Design Issues for HDD Projects Part 2

March 1, 2009

(This is Part II of a two-part series discussing HDD design issues. In February, Dr. Bennett addressed hydrofractures.)

(This is Part II of a two-part series discussing HDD design issues. In February, Dr. Bennett addressed hydrofractures.)Good engineering design demands all relevant issues be addressed in a balanced, rational way. To be successful, the design engineer needs the right analytical tools, judgment and experience to select appropriate input parameter values and people skills to listen to the concerns of regulatory and permitting staff and establish credibility with these staff by properly identifying and mitigating the risks — this in addition to having cost estimating and scheduling savvy.

In Part I, published in the February 2009 issue of Trenchless Technology, guidance on evaluation of hydrofracture risks was offered. Part II is a continuation that offers guidance on evaluation of settlement risks.

Settlements associated with trenchless installations include two types: large settlements and systematic settlements. Large settlements occur primarily as a result of loss of ground due to over-excavation caused by the inability to control adverse ground conditions or operator error. Large ground losses can lead to creation of voids or sinkholes above the bore. The risk of large settlements must be minimized through a comprehensive geotechnical investigation, selection of proper means and methods, use of ground improvement that can control the anticipated ground conditions and good workmanship by the contractor. The importance of a thorough geotechnical investigation and a skilled and experienced operator cannot be over-emphasized.

Systematic settlements associated with trenchless construction are primarily caused by the collapse of the overcut or annular space between the new pipe and excavation and to a lesser extent by elastic deformations of the soil ahead of the advancing bore. In HDD installations, the overcut allows drilling fluids to be injected, ensures good circulation, decreases pullback forces and facilitates cooling of cutting tools.

During or after pipe installation, soil surrounding the annulus may collapse or squeeze onto the pipe, filling the void created by excavation equipment. Soil collapse continues upward until the void appears at the surface as a trough. Systematic settlements can be controlled by selecting an appropriate depth for the installation, maintaining a reasonable radial overcut, keeping the annulus filled with drilling fluids and by grouting the annulus after pipe installation.

The practical observations of the approach described below to predict systematic settlements are:

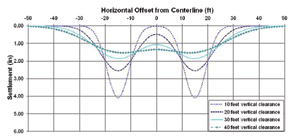

Systematic settlements decrease with distance above crown of pipe and with lateral distance from centerline of pipe.

Systematic settlements decrease as annular overcut decreases.

Systematic settlements decrease as soil consistency (density, stiffness) increases.

Systematic settlements decrease as bore diameter decreases.

To evaluate risks of excessive settlements that could damage roadways, utilities or other features, a thorough geotechnical investigation must be conducted and ground conditions and behavior must be documented. This approach minimizes the risk of unanticipated adverse ground conditions that could result in large settlements and claims by property owners. Conditions that pose potential problems include weak, compressible soils, poorly graded clean sands and gravel (especially combined with low blow counts) and high groundwater.

Existing surface and subsurface features that could be damaged by settlement must be identified, through a combination of site visits, researching as-built drawings and aerial photographs for other projects and utilities in the area, using the one-call system to identify subsurface utilities and potholing. Features that may be at risk from settlement include buildings, highways, railroads, levees, utilities, piles, piers, sound walls and culverts. Risk for a given feature depends primarily on ground clearance between the feature and bore, annular space, and condition, age and contractor workmanship.

The next step is to determine maximum allowable settlement for each feature. Maximum allowable settlement should be below that which would cause damage to the feature. Permitting restrictions may also limit maximum settlement tolerance for a feature. Technical specifications should establish maximum allowable settlements for critical features, through analysis and consultation with the owner of the utility or feature of concern. Suggested preliminary design criteria are presented elsewhere. Always consult the facility owner for specific allowable settlements. In addition, existing conditions at the time of the bore must be considered. For example, a large force main constructed in soft organic clay will almost certainly experience significant settlement over time, due to consolidation of the soft soils. The pipe may be unable to accommodate any additional settlement caused by a trenchless bore beneath it.

Settlements may be evaluated using methods adapted to trenchless construction by Bennett (1998), which were originally developed for soft ground tunnels by Schmidt (1969), Peck (1969) and Cording and Hansmire (1975). This approach models systematic settlements as an inverted normal probability curve, or settlement trough, with maximum settlements occurring directly above centerline of the bore and with settlements decreasing with distance from bore centerline. The unit volume (area) between the original ground line and predicted settlement trough is equal to the unit volume of soil assumed to be lost due to the bore annulus (and any assumed over-excavation). The approach has been corroborated by field measurements from completed projects. Empirical correlations are used to determine the settlement magnitude and distribution of settlement adjacent to the bore.

Total settlements from multiple bores, either side by side or stacked vertically, can be evaluated by summing settlements associated with each bore at any given vertical and horizontal offset, to capture the overlapping effects of both bores. However, the construction of the first bore will disturb and weaken adjacent soils, such that settlements associated with the second bore will be larger than estimated for a single bore.

Three factors can affect the percentage of annular volume translated to the surface: soil mass loosening, soil strength (arching) and drilling fluid/lubricant left in the annulus. Soil mass loosening occurs in dense soils when the soils dilate, or become less dense, as they collapse into the annular space around the pipe. Dilation increases the volume of soil and reduces volume of the settlement trough, and settlement at the surface. Conversely, a very loose soil may collapse and increase settlement trough volume. Settlement will be worsened if collapse occurs during drilling or reaming and the collapsing soil is conveyed from the bore hole via the drilling fluid.

Only a percentage of the annular space will be translated to the surface to result in settlement when arching occurs. The percentage of volume lost is affected by soil conditions, bore diameter and time. Soil consistency influences arching. Groundwater seeping toward the bore tends to undermine arching, especially over long time periods. For instance, a soft organic clay will likely squeeze quickly and completely surround the bore, whereas dense, angular sands and stiff clay remain stable and only partially collapse over a much longer period. Also, a larger bore diameter will reduce ability of soils to arch over the annulus and reduce the effect of soil strength. In addition, the longer a reamed bore remains open without a pipe installed the higher the risk that the bore will collapse. Finally, the volume of annulus that contributes to settlement can be reduced by the volume of drilling fluid that replaces the removed soil. In stable soil conditions, a well-designed drilling fluid should support an HDD bore limiting the volume of soil that will collapse into the annulus. In practice, the factors listed previously can be used to adjust the assumed soil volume loss used in calculations of estimated settlement, resulting in more accurate results.

If estimated settlement exceeds maximum settlement allowed for a feature, the design should be modified to reduce risk of damage, by deepening the alignment or reducing overcut. However, reducing overcut too much raises risks of loss of circulation, high pullback forces, steering difficulties and seizing of the pipe. Therefore, all aspects of design must be considered when addressing settlement risk to ensure a constructible project. Grouting the annular space can reduce settlement risk by preventing the annulus from fully collapsing on the pipe. Grouting should be initiated soon after completion of the bore. Grouting is especially useful at entry and exit locations where ground clearance is lowest. Grouting the annulus during pullback by mixing grout with drilling fluid is not recommended.

When the bore alignment or profile cannot be altered and an existing utility is at risk of damage from settlement, hardbacking or exposing a utility and physically supporting it, may be used to protect a utility. Grouting around or beneath the utility may be useful in soft or low density soils, before boring through the grouted zone. It is important to use a grout strength that is easily excavated with the drilling tools, yet has sufficient stability to support the utility. When none of these options are feasible, relocation of the utility may be required.

A pre-construction survey of critical crossing features and the surrounding area can be an effective tool to protect the owner and contractor from frivolous claims of damage that occurred before construction began.

Dr. David Bennett, Ph.D., P.E., is president of Bennett Trenchless Engineers, based in Folsom, Calif.