NASSCO Report – NASSCO’s PACP Quality Control Guidelines Used in Canada

NASSCO’s PACP has largely been adopted as a North American standard for the internal condition assessment of sewer pipes. PACP data, for many years, has been used to define the serviceability of a pipe and to prioritize and recommend appropriate maintenance and rehabilitation interventions. System owners, managers, finance departments and engineers rely on the quality and consistency of PACP data to facilitate repeatable and auditable decision making and system support to manage assets.

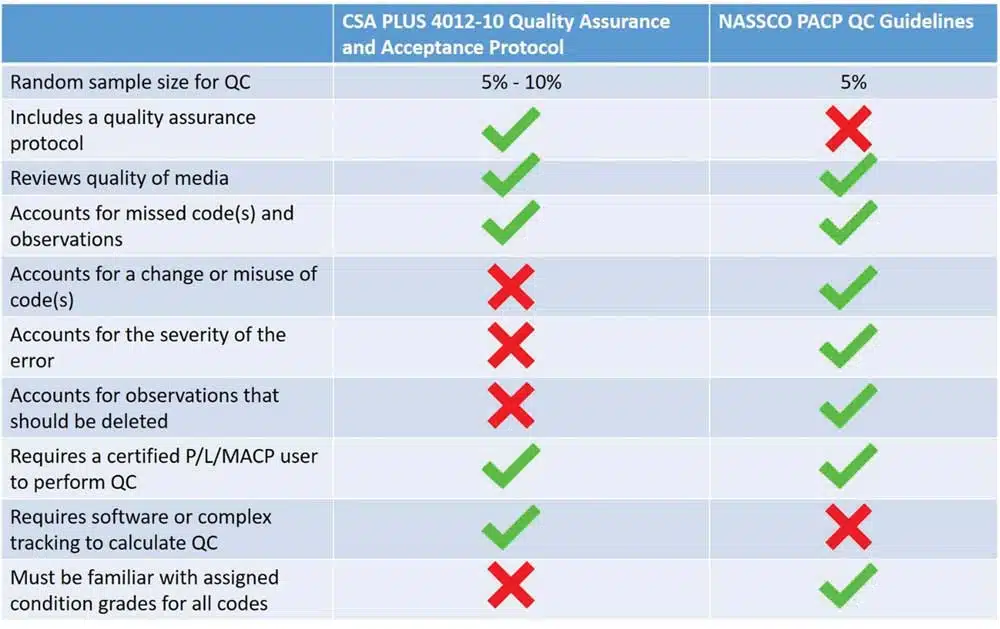

For more than a decade, Canadians have referenced CSA’s Technical Guide Visual Inspection of Sewer Pipe PLUS 4012-10 (2010) Section 7 Quality Assurance and Acceptance Protocol for QA/QC procedures. This document identifies stakeholder roles and responsibilities, outlines a quality assurance program from project commencement to conducting peer reviews throughout the data collection process, as well as control procedures to examine the quality of the inspection medium and measure the accuracy of the coding.

NASSCO has recently published PACP Quality Control (QC) Guidelines and many municipalities in Canada are already implementing these QC procedures to ensure the quality of their PACP data at either the individual operator or project submission. NASSCO’s PACP QC Guidelines may be considered unique as they assess all aspects of a sewer inspection deliverable including:

- The survey deliverables standards and formats for the video, photos, database and report

- The quality of the inspection camera operation including set-up, cable calibration, appropriate crawler speed and stopping to view defects and features

- The quality of video and images including removing obstructions, clean camera lens, sufficient lighting and minimal fogging

- The quality of PACP recording in both the Header and Details tables.

Canadian municipalities and consultants have been thrilled with this quick, simple, and user-friendly QC process to ensure the quality of their sewer inspection data. The QC Guidelines help to confirm that a PACP-Certified professional in good standing is responsible for producing the inspection survey and that the data is collected within the PACP standard and delivered to the client in a certified NASSCO PACP Interchange Database. There are essentially four steps within the PACP inspection deliverables that undergo evaluation for pass or fail:

- Submission of files and formats

- Quality of video and inspection visibility

- Accuracy of information within the Header table

- Accuracy of information within the Details table

Positive aspects of the PACP QC Guidelines are the suggested sample size for QC, the flexible Pass/Fail threshold, who is eligible to perform the QC and the deduct scores for the Details table. CSA’s PLUS 4012-10 document suggests the following formula:

Number of entries that should have been made – Error count)

Accuracy level = X 100%Number of entries that should have been made

The above calculation suggests that the reviewer code a survey in its entirety to determine the number of entries that should have been made. An error count does not take into consideration the severity of the error.

For example, if 10 percent deposits settled fine (DSF) is the correct observation, one operator calls out 10 percent deposits settled gravel (DSGV) while the other operator calls out 20 percent DSF. In both cases, only one error was made however, calling 20 percent blockage versus an actual 10 percent blockage may result in a different urgency or criticality assigned to the pipe for maintenance. One error is more severe as it has more consequence than the other error. In addition, perhaps an operator missed a Tap code within a pipe section that only had two taps, this would suggest a failing inspection as it would result in a 50 percent accuracy based on the calculation described above. On the contrary, the same error can be made; one missed tap code in a section with 10 taps observed and that would result in a 90 percent accuracy. In this example, the same error was made, however, one survey passed while the other failed.

Due to this, deduct scores are a preferred method to measure the competency of an operator to record observations and defect codes. Although this method for the Details table suggests a very qualified PACP Professional performs QC (not a terrible notion) as they must be very familiar with the condition grades associated with each code, this method is a simple check of a small, medium, or large error. The PACP QC Guideline has rules that define a small (deduct one point), medium (deduct 3 points) or large (deduct 5 points) error from a possible 100 points. It is up to the owner to define within their contract their preferred pass/fail threshold although NASSCO suggests a minimum passing threshold of 90 points that would allow for two large errors.

The table above compares the two methods.

The PACP QC guideline for reviewing and assessing collected PACP data may result in more consistent information. In return, this information will allow for a more actionable interpretation of defect data and pipe condition and thus help to ensure a more resilient underground network.