How to Complete Risk-Informed Condition Assessment and Management of PCCP

Prestressed concrete cylinder pipe (PCCP) continues to play a critical role in major water transmission systems across North America. However, its unique failure mechanisms make proactive condition assessment essential.

Advanced electromagnetic inspection tools developed by PICA deliver high-resolution information about wire-breaks, loss of preload, and steel cylinder corrosion long before failure occurs. The true value of this data emerges when utilities understand how to interpret it. They must also integrate it into broader risk models and long-term planning strategies.

The first steps in assessing the condition of PCCP is data collection. This includes indirect assessments via desktop data analysis and direct condition assessment by utilizing inspection techniques such as electromagnetic tools. In addition, visual and sounding inspection via person-entry can be used where possible, or a combination of these methods is possible.

Desktop Analysis

Desktop analysis includes review of all relevant pipeline data (e.g., manufacturing data, performance history, environmental conditions, etc.), structural evaluation of pipes under the design, as well as maximum expected loads to evaluate susceptibility to damage. It also involves failure margin analysis to evaluate the sensitivity of the PCCP classes to distress in the form of broken prestressing wires using the proprietary Failure Risk Curves Technology developed by Simpson Gumpertz & Heger Inc. (SGH).

These reviews and analyses collectively inform where best to apply direct condition assessment tools.

Direct Assessment

Direct assessment data can be collected by a number of different methods including free-swimming and tethered tool deployments. This depends on the infrastructure and accessibility of the pipeline.

Electromagnetic tools such as PICA’s Near Field Testing (NFT) or Remote Field Testing (RFT) platforms are developed to capture high resolution data including the number and location of prestressing wire breaks and the condition of the steel cylinder. These data are necessary for engineering analysis to determine the failure risk and repair priorities of distressed pipe segments along the pipeline. Where person-entry is possible, internal visual and sounding inspections are performed to identify pipes with advanced stage of distress. Visual and sounding inspections can also help find anomalies that cannot be captured with high-resolution tools such as distress related to thrust, settlement, and joint issues.

Planning a direct condition assessment project involves multiple factors. These range from planning outages and dewatering, potential civil work, permitting, to repairs and re-commissioning of the pipeline. Depending on the size and criticality of the pipeline to be inspected, inspection schedules can span multiple years from planning to actual inspection and repairs. Proactive planning and periodic inspection schedules are important to ensure all stakeholders are onboard and ready to execute the inspection.

After planning the inspection, data collection can begin. Coordination between asset owners, service providers and engineers is important to maintain the project schedule. High resolutions electromagnetic tools are inline inspection tools developed to inspect long lengths of pipeline. They are also able to capture large amounts of data.

Evaluating Failure Risk

Upon completion of the data acquisition and analysis of electromagnetic signals to estimate the number and location of broken wires, the next step is to evaluate the failure risk and repair priority of each distressed pipe segment using Failure Risk Curves developed by SGH for the PCCP classes containing distressed pipes.

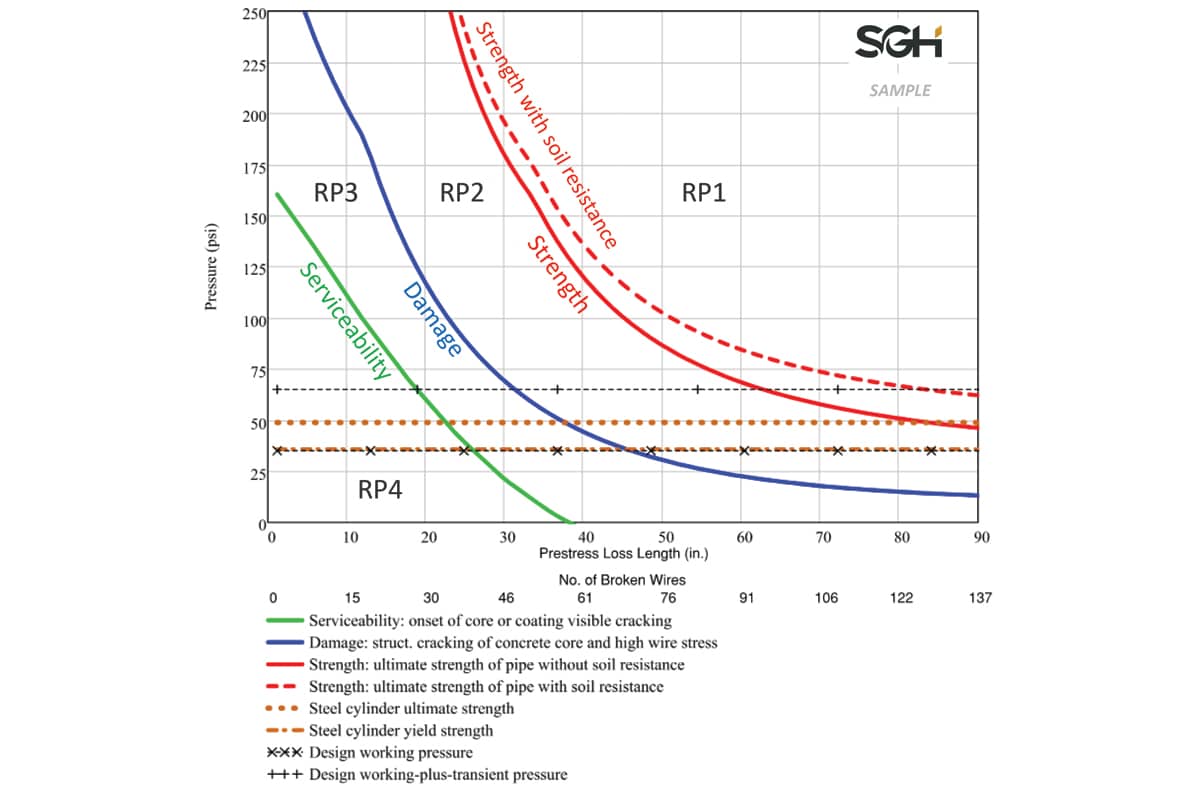

Failure risk curves are developed through a series of nonlinear finite element analysis of PCCP with varying number of broken wires. These models are subjected to the combined effects of earth load, self-weight, and internal pressure. The results are used to develop a relationship between the number of broken prestressing wires and internal pressure required to reach different limit states in the pipe, namely serviceability, damage and strength limit states.

These limit states divide the failure risk curve plots into repair priority (RP) zones RP1 through RP4 in the order of descending failure risk and repair priority. Additionally, the risk curves allow for evaluation of whether a PCCP class is expected to exhibit warning signs such as leakage prior to failure, or susceptible to sudden failure.

The failure risk and repair priority of a distressed pipe is determined by calculating and plotting the “effective” number of broken wires on the risk curves. The effective number of broken wires account for several uncertainties in the electromagnetic data, degraded condition of wires adjacent to broken wire zones, expected growth of wire breakage with time based on historical data, and potential interaction of multiple broken wire zones in a distressed pipe. The need for immediate, near-, mid-, and long-term repairs is evaluated based on where the effective number of broken wires and internal pressure combination falls within the risk curves. This also allows asset owners to optimize the use of resources available for a given shutdown.

Depending on the nature and extent of distress identified by the inspections, and feasibility of excavations, external inspection of selected pipes can be performed to verify the pipe condition. It can also help evaluate the mode and potential causes of wire breakage by a combination of field inspections and laboratory testing (e.g., petrographic analysis of mortar coating, soil corrosivity testing).

Assessment to Rehabilitation

The condition assessment process outlined above helps identify individual at-risk pipe segments. It allows for their local (joint to joint) rehabilitation without having to rehabilitate long stretches of the pipeline that also contain non-distressed pipes.

Over the last couple of decades, such localized PCCP rehabilitation methods, including internal carbon-fiber-reinforced polymer (CFRP) lining and external post-tensioning, have been developed and effectively used to maintain pipeline reliability.

As PCCP assets age and system demands increase, collaboration between inspection providers, engineers, and asset owners is more important than ever. High-quality data, interpreted within a structured engineering framework, offers a powerful path toward proactive, risk-informed, and sustainable pipeline management. This helps to maintain pipeline reliability.

By embracing these modern pipeline management techniques, utilities can confidently chart a course that protects their customers, budgets, and long-term infrastructure goals.

Kevin Weeks, is vice president of sales and marketing at PICA Corp. Murat Engindeniz, Ph.D, P.E., P.Eng., is a principal at Simpson Gumpertz & Heger Inc.