Ground Conditions

Soil conditions in this part of the state can range from cobble to sand to rock formations all within a 500-ft bore. So it takes a great deal of planning, patience and experience to complete underground installations in this part of the country, and that’s where Earth Energy comes in.

Earth Energy was formed in 1989 by Erv and Darrin Hoge. They began by placing drops for the phone company, which included plowing, trenching, splicing and a variety of underground operations. In 1993, the company expanded into larger utility installation projects and today the company specializes in providing HDD services for the installation of fiber optics, phone, power, gas and water and sewer lines. Earth Energy also provides HDD services to the petroleum and gas industries, along with remediation of hazardous waste sites.

River Project with Multiple Challenges

Earth Energy was contracted by United Water, the local potable water utility in the Boise area, to install a new 24-in. HDPE water main across the Boise River. The water main was being installed to provide a more reliable water source and line pressure to existing and new customers in the rural part of northeast Boise.

“Earth Energy has a long-term relationship with United Water and their prime contractors to provide directional drilling services on new large-diameter water mains and the smaller service lines to commercial and residential customers,” says Erv Hoge.

Prior to providing a bid for the project, Earth Energy conducted a series of site visits to determine the general layout of the area and met with the local utility companies to determine the location of existing underground facilities that may be within the proposed bore path. One of the primary utilities was an existing gravity sewer main crossing the river near the vicinity of the proposed bore.

Another critical issue was the location of the utility easement along existing residential homes, which limited the amount of room between the sewer line and private property. Once these boundaries were determined, Earth Energy could proceed in developing a running line and profile for the new water main.

The 640-ft bore would pass under the Boise River and a parallel stream, designated as a sensitive trout fishery, as well as a wetland area. Earth Energy was asked to maintain a minimum depth of 15 ft below the bottom of the stream and minimum setbacks were required away from the stream and river banks to prevent encroachment or damage to the wetlands and the sensitive flood plain area.

“Overall the terrain across the bore path is relatively flat except for a drop in elevation of approximately 6 ft within the stream banks and river,” says Hoge. “The entire area within a quarter mile of the bore was also within the floodplain of the river.”

Some of the challenges in completing this bore included maintaining the proper alignment within a limited utility corridor across the stream and river. In addition, the ground conditions varied between a loose gravel and cobble material to sand lenses and back to cemented cobble.

The bore began on the creek side with a setback of 150 ft to get to the desired depth of 27 ft below the river bottom and ended up on the river side 100 ft from the bank.

Earth Energy used its Vermeer D100x120 Navigator horizontal directional drill for this project — the newest addition to its fleet of six Vermeer drill rigs. The unit produces 100,000 lbs of pullback force and was fitted with a 6.5-in. single-roller type cone drill head for the pilot bore.

“The pilot was pretty difficult,” says Burke Williams, operations manager for Earth Energy. “Due to the cobble, it was a struggle just to keep our pitches within reason for the diameter pipe we were installing. Once we got into the more solid formation, the bore went smoothly until we exited and again we had trouble keeping our pitch in the loose material.”

To make matters worse, the pilot bore had to be completed with an arc to avoid pilings from a future bridge that was to be installed parallel to the bore path.

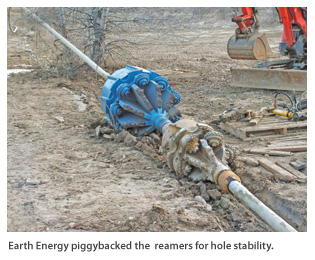

Once the pilot bore was completed, Earth Energy utilized a series of roller cone-rock reamers to pre-ream the borehole to a 36-in. diameter before installing the 24-in. HDPE pipe.

“We piggybacked the reamers,” says Hoge. “Once we completed a backream, we would use that same reamer to lead a larger-diameter reamer through the borehole. The piggyback procedure provided us with some stability inside the borehole considering the ground conditions.”

With each 6-in. increase in borehole size, additional challenges were created in maintaining the proper mud mixture to remove the drill cuttings and prevent the borehole from collapsing. Earth Energy constantly adjusted the bentonite mud mixture to maintain the borehole. The loose unconsolidated cobble material near the surface was the most difficult to maintain.

“The pullback was a piece of cake,” says Williams. “During the pullback, our pressure never exceeded 60,000 psi, considering we were pulling more than 53,000 lbs of pipe into place. The total project from pre-planning to completion took 42 working days.”

Planning Tools Invaluable

One of the advantages of using Vermeer equipment is the availability of Vermeer Bore Pilot and Atlas Bore Planner software to design the directional bore.

According to Hoge, the initial step in utilizing the bore software was to determine which directional drill would be used on the bore. Once the drill size is determined, a topographic surface is built with the software and the desired depths along the proposed route are input into the software program.

“The software designs the bore profile based on the allowable bend radius of the drill stem being used,” says Williams. “The computer will warn the user if the desired depths along the bore change too quickly for the drill stem in use.”

Once the bore was completed, the actual as-built depths were input into the software and a comparison showing design vs. the actual was graphically shown.

This project was one of Earth Energy’s more difficult due to the size of the pipe, the sensitive nature of the waterways and the variable conditions of the material to be bored. “We knew with proper planning and the right equipment we could complete the job and there really weren’t any surprises along the way,” say Hoge.

Greg Ehm is a technical writer in Des Moines, Iowa.