PRO Tips & PROducts Showcase – Drain Cleaning Machines

Cameras and drain cleaning machines are probably the two most important pieces of equipment in any pipe cleaning pro’s arsenal. We touched on the drainline inspection cameras in our March/April issue — check it out at pipecleaningpro.com/drainline-tv-inspection-equipment-products-showcase — in this issue we look at the cleaning machines.

These machines come in a variety of sizes and what you need will vary on the size of the project or where the clog is located. We reached out to the manufacturers to submit their latest and greatest drain cleaning machine as well as a PRO Tip.

The PRO Tips vary from buying tips to maintenance and usage suggestions. As always, for more information, and to view a manufacturer’s complete drain cleaning machine lineup, visit the website, which accompanies each product description.

Electric Eel Mfg. The Electric Eel Model C

The Electric Eel Model C is the original dual cable sectional drain and sewer cleaning machine. The Model C cleans 3- to 10-in. diameter lines with up to 200 ft of 1 ¼-in. self-feeding dual cable in 8- or 10-ft sections (that require no handling when rotating). This time-tested machine spins cable at twice the rpm of a continuous cable machine for maximum cleaning power. The unit weighs only 72 lbs., so along with the folding handle, loading and transportation is easy.

The Model C is the best unit available for tougher blockages such as tree roots and for longer runs in main sewer lines. Electric Eel Mfg., based in Springfield, Ohio since 1939, produces a full line of drain and sewer cleaning machines including sectional units, drum machines, and a full line of pipeline inspection systems.

PRO Tip

The Electric Eel Model C sectional cable machine offers added benefits in comparison to a drum-style drain cleaner. First, the sectional machine allows for 500 rpm cable rotation, twice that of most drum machines. Higher RPM offers better cleaning power. A second important advantage the sectional has involves the cable usage. Sectional cables, typically sold in 8 ft. increments, are more economical in that one section of cable can be replaced at a time. A damaged or worn section can simply be removed and replaced at a job site and can continue. A damaged continuous cable used in a drum machine will often interrupt the completion of a job until the entire cable can be replaced. A third benefit of the sectional cable drain cleaners comes from a completely adjustable clutch feature. The clutch protects the cable from overload when a tough stoppage is encountered. A fourth, is that a drum-type machine has a fixed capacity of cable length typically 100 ft or less. The sectional machine can clean to distances more than 200 ft.

For more information, visit electriceel.com.

General Pipe Cleaners Sewerooter T-4

General Pipe Cleaners’ new Sewerooter T-4 mid-size drain cleaner packs the punch and portability to unclog 3- to 6-in. lines up to 100 ft long. The Sewerooter T-4 carries 100 ft of 9/16-in. Flexicore cable to clear stubborn stoppages in 3- to 4-in. inside lines. Heavy duty 9/16-in. cable provides more torque than traditional 1/2 -in. cables offer yet can clean the same size drain lines. Need to clear tree roots and other tough clogs from 3- to 6-in. lines? Simply switch drums to 75 ft of 5/8-in. Flexicore cable. Sewerooter T-4 features a variable speed Power Cable Feed, fold-down handle, stair climbers, and truck loading wheel. Its robust, reinforced frame rides smoothly on big 10-in. wheels. Flexicore cable offers superior kinking resistance and unequalled strength with the right amount of flexibility. It’s so tough that it carries the best warranty in the business.

PRO Tip

Extending the life of your drain cleaning cables is as easy as 1, 2, 3. First, let the rotation of the cutter do the work. When clearing a clog with your machine, don’t force the cable down the drain. Think of it as a drill, not a battering ram. Second, drain excess water from the drum. After the job is done, rotate the drum so the drain hole on the back is in the six o’clock position and lay the machine on its back to allow water to drain out of the drum. And third, use Snake-Oil to preserve and protect your cables. Spray or pour Snake-Oil, or some other lubricant, into the drum and rotate it for thirty seconds to cover the steel cable and metal drum with as much oil as possible. Effective lubrication is essential for cable longevity.

For more information, visit drainbrain.com.

RELATED: Welcome to Pipe Cleaning PRO

Milwaukee Tool

The M18 FUEL Sewer Sectional Machine with CABLE-DRIVE is the first cordless sewer sectional solution. This machine allows users to clear the toughest blockages in 2-in. up to 8-in. sewer lateral lines. It also delivers the power to clear roots up to 200 ft out, providing full power at the maximum capacity of the machine. In addition, it features a CABLE-DRIVE Automatic Feed and Retract which reduces user fatigue by eliminating the need to manually pull back the heavy cable from pipes. The CABLE-DRIVE System reduces user fatigue by eliminating the need to manually pull back the heavy cable from pipes. An enclosed cable carrier ensures the best protection and containment of the mess during transportation of the cables. Each of these cable carriers can also be stacked for easier storage.

For more information, visit milwaukeetool.com.

MyTana M745 Workhorse

MyTana’s M745 Workhorse lets drain-cleaning professionals adjust cable speed on-the-fly for maximum performance and choose from two torque settings for safety. The M745 incorporates MyTana’s proprietary new SmartDrive technology. With SmartDrive, cable speed can be throttled (up to 300 rpm) to negotiate turns, strengthen cleaning force, and expedite feeds and retrievals — or reduced (as low as 100 rpm) for tackling obstructions and debris. SmartDrive also includes calibrated torque protection to safeguard the operator and extend cable life. The M745 comes equipped to work in 3- to 4-in. lines with 100 ft of cable, slip-joint fittings, autofeed, blades and accessories. A sinkline kit is available to address 1 1⁄2- to 2-in. lines, and reels can be swapped without tools with the quick-release design of the drive system. The M745 is compact to fit in tight spaces, has non-skid feet and balanced weight for stabilization during operation and transport, offers a telescoping adjustable handle that retracts easily for storage, and has built-in stair-rollers.

PRO Tip

Cable machines do punishing work. You want one that will last for years, so investing in quality is a no-brainer. If you are considering a larger machine, here are some things to consider: Upright models are generally more compact and can maneuver on stairs or into tight spaces. Sled-style machines offer a low profile, but you may want to separate the reel from the frame when transporting. Cable reels that are easily removed save time by simplifying transport and facilitating quick reel swaps for longer lines. If you’re relying on an electric machine with long cords, consider gas-powered options. An automatic feed/retriever makes it easier to perform tough tasks like pulling out roots wrapped around cable. Buy from a brand with a reputation for reliability. Choose a manufacturer that provides parts inventory, support and quick turnaround should repair work be necessary.

For more information, visit mytana.com.

Picote Mini Cleaner

The Picote Mini Cleaner is a gamechanger for high-speed cleaning in 1¼- to 3-in. pipes with the ability to navigate multiple 90-degree bends, or even reinstate through tricky 2-in. P-traps. Picote your own way; the Mini Cleaner comes with a cleaning or a cutting package and is also available with an integrated camera system. Choose from an impressive range of additional tools for cleaning, cutting, reinstatements, removing blockages and restoring flow. High-performing, powerful and safe – the Mini Cleaner features a customized safety clutch and 50 ft of rotating shaft housed inside specialized, flexible outer casing making it safe for the operator to hold. Simply add a Mini Coating Pump to your Mini Cleaner to add Picote Brush Coating to your business offerings, a great upsell that gives peace of mind to customers. Picote offers an entire range of multi-use Millers to choose from for cleaning and rehabilitating up to 12-in. pipes.

PRO Tip

Always make sure that the pipe has been opened and ventilated to prevent any gases accumulating. Select the correct size tool for the job; use the largest size that will fit inside the pipe and go around any bends. Place the machine as close as possible to the pipe opening. The optimal rotation speed of the Mini Cleaner is between 900 and 2,100 rpm (speed settings 2 to 4). Rotation speed is best kept to 900 rpm when moving the tool around 90-degree bends and 2-in. P-traps, however, if it won’t go around then reduce the rotation speed down to speed setting 1. Do not force the tooling through the pipe – let the tool do the work! When using the Mini Cleaner keep moving the tool backwards and forwards to prevent the outer casing from overheating. Use either flowing water or vacuum extraction (dry cleaning) to remove the debris.

For more information, visit picotesolutions.com.

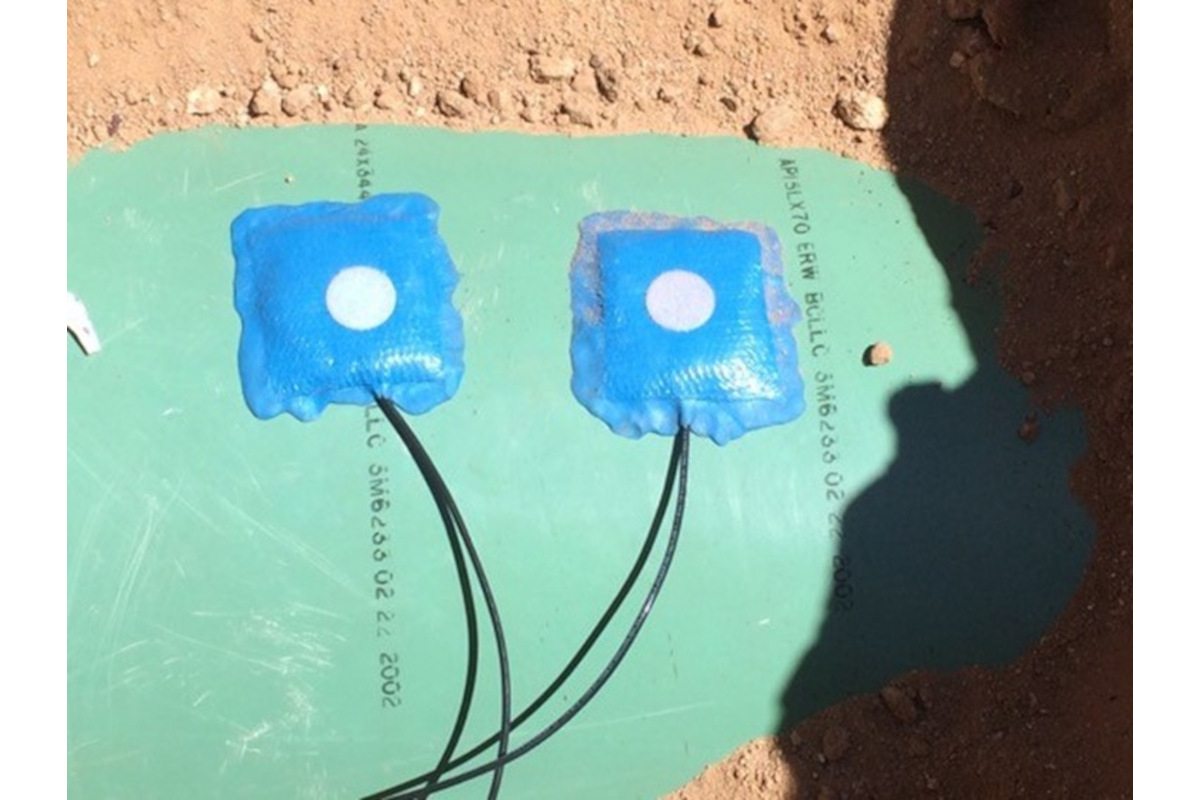

Ridgid FlexShaft K9-102 and K9-204

The RIDGID FlexShaft K9-102 and K9-204 Drain Cleaning Machines quickly and efficiently deliver wall-to-wall clean. The K9-102 cleans 1 ¼- to 2-in. residential and commercial pipes up to 50 ft and the K9-204 cleans 2- to 4-in. pipes up to 70 ft. Lightweight and fully contained machines, they are used in conjunction with a full suite of specialized accessories designed for clearing grease, sludge, small tree roots and soft blockages with less mess and enhanced speed. They utilize powerhouse chain knockers that expand to the size of the pipe to quickly clear the entire circumference. The chain knockers are connected to a flexible, nylon-sheathed cable that is housed in a fully enclosed drum and powered by a cordless drill attached to the driveshaft. Designed with efficiency and cleanliness in mind, FlexShaft machines allow for inspection cameras to remain in-pipe throughout the entire drain cleaning process for maximum efficiency.

PRO Tip

There is a learning curve when switching from traditional drain cleaning cable to high-speed cable. Understanding speed and finesse is key to having the machine last and to optimizing your return. Keeping water running and cleaning from downstream are also important to note as this keeps the end of the cable spinning as freely as possible. Also be sure to follow the recommended settings in the manual so the drill and high-speed cable work most safely and effectively.

For more information, visit ridgid.com.

RELATED: Surgical Precision – Top of the Line Equipment Helps Rhode Island Contractor Succeed

Spartan Tool Revolution M1

The Revolution M1, powered by Picote is designed to navigate P-traps, U-bends and pipes with multiple 90-degree bends. It is made with a specially produced, highly flexible outer-casing, which is durable, flame, abrasion- and chemical-resistant. The 1/3-in. cable with flex casing comes with 50 ft of cable for use in 1¼- to 3-in. lines. For safety, electrical components are GFI protected and it’s equipped with an industry-leading clutch system. The reel is designed to allow the cable to feed from the front or rear of the machine so the unit can be operated while standing or kneeling beside it, or while comfortably sitting on top of the unit. Users will find the most difficult part of operation is deciding which tooling to use. There are more than 40 different chain, cutter and cleaning attachments available for the M1 and over twice that amount for its big brother the M2.

PRO Tip

The new Revolution lineup from Spartan is a business owners dream. The M1 is capable of completely cleaning lines from 1 ¼ to 3 in. with minimal effort. Typically drain cleaners are forced to carry two and in some cases four different pieces of equipment to accomplish the same results within such a broad range of pipe sizes. The M1 outperforms jetters and mechanical equipment within its range. The Revolution line is known for its ease of use and durability, but often maintenance is overlooked. The M1 is designed to facilitate cleaner operation. Since the cable is inside a casing the equipment, operator and workspace require little to no cleanup when completed. There are no grease points. The only required maintenance is the occasional cleaning and oiling of the cable with paraffin oil, which takes about 15 minutes and should be monthly or quarterly depending on usage.

For more information, visit spartantool.com.