Cartridge Method Solves HDD Challenge Across Hunting Bayou

February 14, 2019

One of Houston’s major water transmission mains is a 42-in. line that begins at the East Water Purification Plant and continues north and west to provide water to a large distribution area in the northeast part of the City. Spanning nearly eight miles, the pre-stressed concrete cylinder pipe along Federal Rd., IH-10 East Freeway, and Loop 610 was constructed in the late 1960s and early 1970s. This 42-in. main has a history of leakage and needs repairs.For a 3,600-ft section along IH-10 East Freeway, between Baca Street and Centerwood Drive, there wasn’t a small-diameter water distribution line for local water customers. This 42-in. transmission main provided service for the businesses and tenants in this area. Eight active customers were connected to the 42-in. PCCP within this section, meters ranging in size from 1 to 6 in. Customers along this busy frontage road included a motel, a shopping center, a high-rise office building and a restaurant.

RELATED: Locating and Repairing Critical Leaks after Freezing Weather in Houston

The City of Houston recently detected an active leak on this aging 42-in. line within the project limits. Part of this line, which crosses Hunting Bayou above-grade, had been submerged in recent flooding and needed to be replaced. Two isolation valves on the 42-in. line also needed to be replaced. To perform this repair work, a long-term shutdown was desperately needed. Shutdown was not a possibility, because isolating the 42-in. would put these eight customers out of service.

Lockwood, Andrews & Newnam, Inc. (LAN), a national planning, engineering and program management firm, has served as the City of Houston’s technical advisor for its Surface Water Transmission Program (SWTP) for more than three decades. The City asked LAN to develop a solution to repair the 42-in. line without disrupting service to the eight customers. After evaluating various options, LAN engineers identified constructing a small diameter distribution main as the solution. A 12-in. water line could be connected to existing distribution lines and extended from Baca to Centerwood within a separate easement parallel to the existing 42-in. After placing the new 3,600-ft line in service and transferring the customers, a long-term shutdown of the 42-in. PCCP could be planned. However, constructing this 12-in. water line posed some daunting challenges.

Cartridge Method

One of the major challenges was a 600-ft crossing at Hunting Bayou, one of Houston’s major waterways that meanders through northeast Houston until it reaches Buffalo Bayou at the Houston Ship Channel. With active nearby businesses and driveways on either side of the bayou, the entry and exit sites for horizontal directional drilling had to be carefully placed. On the west side of the crossing, there was room for the drill rig and entry point set up. On the east side, there was much less space, and the full pipe string could not be laid out without blocking a busy intersection.

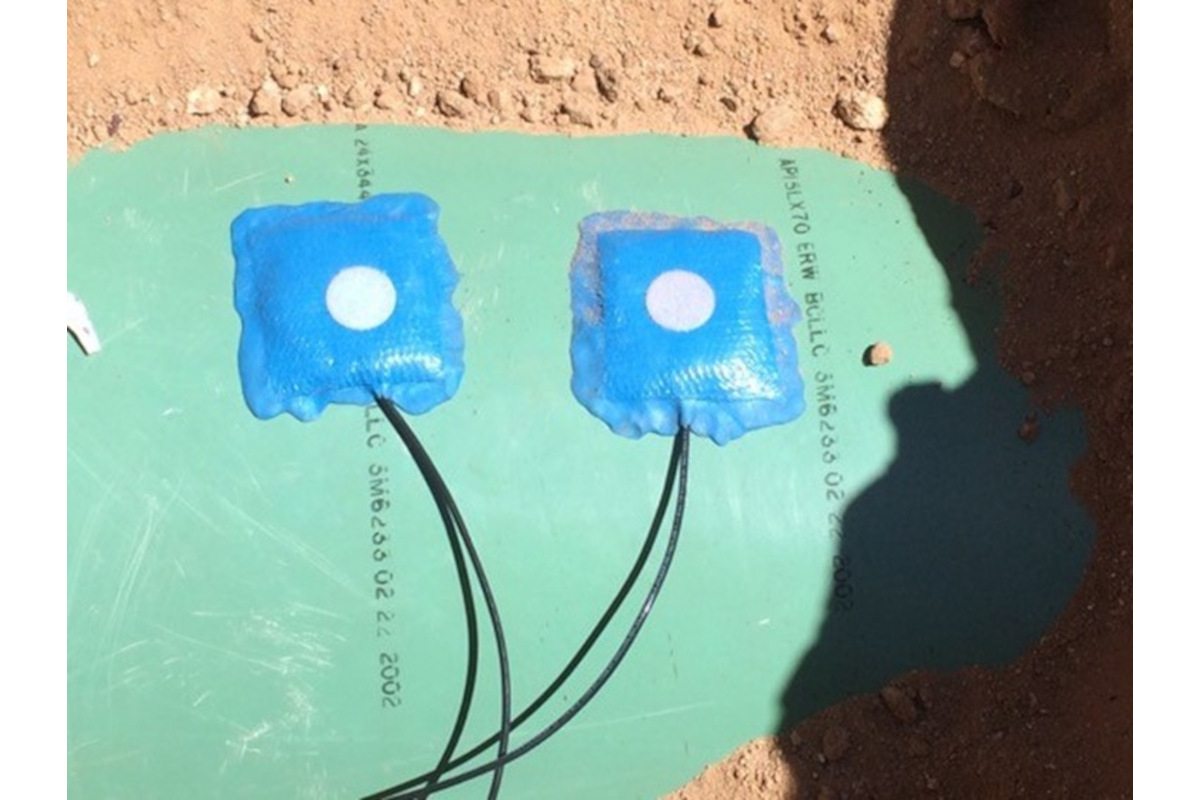

With fused pipe, each joint must be fused and allowed to cool, and the complete pipe string laid out prior to being pulled into the reamed hole. To avoid blocking the busy Centerwood intersection, the cartridge method of engaging each joint as the pipe was being pulled back provided the best solution. LAN recommended Certa-Lok C-900 RJIB (restrained joint integral bell) as the pipe material suited for this project.

The pipe can be assembled easily and is not weather-dependent. The RJIB joint has a bell and spigot configuration with a spline groove available up to 12-in. diameter. Once the joint is engaged, the spline can be inserted through the groove to lock the joint in place. Certa-Lok RJIB cannot be over-belled because the spline will ensure that the pipe is correctly engaged. The spline can be removed and pipe can be disassembled if needed. Once the joint is engaged, no cooling time is needed, and the pipe is ready to be installed right away.

RELATED: Large-Diameter Restrained-Joint PVC Pipe Helps Chicago Suburb Get Relief From Sewer Backups

Drilling and Reaming Process

The bore geometry consisted of an entry angle of 10 degrees and an exit angle of 12 degrees. The total horizontal length was 590 ft and the total depth was approximately 28 feet. The bore path crossed other utilities, including the existing 42-in. PCCP and an 8-in. gas line. The technical team from North American Specialty Products reviewed the bore geometry to ensure that the pipe bending radius and pull back forces would meet manufacturer’s installation criteria. The criteria required a maximum allowable tensile load of 60,000-lb force and minimum bending radius of 275 ft.

Grava LLC served as the general contractor, with R&A Road Boring, LLC, as the driller. The driller used a Vermeer D24x40 Series II Navigator machine with 24,000 lbs of thrust/pullback. After the pilot hole was drilled, the contractor used a butterfly cutter head. After two reaming passes, the pipe was ready to be pulled in.

Another challenge was managing traffic flow as the exit point was just behind the curb of the busy frontage road. The contractor set up a one-lane closure. The pipe joint assembly was done in the far right-hand lane, with wood blocks supporting the pipe and a small excavator lifting and moving each joint with a canvas strap.

The driller used a Vermeer D24x40 Series II Navigator machine with 24,000 lbs of thrust/pullback. After the pilot hole was drilled, the contractor used a butterfly cutter head.

Pull Back Process

To begin the pullback process, approximately 100 ft of pipe joints were pre-assembled and attached to the drill stem with the pulling head. As the driller began pulling the pipe in, the contractor engaged each new joint one-by-one. The challenge with cartridge method is the stop-start-stop process, in which the pipe has a greater risk of getting stuck in the dirt inside the hole. The driller, who had previous experience with this method, designed the slurry to be slippery to reduce the chances of the pipe getting stuck.

RELATED: HDD Under the Galveston Ship Channel

The forces experienced during the installation were in the range of 20,000-lb force. These conditions tested the machine close to its capacity. Despite all this, the pullback process went smoothly.

“The operator was very experienced and reamed the hole properly,” said Jose L. Rebollar Jr., of R&A Road Boring LLC. “We had a game plan to begin with and knew what we had to do. With bayou crossings like this, we have to keep moving.”

Within four hours, the complete pipe string was successfully pulled in on May 19, 2018. The project was tested, disinfected and placed into service. Once the customers were transferred over, substantial completion was issued on June 18, 2018. Future projects to repair the existing 42-in. line and replace the aerial crossing at Hunting Bayou are currently under way.

Christine Kirby, P.E., is a project manager at Lockwood, Andrews & Newnam Inc. (LAN).