Meets the Needs of Expanding Communities

January 1, 2008

Last year, Thomas Township, Mich., was faced with the task of meeting the growing water and sewer needs of a large, growing complex of two industrial facilities and a handful of surrounding homes. One of the industrial facilities, which manufactures raw materials for the computer chip and solar industry, was quadrupling its size.

Last year, Thomas Township, Mich., was faced with the task of meeting the growing water and sewer needs of a large, growing complex of two industrial facilities and a handful of surrounding homes. One of the industrial facilities, which manufactures raw materials for the computer chip and solar industry, was quadrupling its size.Though currently a rural area with more of a focus on agriculture, Thomas Township has experienced both industrial and residential growth in recent years. To serve this expansion, the township’s water and wastewater infrastructure were being upgraded to supply a greater capacity. Some homes were affected, but no new homes were added to the existing service district. The design, however, allowed for future residential capacity expected in the area, due to the jobs created by the expanding industrial facility.

One of the biggest projects of the infrastructure upgrade was a nearly 13,000-ft sanitary sewer forcemain installation. The lengthy pipeline would run alongside Gratiot Road, a heavy-trafficked, four-lane Saginaw County portion of State Highway M-46. This, and the location of some utility lines nearby, presented some challenges.

Thomas Township hired Spicer Group Inc., of Saginaw, Mich., as consulting engineers for the project. Spicer Group designed the sewer forcemain and specified horizontal directional drilling (HDD) as the method of pipe installation.

“The pipeline needed to run parallel to M-46, and we were going to have to bore under a river crossing in one portion of the project,” says John Olson, project manager for Spicer Group. “Most importantly, the right of way was a high-profile residential area path with a lot of driveways we didn’t want to disrupt. Easements were not an option. HDD would create less disturbance and less clean-up, making it an ideal choice for this type of project.”

S&S Directional Boring Ltd., of Bryan, Ohio, was awarded the general contractor bid for the job and began work last May. Spicer Group gave two pipe options in its specification — CertainTeed Certa-Lok Yelomine PVC pipe and HDPE pipe, leaving the final choice up to the contractor. S&S chose Certa-Lok Yelomine, because of its easier installation process and lack of clutter.

“I liked the Certa-Lok Yelomine pipe because it keeps you from impacting driveways,” says Tod Schlachter, partner of S&S Directional Boring. “It comes in 20-ft lengths and you put it together one piece at a time while installing it vs. having hundreds of feet of fused pipe strung out throughout the neighborhood. It only takes us 30 to 40 seconds to put a joint together with the Certa-Lok, so it’s a real breeze.”

A total of 12,700 ft of Certa-Lok Yelomine was required for the project, 9,000 of which would be installed via HDD. The remaining 3,700 ft, which would run under a bean field, would be laid using the open-cut method. Pipe was purchased from distributor Michigan Pipe & Valve’s Saginaw branch. S&S Directional Boring had two crews of four working on two drills — a Vermeer 33×44 drill with 33,000 lbs of pullback and a Vermeer 36×50 drill with 36,000 lbs of pullback. Both models have a rotary torque of 4,995 lbs.

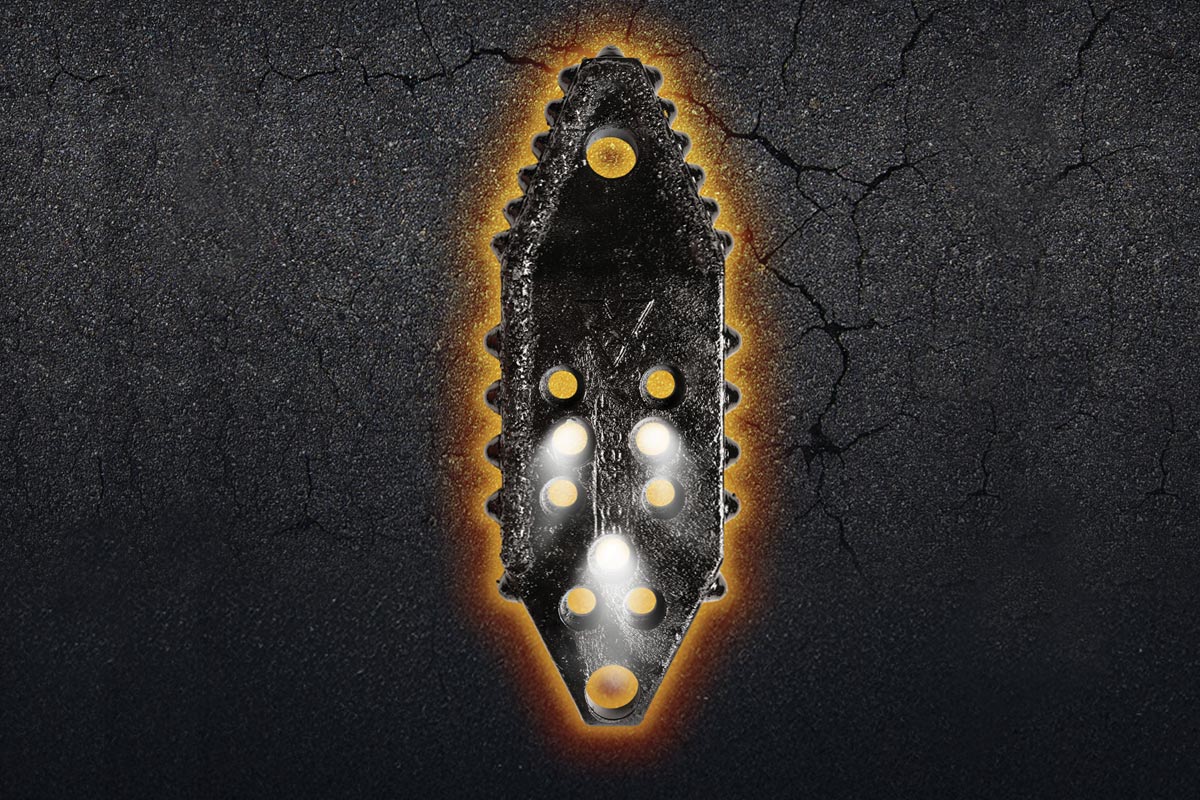

Drilling through a mix of sand, clay and glacial till, the crews made 10 bores ranging from 400 to 1,100 ft and from 6 to 12 ft in depth. To get under Swan Creek, which was actually a small river, the crews needed to make a 650-ft bore 30 ft in depth. The crews pre-reamed each bore before pipe installation with 16-in. fluted reamers. On some bores, they trailed rods through the hole and other times, they pushed the reamer back through the bore.

Drilling through a mix of sand, clay and glacial till, the crews made 10 bores ranging from 400 to 1,100 ft and from 6 to 12 ft in depth. To get under Swan Creek, which was actually a small river, the crews needed to make a 650-ft bore 30 ft in depth. The crews pre-reamed each bore before pipe installation with 16-in. fluted reamers. On some bores, they trailed rods through the hole and other times, they pushed the reamer back through the bore.After each ream, pipe was assembled piece-by-piece as the backreamer pulled it back through the bore.

The biggest challenge was drilling around utilities, Schlachter says.

“For the majority of the project, we had a major telephone duct bank lying either beside us or directly on top of us, so we didn’t enjoy that too much,” he says. “In order to drill under and along side of the phone duct bank, we located the phone bank every 100 lf for depth and running line. With the help of our DigiTrak Eclipse locators, we were able to acquire our signal for locating purposes.”

The Swan Creek crossing also created a bit of a challenge for the S&S Directional Boring crews. “Swan Creek had an existing force main and the phone duct already crossing the area,” Schlachter says. “We had to roll to the back side of these utilities and go quite a bit deeper than any pre-existing plans we could find of the area.”

After successfully completing the bore, the crews attached the 16-in. reamer and completed the pre-ream. They lost flow during this phase three to four times and pushed the reamer out in order to clean the hole. Upon the suggestion of a Baroid Drilling Fluids representative, they mixed seven bags of bore gel, two bags of No Sag per 1,000 gal of water and two bags of Quik Trol LV per 1,000 gal of water. When this drilling fluid mix was used, the crew was able to pull the pipe through without any frac outs into the river. The Swan Creek crossing was now successfully completed.

Minimizing disruption to the residential area and on the highway was the easy part, thanks to successful HDD pipe installation. “The pipe was installed just off the edge of Michigan 46,” Schlachter says. “We were able to close off the shoulder and work continuously off it. This caused so little disruption that people didn’t even realize the project was going on. Some of them asked us when were going to put the pipe in after it was already done. I think that was the biggest compliment.”

Steve B. Gross, P.E. is director of marketing for CertainTeed’s Pipe Business.