity to environmental features and the required mitigation, and having a detailed understanding of the overall bypass requirements including phasing to minimize impacts.”

Most of the sewers within the project area are located within the floodplains with maintenance holes located near the creek, which is home to Redside Dace, an endangered species with its habitat protected under the Endangered Species Act.

“The existing pathways in the project area were insufficiently wide and unable to carry the loads of the required transport trucks without considerable excavation. We knew we needed an alternative solution to minimize impacts on the natural environment,” says Muhit Tanveer, P.Eng., Robinson Consultants’ project engineer and contract administrator for Fletcher’s Creek.

To minimize disturbance to the habitat, Robinson Consultants investigated and identified the ability to utilize temporary wood matting over existing trails and grassed areas. This approach was reviewed by environmental agencies and eliminated the need for additional permitting, which maintained schedule for this critical phase of the project and resulted in minimal disturbance to the surrounding environment. To ensure these actions were taken, the use of wood matting was specified as part of the RFP requirements. Installation and restoration of these access mats were faster than other protection options presented, and as a result, the surrounding residents and stakeholders were pleased with the minimal disturbance and inconveniences experienced.

“One of the key considerations I believe minimized the overall impacts to the environment and project schedule was the requirement for wood matting to avoid constructing a temporary roadway that could withstand the equipment loading requirements,” says Bennington. “In doing so, we eliminated the need to obtain overall conservation authority permits and greatly minimized the amount of restoration requirements and associated costs.”

Moving Forward

The completion of the Fletcher’s Creek Trunk Sewer Rehabilitation project is a mark of significant progress for the Region of Peel and the CA&R Group, which was expanded significantly in the spring of 2021 to include large diameter water transmission assets. Previously, the group was wastewater-based; however, through an ongoing divisional reorganization, it made the most sense to group large diameter pipelines together.

In addition to their condition assessment and rehabilitation program development, the CA&R Group is currently undertaking a system-wide study to determine where and how real time controls (RTC) can be implemented to minimize system surcharge and overflows.

“The RTC study is looking at the overall hydraulics of the Region’s wastewater system in conjunction with future growth projections to identify opportunities to divert and store sanitary flows during wet weather events. This ‘smart’ system will ultimately leverage weather radar and forecasts to strategically open and close gates in the wastewater collection system to store flows to reduce downstream impacts on the wastewater treatment plants,” Gan says.

“As we move ahead with our program, we look forward to undertaking more capital rehabilitation projects like Fletcher’s Creek to ensure continued service to residents and businesses in the Region.”

Gan adds, “The CA&R Group, alongside our consultant partner Robinson Consultants and contractors LiquiForce, Insituform and Empipe, was able to complete this complicated trunk sewer rehabilitation project on time and on budget and bring the Fletcher’s Creek trunk sewer’s condition back within acceptable levels of service by industry standards. The availability of trenchless lining and bypass technology allowed this large diameter sewer to have several sections completely relined with minimal disruption to the surrounding community.”

With an already considerable collection system and a growing customer base, the preventative and planned maintenance undertaken by the CA&R Group will be crucial for the Region in its ability to respond to the present and future needs of its population.

“With the experience and knowledge, we gained on this project I have no doubt that future rehabilitation design and construction projects will be just as successful within the Region of Peel,” Bennington says.

Alex Zavarise is a communications specialist with Robinson Consultants Inc.