HDD Project Brings Clean Water to Frog Lake

In 2021, the Frog Lake First Nation secured federal funding from the Government of Canada to upgrade its water infrastructure. This was a vital investment to ensure safe, reliable, and clean water for the community’s projected needs over the next 20 years. The project involved building a new water treatment plant and installing a 1,100-m raw water intake pipeline from Frog Lake.

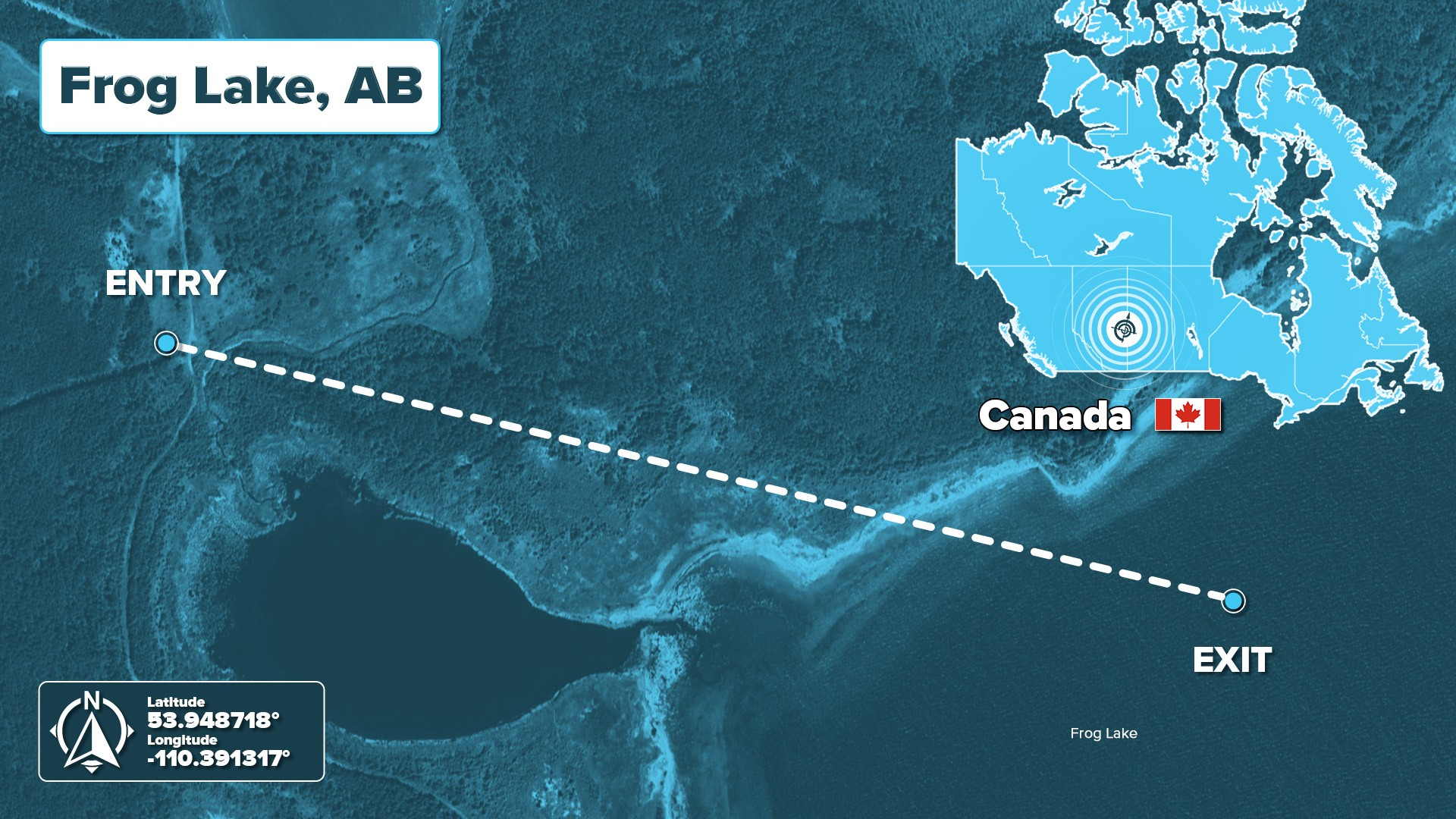

Frog Lake is located approximately 200 km northeast of Edmonton, near the Alberta-Saskatchewan border. It is on the ancestral and traditional lands of the Frog Lake First Nation, a Cree community deeply rooted in history and culture within Treaty 6 territory. Today, more than 3,000 residents call Frog Lake home.

Selecting the Right Construction Method

To build this shore-approach pipeline, BlueFox Engineering determined that horizontal directional drilling (HDD) was the most feasible construction method. Two-thirds of the pipeline alignment design is beneath the lake. This limited surface access for verification and demanded the highest level of downhole steering precision. The project was scheduled to be completed in the winter when the lake was frozen. This timing presented unique logistical, technical, and safety challenges.

The exit point in the lake required the construction of a narrow exit window through the ice. The pilot hole had to exit at the lakebed approximately 8 m below the frozen surface. The project was time-sensitive as there was a limited time frame that heavy equipment could operate on the ice-covered lake. Crews continuously monitored ice thickness to ensure safe working conditions.

A Collaborative Effort

By January 2025, preparations for constructing the HDD segment of the water intake pipeline were well underway. Arc Trenchless Solutions took on the primary contractor role of this portion of the project. This involved installing 45 m of 42-in. conductor surface casing at entry side. The final product line was a 12-in. HDPE pipe. Brothers HDD was the drilling contractor on this project and mobilized their 550,000 lbs. Vermeer D550 drill rig.

The HDD design has two vertical build sections designed at a 400-m radius. There was a minimum allowable bending radius of 230 m per 30 m (or a maximum “dogleg” of 7.47 degrees per 30 m).

Brownline was selected to conduct the downhole surveying of the pilot hole using their Drillguide Gyro Steering Tool (GST).

Accurate Surface Casing Mapping

The first challenge in drilling the pilot hole was obtaining a precise dataset of the 42-in. surface casing. Engineers recommend installing surface casing to maintain the integrity of the borehole. It helps reduce risk of ovalization near the surface at the entry point while drilling and minimize the potential for inadvertent returns near the entry pad.

The GST relies on inertial sensors in the form of gyroscopes and accelerometers to capture accurate positional and directional information. This enables the GST to independently and accurately map the surface casing without being susceptible to magnetic noise from the steel surface casing.

Navigating Beneath a Frozen Lake

One of the main reasons the team selected the GST is its ability to run independently without surface tracking. This unique stand-alone feature of the GST allowed the crew to accurately verify the alignment of the bore path in real-time. It ensured this without compromising the ice surface or disturbing the surrounding environment.

The unique geological conditions under the lake also posed a significant challenge. Typical geological investigations of lakebed formations include a mix of silts, clays, and occasional cobble zones. The presence of hard layers introduces risks that the drill head may deflect from the designed bore path.

The GST’s real-time data transmission of pitch, azimuth, and toolface information occurred at a data rate of 10 times per second. This enabled the crew to quickly and proactively identify and correct deviations. This approach ensured that the bore stayed within the stringent technical specifications, such as the minimum bend radius, throughout the pilot hole phase of operations.

Hitting the Target Under Ice

The 1.10-km pilot hole took two weeks of continuous 24-hour operation to complete. A 6-1/2-in. Wenzel mud motor paired with a 9-7/8-in. tri-cone bit was used. The annular pressure was closely monitored using the highly sensitive sensors on the GST. Pressures remained within nominal ranges and cleaning trips were promptly taken whenever a rise in pressure was detected. This ensured that the bore remained clear of cuttings and free from blockages.

The team took a GPS Track verification at approximately 50 m before the exit target. This ensured that the drill-head was within centimetre accuracy of the designed bore path. The results showed a 26-cm deviation on the azimuth plane (left-right) and a 48-cm deviation on the inclination plane (up-down) over a drilling distance of more than 1,000 m.

These results were well within the GST’s stated tolerance of ±70 cm over that distance. The crew made the required adjustments and successfully punched out at the designated target. Divers were able to retrieve the drill head and guide the bottom hole assembly to the frozen surface. This was the desired ending to a challenging pilot hole.

A Precise Feat with Lasting Impact

The successful completion of this project resulted in a lasting impact on the local community’s water infrastructure. The new water intake pipeline provides secure and sustainable water for generations to come. From a technical standpoint, the unique abilities of the gyro tool demonstrated the value it offers for challenging pilot holes of this magnitude. It met the demands of distance, depth, environmental sensitivity, and magnetic interference with centimeter accuracy all on its own.

This achievement was only possible thanks to the collaboration between all the teams that worked on this project. Each team contributed specialized expertise. Along with the input and support of the Frog Lake First Nation, they ensured that the work was completed with respect for environmental and cultural values.

Mohammed Alwazir is a project manager at Brownline Canada.

- Engineered HDPE Solutions for Trenchless & HDD Projects

- Microtunneling Short Course Owner Scholarship Program now Open

- IQuip Introduces the BOOST HDD Support Truck

- How to Maximize HDD Tooling Efficiency in Hard Rock

- Azuria Water Solutions Adds Waterline Renewal Technologies to its Roster

Next Up

2026 CUIIC Academy Spring Summit | March 3-5, 2026 | Mississauga, Ontario | Learn more