Microtunnelling Key to WALK Bridge Replacement Project

Since its initial construction more than 125 years ago, the Norwalk River Railroad Bridge – commonly known as the WALK Bridge – in Norwalk, Connecticut, has outlasted its ideal lifespan. This has led to the potential for operational failures and increased vulnerability to weather damage. The bridge is a vital part of the Northeast Corridor (NEC), the busiest passenger rail corridor in the United States.

Michels Trenchless Inc. used a microtunnel boring machine (MTBM) to build two parallel tunnels. These tunnels were critical components of the $1 billion initiative to replace the WALK bridge. The new bridge is a modern vertical lift bridge designed to enhance reliability, safety, and capacity.

The 564-ft-long, four-track truss bridge not only supports rail traffic, but also carries critical utility infrastructure. This includes overhead catenary systems installed in 1907 and subsequently installed electrical and communication lines.

Since the 1990s, the bridge has undergone several repairs. However, recurrent failures prompted the Connecticut Department of Transportation (CTDOT) to enact an Emergency Declaration to replace the bridge in 2014.

A Trenchless Solution

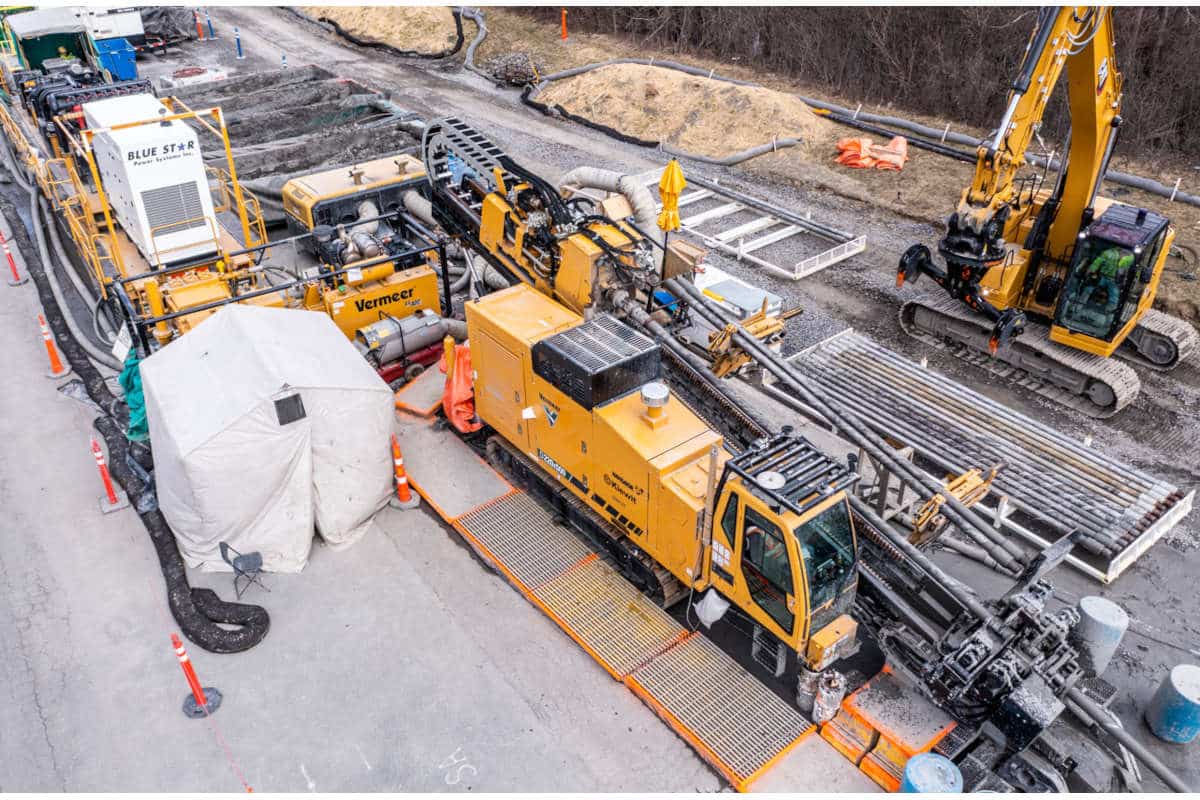

Michels Trenchless began work in August 2024. Their goal was to ensure that essential utility services, including overhead electrical and communication lines, were safely and permanently transitioned underground without disrupting NEC rail operations above ground. To achieve that goal, Michels constructed two 450-ft tunnels (900 linear feet total) beneath the Norwalk River in Norwalk, using conventional microtunneling methods. Each tunnel consists of a 63-in. outside diameter fiberglass reinforced polymer mortar (FRPM) casing. Upon tunnel completion, Michels installed conduit bundles within the casings to accommodate the relocated power and communication lines. The work was completed in April 2025.

Choosing Microtunneling

Relocating the utilities from overhead to underground was a prerequisite to facilitate this transformation, prompting crews to utilize microtunneling techniques. Microtunneling is used for the construction of smaller diameter tunnels. Due to their size, operators cannot drive the tunneling machine. Instead, remotely operated MTBMs and jacking methods are combined.

The area beneath the Norwalk River posed challenging ground conditions due to high groundwater levels and soft, unconsolidated soils. This made pressurized face tunneling necessary to maintain stability and avoid settlement or blowouts.

Crews also faced tight working constraints. The site was heavily congested with simultaneous construction activities, limiting available space for staging. However, microtunneling allows for a smaller footprint while providing the necessary precision and control.

Subsurface Challenges

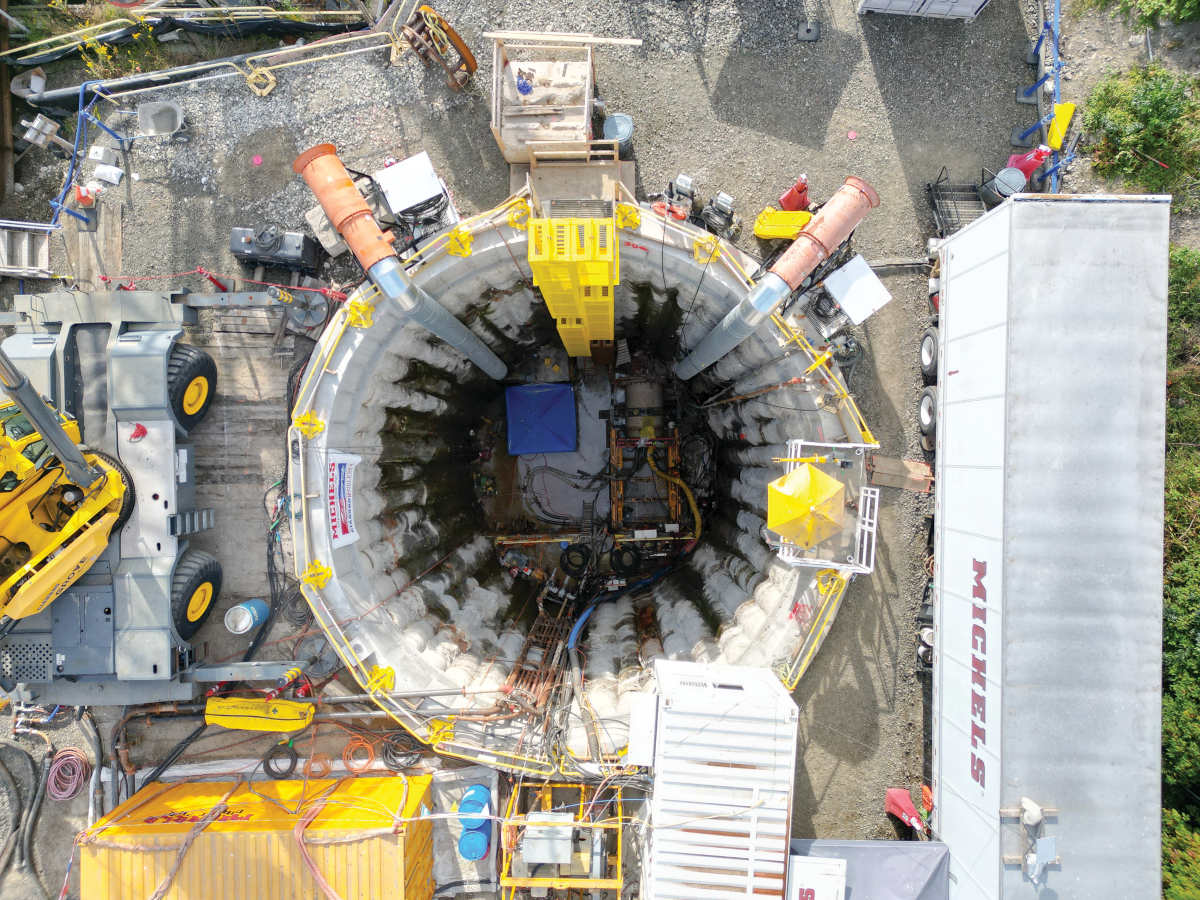

Despite thorough planning, the project encountered significant subsurface challenges. Approximately 20 ft from the reception shaft on the first tunnel drive (North Tunnel), the MTBM struck an unexpected obstruction. This severely damaged the cutterhead. Michels engaged its commercial dive team to assist in the execution of an emergency recovery plan involving two rescue shafts.

A vertical rescue casing was installed, allowing divers to access and free the MTBM from the obstruction. The machine was immobilized again after traveling a short distance due to unforeseen subsurface conditions.

Crews installed a second steel casing that was jacked and hand-mined horizontally around the MTBM. Divers assisted with precision excavation.

Once fully encapsulated within the telescoping steel casing, the MTBM was safely extracted and transported for repairs. During both recovery efforts, the support of excavation (SOE) systems was temporarily flooded to stabilize the soil and manage groundwater pressures.

Following repairs, the MTBM was redeployed and completed the second tunnel drive with no further complications.

Successful Completion

The microtunneling work performed by Michels at the WALK Bridge demonstrates trenchless innovation, adaptability, and technical excellence under pressure.

From completing complex underwater crossings in a constrained urban environment to managing emergency rescue operations in real time, the team delivered a critical scope of work. This work directly enabled progress on one of the NEC’s most ambitious infrastructure upgrades.

Benoit Cousineau Cote is a senior project manager with Michels Trenchless.