How to Improve Lateral Inspection Accuracy and Efficiency

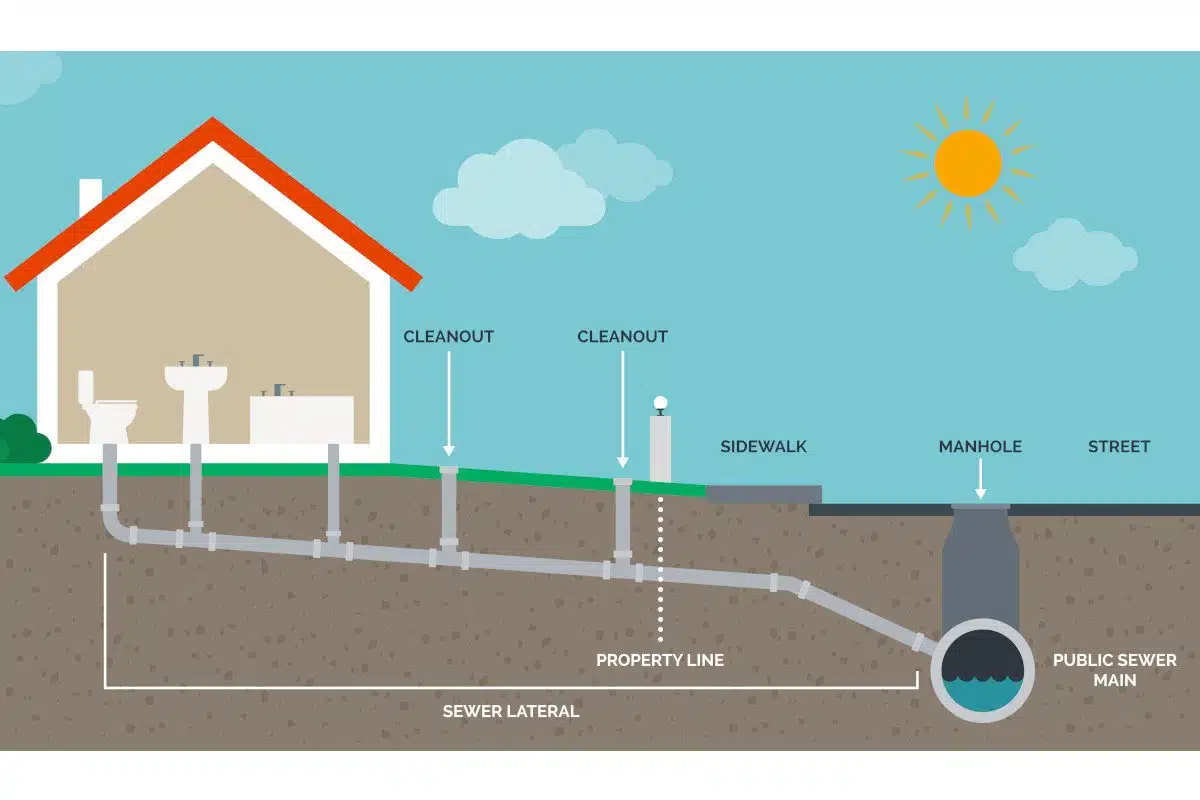

Lateral inspections often reveal the defects that drive rehabilitation decisions, yet they remain among the most difficult assets to inspect consistently. Tight connections, variable flow conditions, and limited visibility all present challenges in obtaining reliable assessments. Efficient and accurate lateral inspections begin with choosing equipment designed for precise positioning, controlled launching, and dependable video capture.

The quality of cameras on a lateral inspection system and the clarity of the video captured are key components to accurate assessments. A forward-facing HD mainline camera that observes both pipe conditions and the lateral launch point allows operators the best view of the pipe in order to confirm alignment. This reduces missed connections, failed launches, and unnecessary repositioning.

Self-leveling lateral cameras maintain consistent orientation for routine grading, while pan-and-tilt cameras provide greater viewing control for detailed assessments. In-pipe lens cleaning technology helps maintain visibility in debris-laden laterals and minimizes interruptions during inspections.

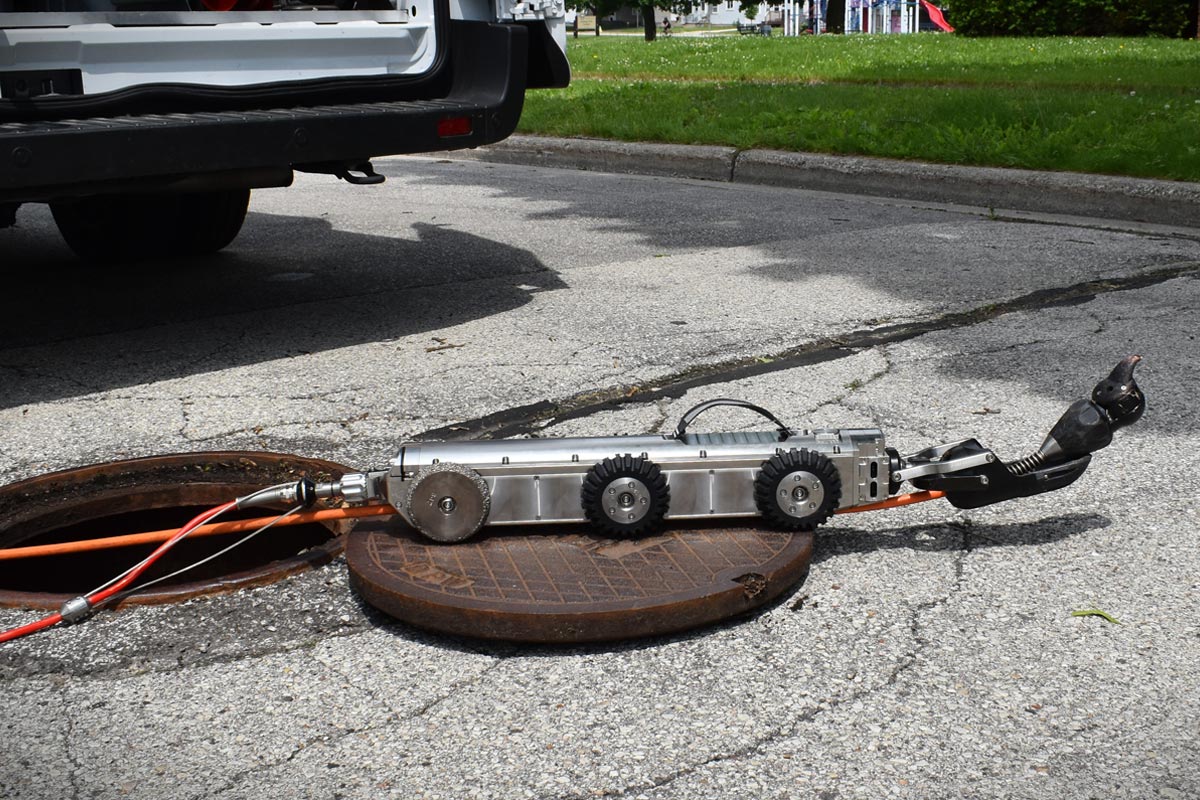

Launch hardware is also important to inspection success. A contoured, telescoping chute helps match the launch angle to pipe size and flow conditions. Launching with or against the flow at a 135-degree angle provides flexibility in active lines and improves entry into connections. Selecting the appropriate launch direction based on flow conditions and connection orientation increases first-pass success rates and reduces setup time.

System responsiveness directly impacts inspection speed and accuracy. Digital CANbus controllers deliver immediate crawler and camera movement, allowing operators to position precisely at each tap and navigate bends, offsets, and debris with confidence. Ergonomic joystick controls reduced operator fatigue during extended inspections.

Aries Industries LETS Sidewinder Lateral Inspection System includes all of the above features and components, ensuring crews can complete more laterals per shift while delivering consistent, usable inspection data.