A Brief History of Directional Drilling: The Birth and Development of the HDD Market

July 4, 2012

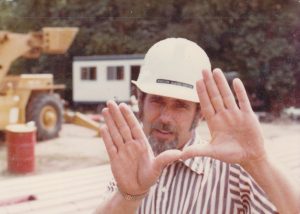

Cherrington’s first HDD rig build for a river crossing, shown here working on a series of river crossing projects for Dow Chemical in Louisiana in the early 1970s

Martin Cherrington does not have a Wikipedia page explaining how he is an inventor of the original equipment and process that eventually revolutionized an entire facet of construction. But when trying to encompass the history of horizontal directional drilling, it’s only appropriate to start with the man who many veterans of the trade have come to recognize as the father of HDD.

The Beginning

Horizontal directional drilling is an idea Cherrington first conjured up in the early 1960s when he was working for a utility installation company in Los Angeles. While out on a job, he witnessed another company doing some work nearby, using a hand-held air drill for a gas line installation. From that, Cherrington became familiar with the concept of guided drilling and wanted to take it a step further. He ended up taking it several steps further.

“My father was a contractor and I had an extremely broad background in civil construction,” Cherrington said. “I had wonderful education in different disciplines, so I was comfortable with welding, fabricating and mechanical-type things.”

By 1964 Cherrington had left the utility company and built his own drill rig to start his own gig with Titan Contractors Inc., where he began working under several contracts with the Sacramento Municipal Utility District (SMUD).

He described his drill rig as having a very basic, spindly, lightweight framework that supported the carriage that rotated the drill pipe. “It actually looked a lot like many of the HDD machines you see today, but slightly miniaturized, very light and skeleton-like,” he said.

Cherrington’s crew performed road boring for various utility companies in the Sacramento area and became known as a leading contractor for that type of work. Since the industry was nowhere near the development of electronic tracking, Cherrington’s crew used a technique he learned from the gas utility that used the hand-held air drill in Los Angeles. During the drilling, they would dig “potholes” at various intervals along the bore path, using depth to check the angle and direction of the drill head.

The River Crossing

HDD for river crossings has advanced since Cherrington first attempted it. Here, a rig is shown drilling underwater on a more recent job.

As far as road boring for basic utility installations, that was the beginning, even for Cherrington. His next task would mark another milestone in the drilling industry. In 1971, Cherrington was in Watsonville, Calif., doing some drilling for gas lines for the Pacific Gas & Electric Co. (PG&E). While he was in town, PG&E was intrigued by Cherrington’s new methods and asked him if he would take a look at another small problem they were facing. PG&E needed to cross the Pajaro River, approximately 500 ft, to install a 4-in. gas line and was wondering if Cherrington would be capable of drilling underneath the river.

According to Cherrington, this was “no man’s land” at the time because nobody had ever attempted this work. Cherrington faced several problems and at one point, even enlisting the help of some oil drilling methods. After basically experimenting with different approaches, they finally broke through to the other side, having worked on the project for nearly a month.

“Everyone claims that was the first river crossing ever done,” he said. “As far as I was concerned, because we were doing different kinds of jobs all the time, I thought that was it. It was just an odd job and I thought we’d never do that sort of thing again.”

Sure enough, news of Cherrington’s successful river crossing caught wind and he was soon contracted to do an even bigger river crossing in Louisiana. By 1979, Titan Contractors had completed a river crossing in Houston to install a 40-in. diameter pipeline – a job that, at the time, was considered the largest diameter crossing ever attempted.

“It took about 10 years after that first river crossing for [HDD] to really become a household name,” he said. Cherrington would eventually make his way back to Sacramento on a permanent basis, where he founded Cherrington Corp. in 1984, focusing on HDD for fiber-optic installations. But ultimately, that’s how horizontal directional drilling began.

Technology and Modernization

While its beginnings can be traced to Cherrington’s early work, the growth and modernization of the industry over the years is equally important and can be attributed to several developments. Similar to just about every other industry, technology has changed things considerably. With regards to HDD, some of the most important advancements have been in the areas of tracking and steering.

According to John English, president of Horizontal Technology Inc., developments in directional drilling have been directly related to the steering capabilities of drill rigs.

English, who started his career in the oil and gas industry and eventually started Horizontal Technology Inc. in 1997, said techniques in HDD advanced most when early work was done in rural areas with little congestion. He said in order for these methods to be applied in urban areas where the majority of construction was taking place, the industry needed to develop methods of surface tracking. He credits the introduction of magnetic steering tools as a turning point in the modernization of HDD.

In the late 1980s, Tensor, a company working to develop magnetic steering tools, created a steering technology using an artificial magnetic field that allowed a steering tool position to be determined in relation to a source, such as the drill head. For the first time, a contractor could verify the location of a drill below the ground.

“Once you could verify the location of a drill head, that changed everything,” English said. “You’re basically drilling with a compass below the ground. This opened up a big market for directional drilling. After that, it was a matter of the industry growing and wanting to get into that kind of work. The problem was that not a lot of people knew how to work in HDD because the process wasn’t well-known.”

English also addressed the environmental benefits HDD provided and said contrary to today, environmentalists were a big ally, mainly because they commended the use of HDD. He explained that environmentalists for example, preferred the method of drilling underneath a river rather than damaging it to trench across and so because of HDD, environmentally sensitive areas generally go undisturbed during a drilling project.

“There probably aren’t any tools in the world that have done more to save the environment than HDD,” he said. “The new generation of environmentalists tends to get HDD for certain applications mixed up with the oil and gas industry and don’t take into account the environmental benefits it actually has.”

The Bidding Process

On the business end, English talked about how the bidding process and the relationship between owners and contractors has shifted.

“Older bids would factor in everything that would need to be done in a given job and would also take into account everything that could go wrong,” he said. “Now everyone is just trying for the lowest bid.”

He also mentioned that because the owner of a pipeline, for instance, had such a close relationship with the drilling contractor, it allowed the owner to learn about HDD firsthand. English said that at the time, this was a great thing because it helped to educate people on directional drilling since it was still relatively unknown.

“At some point the industry grew so fast and you now have consultants communicating with the owner,” he said. “In some ways, the structure of the industry has taken a step backward. But in terms of overall improvements in HDD, methods are getting better, drills are larger and crews are trained better.”

Driving the Market

Since the initial HDD projects, many big companies have entered the market and taken directional drilling to a new level, both in terms of efficiency in the process and the size of projects. It wasn’t until several years after Cherrington’s first river crossing that other companies started to embrace the process.

Eric Skonberg, whose company Trenchless Engineering Corp. provides project management and consulting to HDD owners, engineers and contractors, discussed several of the major players who have driven the industry over the last 40 years and how the applications have shifted. Skonberg said early on, companies such as American Augers and InRock helped progress the industry in terms of providing a variety of services and equipment.

He also explained how many applications of HDD before the late 1980s were mostly in the oil and gas industry and that bore lengths and river crossings started with distances of at least 1,000 ft.

“The late 1980s and early 1990s was really when the small end of the HDD industry took off as Vermeer and Ditch Witch were coming into the market,” he said. “This was when fiber-optic cable installations began. It’s kind of interesting that the industry ended up growing down in installation size.

“The HDD market has also become more regional,” he said. “At the top end, companies like Laney, Michels, Southeast and Mears will pretty much go anywhere and take on any job.”

On the bidding side, Skonberg agreed with English that the majority of engineers and owners are much more knowledgeable about the process now than 20 or 30 years ago.

“I think it’s a much more competitive environment now,” he said. “Owners looked to the HDD contractor for all the engineering in the past, and didn’t have an appreciation for the difficulties that could occur. Now, they are fairly educated on the importance of ground conditions and other things related to engineering and planning for the work. As the technology has grown, so has the preparation of the projects before a contractor even gets involved.”

Cherrington’s Legacy

By the early 1990s, Cherrington held 13 patents on process and equipment he developed for the industry. While some of those have been sold and others have been acquired, Cherrington Corp. today still holds numerous patents on HDD design. Martin Cherrington reflected on how the trenchless industry has grown considering how most HDD practices evolved out of his original method.

“Along the way, as you’re out there working, you don’t really have a lot of time to dwell on things like that,” he said. “But I do reflect back now and look at the past and what has happened. I’ve seen a lot of changes and now, I see tremendous improvement in things like surveying and equipment.”

Cherrington also expressed his admiration of companies doing HDD today and the great strides that have been made with regards to the equipment. He said it has allowed for the completion of big jobs that are on a much different level than the early drilling jobs he was involved in.

“I think today, there are a lot of specialty companies out there making very efficient tools to help make this work possible,” he said. “That first job we did was to install 500 ft of 4- or 5-in. pipe. I just heard about a job that was to install 56-in. pipe that was 5,400 ft long.

“Look at the difference in size from what we did to now and look at how the equipment and tooling collectively, has allowed the industry to take a major jump like that. And what’s it going to be in the next 10 or 20 years?”

Andrew Farr is an assistant editor for Trenchless Technology.

Tags: Martin Cherrington