How to Select the Right Sliplining Pipe

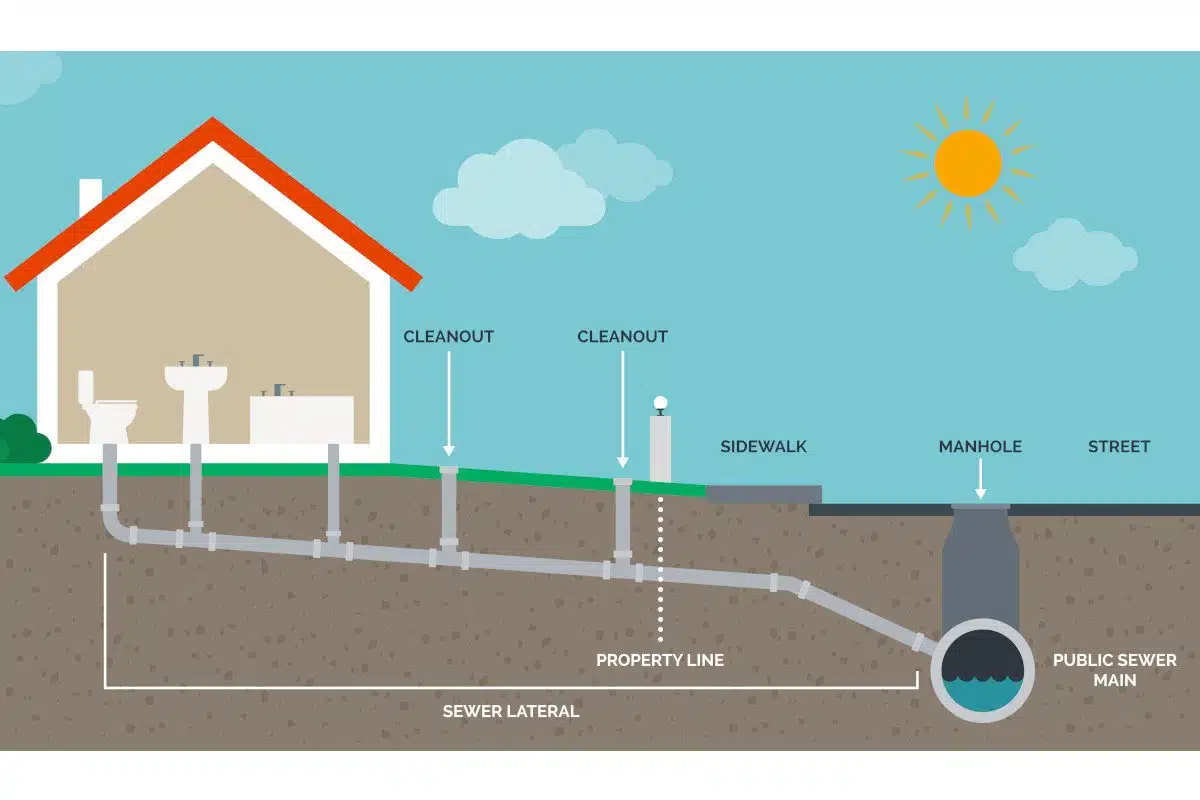

Owners and designers today are faced with the challenge of rehabilitating extensive infrastructure systems around the world. One widely used method for rehabilitating existing culverts and sewers is sliplining.

While effective, sliplining comes with various challenges and critical considerations, including but not limited to:

1. Inspection Requirements

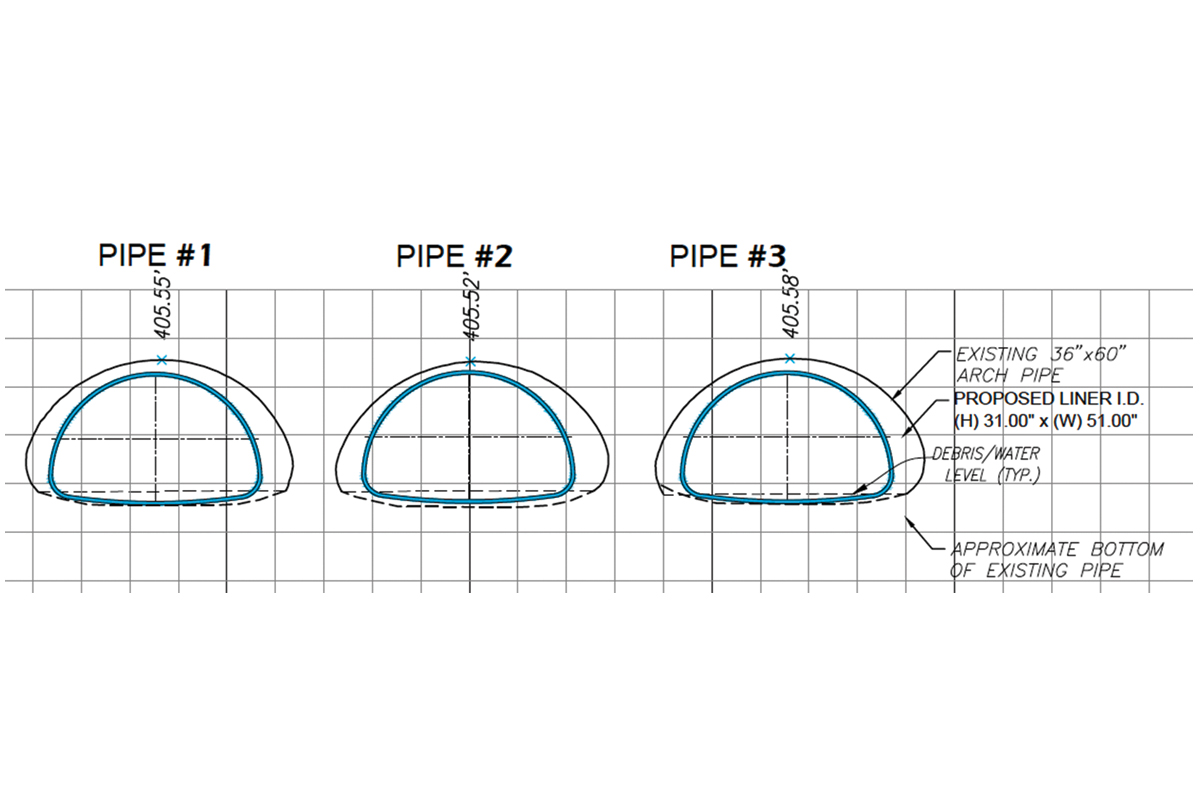

What level of inspection is necessary for the host pipe? Is a basic visual inspection with a tape measure sufficient, or should more advanced techniques such as LiDAR scanning and point cloud data collection be employed to accurately assess changes in geometry, directional changes, and other critical features? Prior to ordering any bespoke or custom liners – it is always good practice to run an inexpensive mandrel or template through the host pipe.

For example, a wooden template with an x, y, and z dimension representing a piece of the soon-to-be-ordered liner pipe is an inexpensive way to ensure that a liner will fit inside the host pipe.

Another example, in New York, visual inspection was followed by LiDAR inspection on a triple barrel pipe arch. It had noticeable deformation in the invert and stagnant bed load consisting of small rock and silts. The owner and engineer were able to employ the use of GRP by Channeline International to provide the proper geometry along with an estimated 100-year service life (Figures 1 and 2 above). In addition, they were able to manufacture lateral stubs such that the street catch basin drainage could easily be tied into the main pipe.

2. Optimal Pipe Diameter for Hydraulic Performance

Determining the optimal pipe diameter to ensure hydraulic performance involves more than just selecting a size based on flow requirements.

Key considerations include factors such as flow velocity, capacity, and head loss. In addition to this, it’s essential to account for entrance loss and exit loss conditions, as these can significantly impact the overall hydraulic performance.

Entrance losses occur when water enters the pipe, typically due to abrupt transitions or changes in pipe geometry, while exit losses are associated with the water exiting the pipe, which may be influenced by outlet design, tailwater conditions, and other environmental factors.

The performance of a rehabilitated pipe is not solely determined by its diameter and Manning’s coefficient. Hydraulic behavior is also influenced by other critical factors, such as pipe roughness, slope, and the flow characteristics within the pipe.

Given the wide variations in Manning’s coefficients for different sliplining materials, it is essential to consult with the manufacturer or their representative to fully understand the range of available options and any potential variations.

For example, solid-wall high-density polyethylene (HDPE) pipe and glass reinforced pipe (GRP) typically have a standard Manning’s coefficient of 0.009, provided the materials are unaltered. However, materials such as Interior Open Profile Wall HDPE by ISCO Industries and Tunnel Liner Plate by Contech Engineered Solutions can exhibit Manning’s coefficients of approximately 0.035 or higher, depending on the specific product and its design features.

Therefore, it is highly recommended to consult the manufacturer’s specifications to ensure the correct selection for each project’s unique hydraulic requirements.

3. Environmental Considerations

In certain cases, the impact on aquatic life may also be a critical factor, especially if the pipe is part of a stormwater or wastewater system discharging into natural water bodies.

Therefore, the optimal diameter is determined not only by hydraulic calculations but also by an understanding of the broader environmental and operational context, which can affect the longevity and overall success of the rehabilitation project.

Of the various materials that are available, baffles for aquatic life such as salmon or trout can be accommodated. It is also possible to add roughening elements to certain pipelining materials.

4. Structural Integrity & Estimated Service Life

What were the failure modes that led to the degradation of the host pipe over time? Does the rehabilitated pipe meet the required structural standards to withstand live loads, dead loads, and groundwater pressures (ie. is the pipe standalone structural by itself or does it rely on the host pipe condition to support loads)?

Additionally, is the repair solution recognized within the industry as a short-term (25-year), mid-term (50-year), or long-term (100-plus years) fix? What is the anticipated service life of the rehabilitated pipe?

For stormwater or wastewater systems, what are the pH levels of the surrounding soil and water? Is there a risk of corrosion due to the presence of hydrogen sulfide or other corrosive environmental factors?

These questions are critical in determining the long-term performance and durability of the rehabilitation solution.

Bed load is another key factor in understanding/estimating the service life of a pipelining solution. Is it anticipated that the velocities in the stream can mobilize small/medium/large rocks frequently through the host pipe?

Engineers have so many tools that they can pull from when it comes to selecting a liner. Typically, the first step should include some level of host pipe inspection. Merely inspecting the inlet and outlet is not sufficient. It is recommended that the pipe be inspected thoroughly inside and outside.

If the pipe is A) too small or B) not safe for entry, it is recommended that a crawler or inspection/televising device is used to safely examine the inside of a pipe.

Check on the slopes and in the pavement for sinkholes or obvious failure areas caused by surrounding soils being washed out.

Sliplining Resources are Available

The good news is that there are abundant resources available to assist in selecting the appropriate lining solutions. Engineers and owners alike can easily access valuable information online through straightforward research.

A wealth of resources, including case studies, technical specifications, and industry guidelines, is readily available to support decision-making. Additionally, estimates for the service life of various lining solutions are widely accessible, allowing folks to make informed choices based on the projected longevity of the repair.