Identifying Water Service Line Pipe Materials Using Machine Intelligent Technology

One of the most far-reaching pieces of legislation – the Bipartisan Infrastructure Law – is now helping to fund drinking water projects across the United States. In addition, the U.S. Environmental Protection Agency’s (EPA) Revised Lead and Copper Rule requires water utilities to complete detailed water service inventories, mapping, and replacement of 100 percent of lead service lines that are utility-owned and private property-owned. EPA estimates there are more than 9 million lead lines connecting homes to water systems in the United States.

Water systems are facing several challenges in developing service line inventories. In addition to having poor records for utility-owned pipe installations connecting water mains to curbside meters, there is little to no information available that identifies pipe materials on private property – which was not the responsibility for public, private or municipal water companies before enactment of the law.

The most common way to determine whether water pipes are made of copper, galvanized steel, lead or plastic is to excavate to expose the pipe and test with a magnet. Few, if any, cities have successfully identified all their water services and respective pipe materials by parcel or customer address.

Not even the plight of the City of Flint, Michigan, provides a good model for other cities to follow.

Representing the most closely identified city where the adverse health effects of lead-contaminated drinking water were widely documented and aided by federal and state intervention, a recent lawsuit filed against the City of Flint stated that the city still needed to assess 26,000 homes or 82 percent of the city’s 31,578 homes.

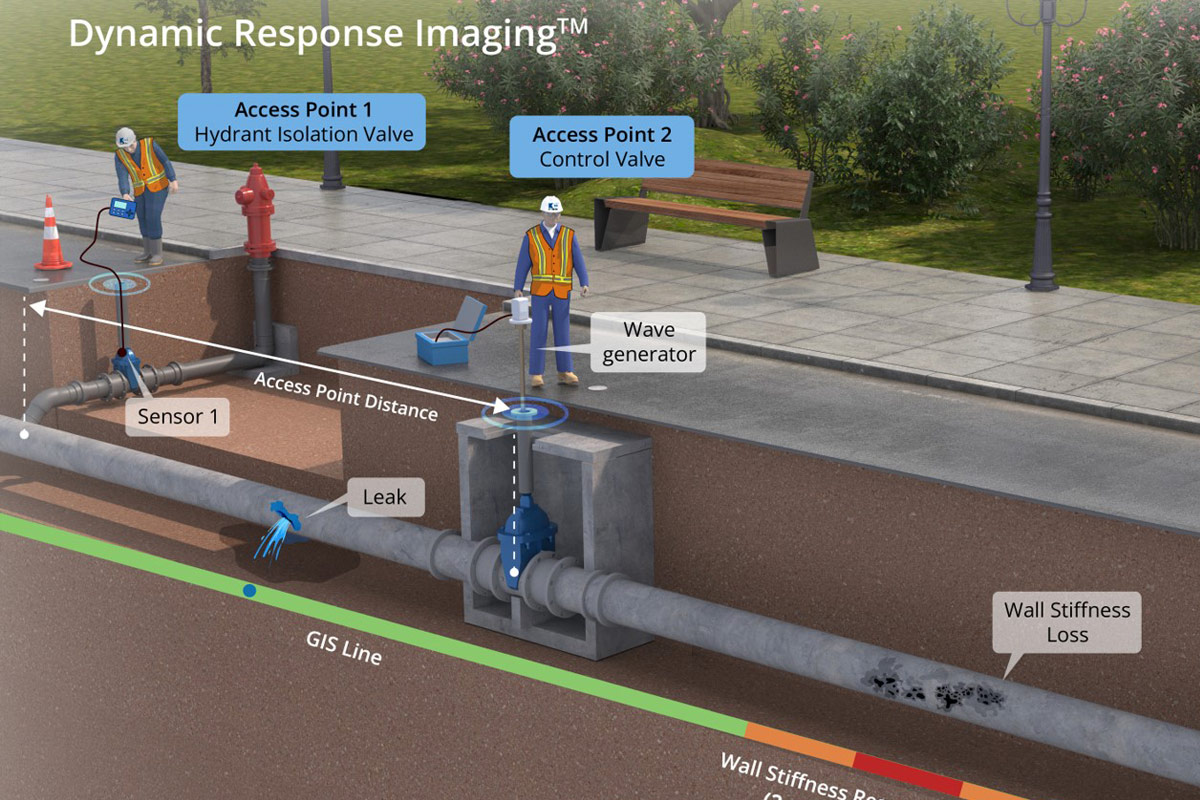

While geographic information systems (GIS) and predictive modeling applications can be used to provide probabilities for locating lead pipes, information can be inconclusive, inconsistent or incorrect. Field verification of utility-owned and private property-owned service materials is required before pipes can be scheduled for replacement.

This is not exactly what the City of Rock Hill, South Carolina, had in mind when reviewing its options to develop a comprehensive water service line inventory by the EPA deadline of Oct. 16, 2024.

Seeking an Alternative

Looking for an alternative, administrators in Rock Hill sought a trenchless product that could assess buried water service pipes and they were presented with Electro Scan’s SWORDFISH solution.

Despite being founded in 1852 as a depot and watering station on the Charlotte and South Carolina Railroad, Rock Hill’s housing data shown in Figure 1, indicates a Median Year Built of 1993 – well beyond 1986 when lead pipes and lead connectors were banned by the EPA.

“We knew that the EPA had listed electrical resistance testing as an alternative method to help inventory water service lines as part of its EPA Tools & Resources Webinar: Identifying Lead Service Lines in the Community (Oct. 26, 2022),” said Maurice Walsh, P.E., PWAM, utility engineering manager, Utilities – Water & Sewer, City of Rock Hill. “After additional research and reference checks, we confirmed Electro Scan’s ability to tell the difference between copper and lead pipe materials, using its new SWORDFISH product.”

Not wanting to unnecessarily dig up customer yards, sidewalks and streets, the City invited Electro Scan Inc. to demonstrate how it would work.

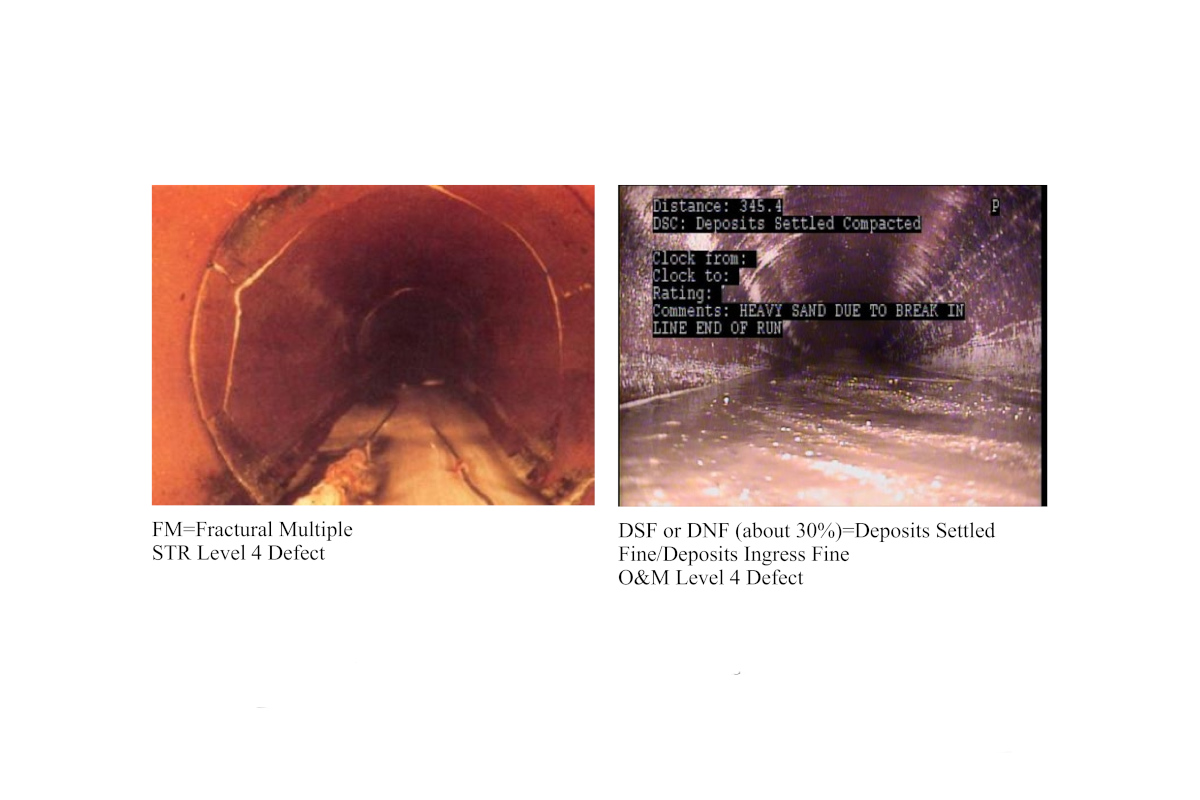

Founded in 2011, Electro Scan’s patented low-voltage technology was already proven to correctly assess leaking sewer joints typically missed by closed-circuit television (CCTV) cameras and defects in cured-in-place pipe (CIPP) liners not properly watertight.

After confirming lead joints in asbestos cement pipe in a 2015 pressurized water main investigation, Electro Scan reengineered its solution to enter smaller diameter service lines ranging from ½ to 3 in. diameter.

Measuring the change in electrical resistance as its probe moves through a pipe allows SWORDFISH to automatically identify copper, galvanized, lead and plastic pipe materials, including multiple pipe materials in the same pipe – all without operator intervention or data interpretation.

Machine-intelligent automated readings are then transferred to a Microsoft Surface tablet computer via Bluetooth in real-time during each survey, where additional photos and data entry can be added before uploaded to the Electro Scan’s Critical Water cloud application.

Based on field trials that confirmed buried pipe identification, the City of Rock Hill purchased two SWORDFISH units, including pressurized insertion tube, Microsoft Surface tablet computer, licensing to access the Electro Scan Critical H2O cloud application, spare probes, and integration to the city’s GIS.

As a result, field verifications will be focused on homes built before 1989, representing approximately 14,000 or 44 percent of the homes in the city.

The City of Rock Hill has been satisfied with its decision to adopt SWORDFISH and has even received calls from the EPA confirming its results.

The Lead & Copper Rule

Recently, the EPA published its proposed changes to the Lead and Copper Rule Revision, called the Lead and Copper Rule Improvements (LCRI).

Representing an accelerated and expanded set of proposed modifications, the EPA’s LCRI would introduce significant enhancements, including a mandatory 10-year replacement requirement for lead and galvanized requiring replacement (GRR) service lines, continuous verification of unknown service lines, and a reduced action level of exceedance from 15 parts per billion (ppb) to 10 ppb.

Key LCRI Recommendations:

- Require water systems to include connector materials in the service line inventory.

- Prohibit water systems from partially replacing lead or GRR services, unless part of an emergency repair.

- Require a street address of each service line and be made publicly accessible.

- Not limit inventory methods so water systems could take advantage of new ways to identify pipe materials.

- Create a market for service line material identification technologies.

- Establish a deadline to specifically identify UNKNOWN pipe materials for all service lines.

- Require water systems to re-inspect a service if the Customer thinks assigned material is incorrect.

- Require Customer Notice if pipe disturbances occur due to potholing or other inventorying efforts.

It is crucial to note that the LCRI has yet to undergo the legislative process before becoming law, and specific steps will be followed, with the anticipated effective date after baseline water service inventories are due Oct. 16, 2024.

Chuck Hansen is the chairman and CEO at Electro Scan Inc. and Hansen Analytics LLC.