Geothermal Loop Installations

Emerging markets are always evolving. Some find long-term success and others fizzle out after a few years. One market is quietly growing and has a bright future as an alternative heating and cooling source in residential and commercial applications.

Ground source heat pumps — often referred to as geothermal systems — employ a technology that has been around for decades, but with rising energy costs and a more environmentally conscious public, the technology is experiencing significant growth. In fact, the ground source heat pump market has grown by 10 to 20 percent each of the past 10 years.

“A lot of people consider ground source heat pumps a new technology,” says Mike Kapps, with WaterFurnace International, located in Fort Wayne, Ind. “But it’s been around for a long time and is definitely a growing market.”

The first heat pump concept was developed by Lord Kelvin in 1857 and in the 1940s the technology was refined.

The 411 on Ground Source Heat Pumps

Ground source heat pumping is a process by which heat is moved into and out of the earth for the purpose of heating and cooling a building or dwelling, as well as providing hot water.

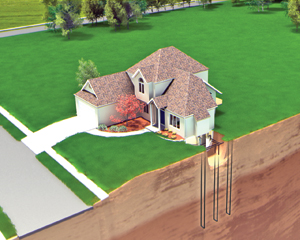

A typical ground source heat pump system features a heat pump, air distribution system (ducts, etc.), a hot water system and a series of long plastic pipes (loops) buried underground either vertically or horizontally. The heating and cooling needs of the structure dictate the cumulative amount of loop in the ground. The loops are filled with environmentally safe antifreeze and connected to the heat pump located inside the structure.

During the heating cycle, the system automatically pulls heat from the ground via the fluid in the loops and circulates it through the heat pump, which concentrates the heat and distributes it throughout the structure via duct work. At the same time, the antifreeze continuously cycles back through the loops, where it reheats, and the process repeats itself.

In hot weather when air conditioning is needed, the system reverses itself. Heat is extracted from the structure and is directed to the water heater or back into the ground where it can be stored for reuse during cold-weather months.

Getting in the Loop — Vertical or Horizontal

Typically, there are two main loop systems — horizontal and vertical closed-loop systems. Horizontal ground loop systems are used when adequate yard space is available. The rule of thumb is that 400 to 600 ft of pipe (out and back) per ton of load is required for a typical residential system. These loops (out and back) would be installed in a series of bores that range from 200 to 250 ft in length.

Contractors will encounter fewer rock formations with horizontal loops as the depth of installation typically ranges from 7 to 40 ft, depending on whether you’re stacking the loops or not. Stacking refers to installing one set of loops at a lower depth, such as 30 ft and another set directly above at a shallower depth, such as 15 ft. This installation method can allow the loops to be installed under buildings and driveways.

Vertical loops are ideal when yard space is insufficient to permit horizontal loops, when large heating and cooling loads are required and especially in retrofit applications where minimum disruption of the landscape is desired. However, vertical loops are generally more expensive to install and require a specialized piece of equipment to complete the required number of bores and the contractor will encounter varying soil formations.

With both installation methods, each hole will contain a single loop of polyethylene pipe that has a U-bend at the end. Once the pipe or loop is installed into the hole, it is sealed with a specially designed grout. The grout helps enhance thermal conductivity. The series of vertical or horizontal loops then connect to a supply line that feeds to the heat pump inside the structure.

The number of loops necessary to support a specific system is determined by the size and condition of the structure and the capacity of the ground formation to store energy.

Market Drivers

The popularity of ground source heat pumps among homeowners has been on the rise in recent years. According to Kapps, much of the growth can be attributed to energy savings and the “green” factor. Ground source heat pumps have been popular in new home construction, but that trend is changing based on the recent economic changes.

“I’ve watched the transition over the last few years go from new construction to retrofit,” says Kapps. “Ground source heat pumps were a great option for new construction and it was easier for the homeowner to justify the cost by rolling it into their overall mortgage. Now, the retrofit market has expanded and makes up about 70 percent of ground source heat pump sales compared to only 10 percent a few years ago.”

What’s behind the shift? New home sales are down and homeowners are living longer in existing homes rather than staying a few years and moving to other homes or upsizing. So investing in a ground source heat pump system makes sense, since they will be living in the home for a longer period of time. Current incentives are also driving the retrofit market.

Industry Challenges Create Opportunities

The steady growth of the ground source heat pump market has also created some challenges. Growth is good, but it can also be detrimental if the market grows too fast for the industry to keep up with the market’s expanding needs. That’s always on the forefront with the ground source heat pump industry players — not leaving anybody behind and delivering the tools that are needed.

This rapid growth of the market has created a shortage of experienced loop installers and many times a project must be delayed to accommodate the schedule of a loop installation contractor. The growth is creating opportunities for underground contractors to expand their service offering into the ground source heat pump market as a loop installer.

“There are regions of the United States where there’s a shortage, but then there are areas where if you need a residential loop installation contractor, you could get three or four contractors to quote a single project,” says Kapps.

On the commercial side — where vertical loops are more prevalent — there’s a larger pool of experienced commercial loop installation contractors.

“We are seeing a number of contractors flocking to the ground source heat pump installation market,” says John Clapp, with the International Ground Source Heat Pump Association, based in Stillwater, Okla. “Many of these individuals and companies have the best intentions, but just don’t have the right training and experience to install loops. It’s definitely a big hurdle right now.”

Look Before You Jump

With the opportunities that abound in the ground source heat pump market, it could be a significant new market for underground contractors. But with any new market, contractors need to research the pros and cons to their business. Just because this is a growing market, doesn’t mean it’s the right market for your company.

“I encourage contractors to visit with the companies already installing ground source heat pump loops,” says Ed Savage with Vermeer Corp. “They can share with you their experiences and that can provide valuable insight. They should also contact some of the local HVAC contractors in the area who are installing these systems. Ask them about the local and state requirements for loop installations (depth of bores, diameter of bores, grout, etc.) and explore the need for additional loop installation contractors.”

As with any venture, the business won’t grow on its own. There’s plenty of competition around, so dedicate time to market your services and build relationships with HVAC contractors and the local utility companies in your area.

Training to Be the Best

Training abounds within the industry to help contractors better understand how ground source heat pump systems work and how to properly install them. However, it all begins with industry standards and those have been developed by the International Ground Source Heat Pump Association (IGSHPA).

IGSHPA represents the ground source heat pump industry and creates installation practice standards for the industry. The standards are formulated by individuals and representatives from pipe manufacturers, grout manufacturers, equipment manufacturers and installation equipment manufacturers.

“Out of those standards came our training program,” says John Clapp with IGSHPA. “We developed and wrote standards for the industry and then used that information to create industry-wide training programs.”

IGSHPA offers an Accredited Installer Program. This three-day workshop covers all aspects of the ground source heat pump system installation process. Topics covered include the basics of designing the system, to loop installation, to installation of the mechanical equipment inside the residence or building.

A more focused training program — Accredited Drillers Training Program — covers all aspects of the loop installation process. It’s really designed for underground and water well drilling contractors, who are interested in installing vertical loops.

“Attending a training program creates a better education model for that contractor and helps them compete in the marketplace,” says Clapp. “It gives them all the tools necessary to know how to correctly design and install a ground source heat pump system, and better educated contractors lead to better installed systems and that helps improve the market as a whole.”

IGSHPA isn’t the only entity offering training to contractors. Heat pump manufacturers like WaterFurnace also offer training and support.

Clapp also points out that some states may also require the underground contractor to complete state-specific licensing requirements. Those requirements vary by state and even down to the county level in some states. So it’s important to communicate with your state Department of Natural Resources to completely understand the licensing and regulation process.

Training is only the beginning. Just because an underground contractor completes a training course and becomes certified, it doesn’t mean he/she has the experience to install a loop system — properly boring that hole takes some experience.

In Retrofits, Big Isn’t Always Better

There are a number of equipment options to install horizontal and vertical loops, ranging from well drilling rigs, to excavators and trenchers, to horizontal directional drills. However, horizontal directional drills have become the equipment of choice for horizontal installations, while well drilling rigs have been used exclusively in vertical well applications.

Now there are more compact and lighter drills on the market that allow contractors to access space-restricted spaces without causing significant damage to the existing landscape, says Savage.

Horizontal directional drilling manufacturers have answered the call for a more compact and versatile machine that can complete both vertical and horizontal loop installations.

Vermeer recently introduced a drill that is capable of drilling from 18- to 90-degree entry points — and anywhere in between. The unit is built for vertical and steep-angle geothermal loop installations; the D22x22FX Series II Navigator drill also functions as a horizontal directional drill (HDD) that can install horizontal loops and conventional utilities.

“For those with experience in horizontal directional drilling, they need to know that drilling a vertical hole requires a lot of patience,” says Savage. “It takes time to drill the pilot hole and keep the cuttings moving out — considering you may drill through clay, gravel and sand in one bore — while at the same time not allowing the tunnel walls to cave in. Then you need to get the loop into the bottom of the hole and ensure a solid seal with the grout. It’s not as easy as some think.”

So what’s all this pay? Well the industry experts say the average fee is anywhere from $5 to $10 per ft for drilling. In some cases that includes materials.

“It’s a competitive market,” says Kapps. “But for those companies that commit to and do quality work, there’s money to be made.”

Greg Ehm is a features writer for Two Rivers Marketing, Pella, Iowa.