NASSCO Report – Utilizing Trenchless Rehabilitation to Save a Pool

Trenchless rehabilitation methods can be applied in some, less than traditional situations. This is detailed in the case of “The Summer that almost got away.”

Roto-Rooter was contacted by an apartment community to diagnose an issue with a pool that was continually losing water. As a result, the pool had to remain closed during the late spring and early summer months. This left residents frustrated during an exceptionally hot season.

Approximately 250 ft of 2-in. and 3-in. PVC lines were suspected of having multiple leaks. These lines ran out from the pool house all the way around the pool. They were situated below the pool deck and encased in concrete. The customer’s priority was to restore the pool quickly with minimal disturbance to the property.

The Solution

The ever-evolving trenchless industry is becoming increasingly prevalent when creating solutions for customers in the field. There are numerous methods being utilized. These methods have proven to be efficient and effective when rehabilitating both sewer and water pipes. They are designed for minimal disruption to not only the facilities but also to the people residing and working at these locations.

After a thorough inspection of the piping and with the help of Picote Solutions, we determined that a brush coating product was a perfect fit for this application. By applying two coats of the 100 percent solids epoxy resin, all the pipe joints would be sealed. This addressed any hairline cracks and created a durable coating inside the entire pipe system.

Only one access point was excavated between the pool house and pool, allowing the team to bypass a challenging 2-in. schedule 40 “tee” that was simply too tight to navigate. All other work was performed through the existing drains and jet openings.

The Process

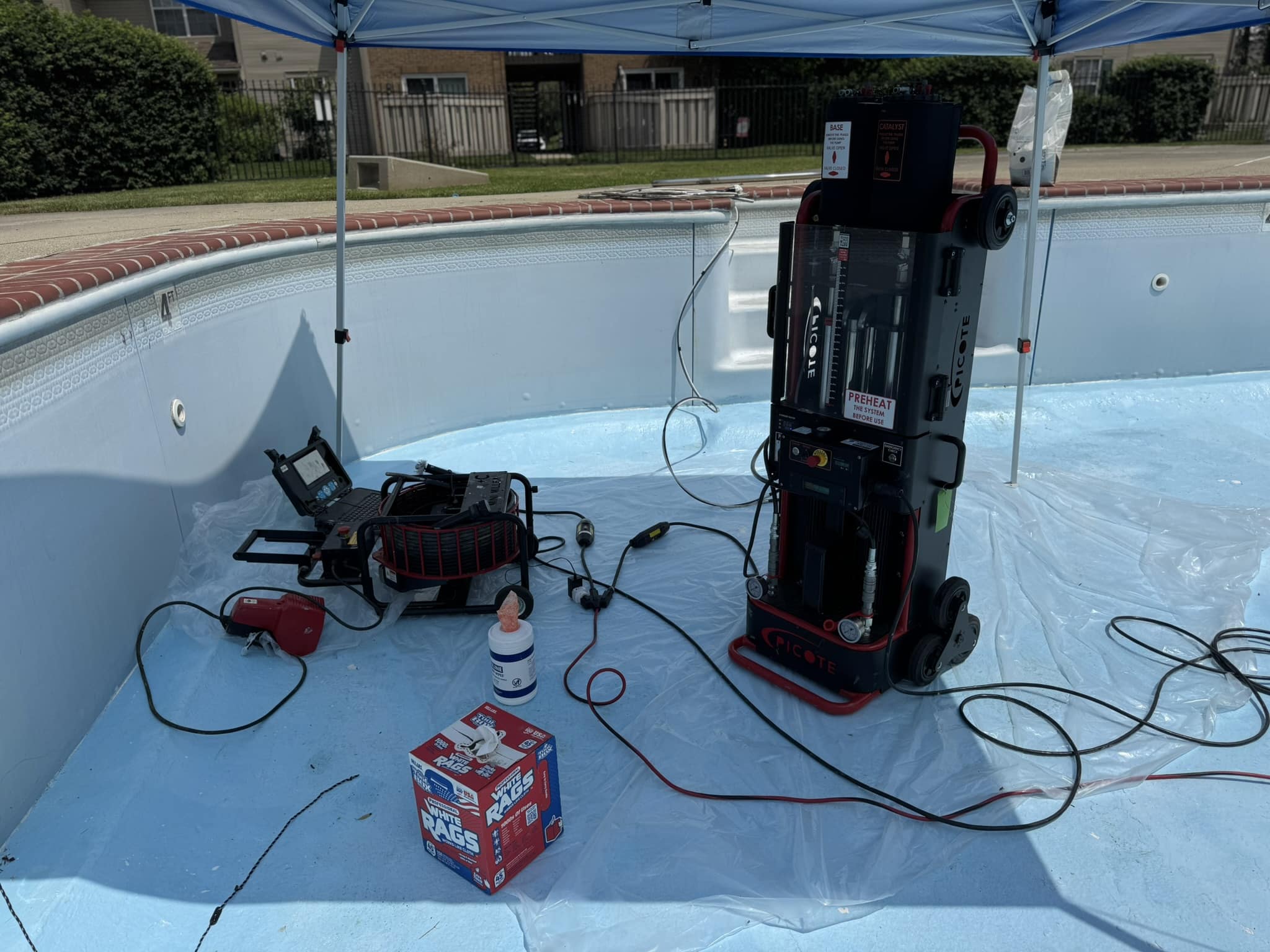

Before applying the epoxy coating, the pipes required thorough cleaning and descaling. Using a battery-powered cutter, the team removed debris and scuffed the pipe walls to ensure strong epoxy adhesion. The lines were then flushed, the pool drained, and the piping dried with a Picote heater.

With the system prepped, two coats of epoxy were applied through all existing and prepared access points. This was accomplished by running a milling machine fitted with specialized brushes down each line, ensuring even coverage. An inspection camera was used throughout the process to provide continuous visibility and quality control.

The Results & Impact

When compared to a traditional dig-and-replace method, the advantages of trenchless rehabilitation were clear. This approach minimized or eliminated costs tied to permits, disposal, and reconstructing the pool deck. It also avoided the time-intensive process of excavating, replacing, and backfilling the entire pipe.

The project was completed with exceptional efficiency. It took two days for cleaning and coating, one day to backfill and close the single excavation point, and one day to refill the pool. In total, the project was completed in just four days. By contrast, traditional excavation could have taken several days or even weeks. This includes pipe replacement and pool deck reconstruction.

Use of trenchless methods also creates a safer, less physically demanding work environment. This not only reduces the risk of onsite accidents, but also supports the long-term health and careers of our technicians. At the same time, the property remained intact with no major repairs needed after the work was finished.

In the end, we delivered a durable, long-lasting solution while minimizing downtime, cost, and disruption. This project highlights the versatility of trenchless pipe rehabilitation technology. It shows how the right assessment and application can produce outstanding results, even in complex environments.

Best of all, by choosing this minimally invasive method, residents and guests were able to get back to enjoying their pool and the rest of their summer in the sun.

Ben Irvin is with Roto-Rooter Corp. and a member of the NASSCO Lateral and Building Pipe Committee.

- Azuria Water Solutions Adds Waterline Renewal Technologies to its Roster

- Puris, Per Aarsleff Partner to Strengthen Lateral Rehab in Canada

- Vortex Companies Rebrands Grout Line to Maverick Grouts

- Vermeer Unveils VXT400, VXT500 Vacuum Excavators

- How to Reestablish Service Connections After In-Building CIPP Rehab

Next Up

2026 CUIIC Academy Spring Summit | March 3-5, 2026 | Mississauga, Ontario | Learn more