City of Baltimore Extends the Life of a 93-Year-Old Water Main

The Challenge: Replace or Rehabilitate?

How do you decide whether to spend $12 million replacing a 93-year-old water main or far less in targeted repairs? For the City of Baltimore, that question became urgent when a critical 36-in. cast iron transmission main beneath Clifton Park Golf Course began experiencing recurring joint leaks.

The pipeline, built in 1932 and cement-lined in 1982, remains a vital link in the City’s water distribution network. It still has many decades of remaining service life. While the City could continue repairing nuisance leaks as they surfaced, their frequency pointed to a deeper question:

Was the pipeline’s barrel beginning to fail due to age, or were the joints the primary source of trouble?

Answering that question was essential. The City needed a reliable, non-disruptive assessment to guide decisions about rehabilitation or full replacement. The goal was to minimize costs, service interruptions, and traffic control impacts for the surrounding community.

The Solution: Non-Invasive Assessment

To evaluate the condition of this transmission main, RJN deployed AVA, a non-invasive technology that measures the pipe’s dynamic response to controlled vibrations. This technology is powered by KenWave’s Dynamic Response Imaging (DRITM). Unlike traditional inspection methods, AVA allows data to be collected while the pipeline remains fully operational. It does not require the line to be taken out of service or equipment to be inserted inside.

RJN captured readings at 500-ft intervals along the main, using seven existing appurtenances and nine new potholes. This spacing achieved sub-pipe-stick resolution, providing a detailed view of wall thickness for each 6.6-ft pipe segment.

Through a series of controlled frequency tests, a wave generator excited the pipe. At the same time, sensors recorded its response. RJN’s team correlated those vibration patterns to the pipe’s wall stiffness. This mapping revealed changes in wall thickness and hoop stress, which is the circumferential stress acting around the pipe wall along the entire alignment.

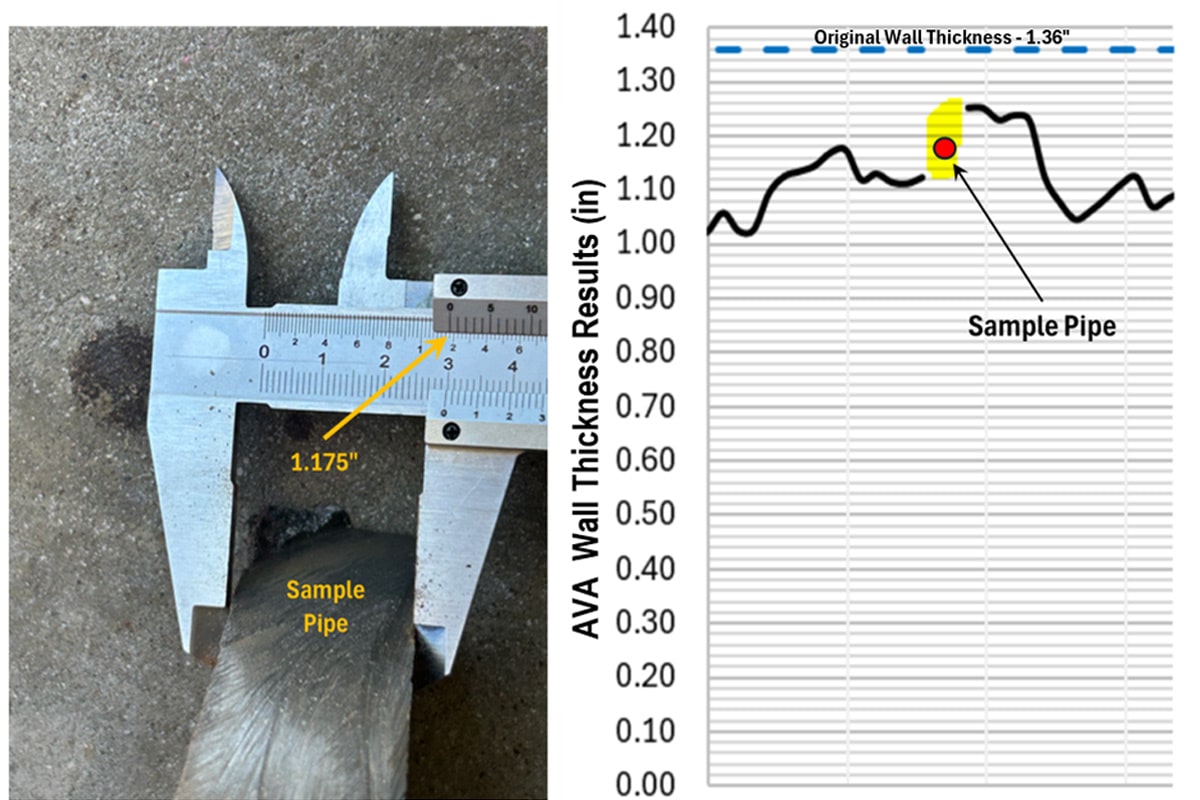

Engineering assumptions were based on 1927 AWWA cast iron standards, corresponding to the pipe’s installation era. They established an original wall thickness of 1.36 in. Given the pipeline’s 90 psi operating pressure and a safety factor of 2, meaning the pipe was assumed to safely withstand twice its expected load, the critical threshold was established at 0.162 in. of remaining wall thickness.

To validate the analysis, RJN compared the AVA results to a pipe segment removed during a 2023 hydrant installation. This sample showed a remaining wall thickness of 1.175 in. It closely aligned with the results and provided strong confidence in the accuracy of the assessment.

What the Data Revealed

The AVA analysis provided clear answers. Despite its age, the pipeline remains structurally strong. AVA testing revealed wall loss ranging from roughly 4 to 27 percent, with no segments showing distress levels that would indicate imminent failure. Approximately 15 percent of the pipeline fell into the good category (<10 percent wall loss). The remaining 85 percent showed moderate loss between 10 to 30 percent. None of the sections exceeded the 30 percent threshold that would warrant immediate action.

Understanding Long-Term Viability

These findings raised an important question: if the pipeline is sound, how much longer can it be expected to serve?

While precise remaining useful life prediction was not the goal of this study, RJN’s engineers modeled linear deterioration rates across all tested segments. This helped to better understand remaining structural capacity. The analysis indicated that the pipeline retains robust overall wall thickness. It should continue to provide reliable service well beyond its original design life under current operating conditions.

These figures are not literal forecasts but rather indicators of the barrel’s significant safety margin and remaining service life. The results confirmed that the cast iron pipeline retains ample wall thickness and strength to continue performing well beyond its original design life.

From a risk perspective, the primary operational concern is not catastrophic failure of the pipe wall. Instead, nuisance joint leaks contribute to maintenance costs and localized service disruptions. These joint-related issues can lead to traffic impacts and recurring field repairs. However, they do not represent a structural risk to the transmission main itself.

From Assessment to Action

With the barrel’s condition confirmed, RJN could present the City with rehabilitation alternatives. The AVA investigation not only verified the main’s structural integrity but also opened the door to a range of rehabilitation options. By verifying the barrel’s strength, RJN gave the City confidence to pursue targeted solutions. This prevented defaulting to full pipeline replacement.

Several feasible strategies were evaluated. These included internal joint seals, lining, and structural renewal methods. To support final design decisions, RJN recommended broadband electromagnetic (BEM) testing on segments with slightly higher wall loss. This would refine wall thickness estimates. Hydraulic modeling would confirm flow capacity if sliplining were to be pursued. When paired with the affordability of AVA testing, each rehabilitation option achieved significantly lower total investment savings. This is compared to the costs of full replacement and far fewer construction and traffic impacts.

AVA allowed the City to shift from a single, high-cost replacement plan to a suite of informed rehabilitation choices. This approach provided the utility with peace of mind for a critical asset, while maximizing value. The focus was on only impactful rehabilitation options.

Conclusion

RJN’s application of AVA technology reframed long-held assumptions about the condition of one of Baltimore’s most critical transmission mains. The results showed that the 93-year-old pipe remains structurally sound. Recurring maintenance issues stem from leaky joints rather than impending pipe failure.

This project marked more than a successful assessment. It represented a paradigm shift in how aging infrastructure can be managed. By applying modern, non-invasive diagnostics to legacy assets, the City demonstrated how innovation and pragmatism can coexist. With data guiding each decision, Baltimore turned a potential multimillion-dollar replacement into a targeted rehabilitation strategy. This preserves capacity, minimizes disruption, and upholds responsible stewardship of public funds.

In a broader sense, this outcome illustrates the evolution of infrastructure management. It marks a move from reactive maintenance to intelligent reinvestment. Through technology and insight, cities can extend the life of their buried assets, direct capital where it’s most effective, and sustain the systems that keep communities running for generations to come.

Carlos Espinosa, P.E., project manager at RJN Group Inc.

- How to Handle Dealing with a Railroad on Your Project

- How to Complete Risk-Informed Condition Assessment and Management of PCCP

- EnviroCure-Felt Technology Receives U.S. Patent

- Oatey Co. Promotes Kelsey McMillan to VP, Cherne Global

- Getting HDD Locator Calibration Right

Next Up

HDD Academy | February 19-20, 2026 | Scottsdale, Arizona | Learn more

2026 CUIIC Academy Spring Summit | March 3-5, 2026 | Mississauga, Ontario | Learn more