Akkerman Celebrates 30 Years of Microtunneling

In 1995, Akkerman Inc. reshaped trenchless construction in North America by becoming the first U.S. manufacturer to design and build slurry microtunneling systems domestically. At a time when all equipment came from Japan or Germany, this was more than a technical milestone—it was a declaration of intent.

Now, in 2025, Akkerman celebrates 30 years of slurry microtunneling innovation, partnership, and perseverance. This milestone reflects the vision of Maynard Akkerman, the breakthroughs that followed, and the contractors and employees who helped build a legacy.

As Maynard puts it, “Microtunneling didn’t just become part of our product line. It became part of our identity.”

A Vision Ahead of Its Time

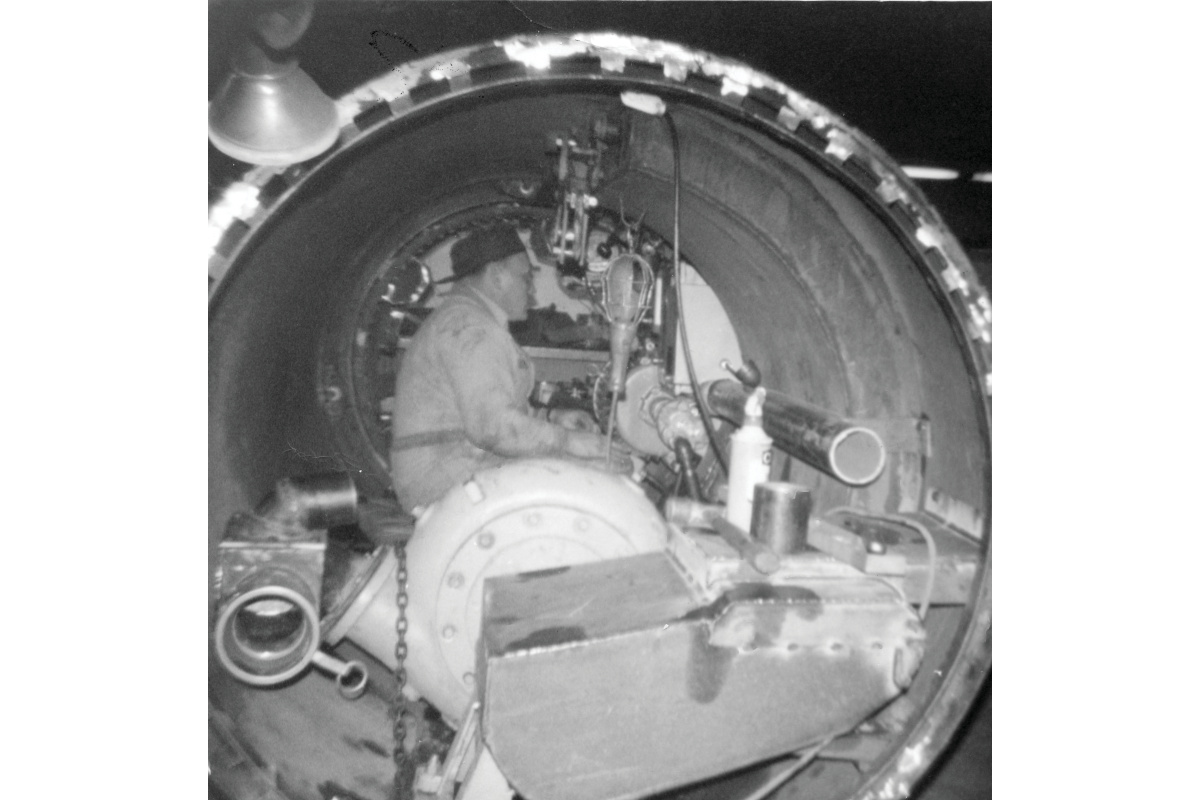

While most credit Japan with the development of slurry microtunneling in the mid-1970s, few know that Maynard’s father, D.H. Akkerman, began experimenting with the concept as early as 1966 in Brownsdale, Minnesota.

Inspired by slurry pipelines used in Minnesota’s Mesabi Iron Range, D.H. envisioned using slurry to transport spoils more efficiently in the TBMs he manufactured for his own construction company.

Though the prototype he built was never tested in the field, the vision behind it was prophetic. A reminder that innovation often starts in obscurity, years before the market is ready. Components of this 1966 R&D project remain preserved within the original two-stall shop located directly adjacent to the current Akkerman headquarters.

Skepticism, Then Momentum

Maynard recalls first encountering a Japanese slurry machine at a NUCA tradeshow in the 1980s. “I remember thinking, ‘Who wants to mess with all of these cables, wires and hoses?’” he laughs.

At the time, Maynard and his wife Robin were buying out the manufacturing side of the family business and selling off the construction arm. His focus was on building a strong foundation for Akkerman Inc., and microtunneling seemed like a risky distraction.

But customers didn’t let the idea rest.

“I have to give a lot of credit to Nada Pacific and Dave Cline at Pacific Boring,” Maynard says. “They struggled with another system in 1993 and pushed me hard to get involved.”

By the end of that year, Akkerman had expanded its engineering team and begun designing its first slurry microtunnel boring machine (MTBM). “We needed to do it,” Maynard recalls. “There was no turning back.”

No Pot of Gold — Just Grit

With a promise of a project in California and a lot of grit, Maynard and his team threw themselves into development. “We wanted to build the gold standard,” he says. “But there was no pot of gold to draw from.”

The ambition was ahead of its time. Maynard envisioned real-time system diagnostics and autonomation — tracking pressures, flow rates, and cutterhead performance. “This was 1993 — Al Gore didn’t even have the internet up and running yet,” he says.

While the tech wasn’t ready for that level of autonomy, the machine they built was rugged, operator-focused and reliable.

Breaking New Ground in Pleasant Hill

In 1995, their work paid off when Nada Pacific took delivery of the first Akkerman microtunneling system for a project in Pleasant Hill, California.

Pleasant Hill was undergoing major downtown infrastructure upgrades when Akkerman’s first SL52.5 MTBM was deployed. For Maynard, it was more than a jobsite — it was the place where American-made slurry microtunneling technology broke ground.

“Our first project was full of learning opportunities,” he says. “But it was a success. I’ll never forget it.”

Field-Proven and Battle-Tested

By 1998, Akkerman machines had proven their mettle. Elmore Pipejacking used the second system on a tough job in Las Vegas, tunneling through dense caliche, a cemented soil that punishes equipment.

“That project confirmed our machines could handle the toughest conditions,” Maynard notes.

Meanwhile, Nada Pacific delivered an award-winning performance on the South Orinda Sewer Improvement Project, installing over 8,000 ft of 36-in. sewer pipe. The project earned Trenchless Technology’s 1998 New Installation Project of the Year.

“Two major wins in one year—in hard ground and in recognition — validated everything we’d been working toward,” says Maynard.

Built for American Ground

As microtunneling grew across North America, Akkerman realized a key truth: what works in Asia or Europe doesn’t always work here.

“Our ground is brutal,” Maynard says. “Glacial till, boulders, mixed faces — you need brute strength, not finesse.”

This insight led to the SL60C, built for Super Excavators Inc. to tackle a challenging project in Marysville, Ohio. With a 250-horsepower electric motor, the machine marked a shift in design philosophy.

“That’s when we took the Harley-Davidson approach,” Maynard says. “Build it tough. Don’t overcomplicate it.”

The SL60C’s success set a new standard. Future MTBMs followed its design — optimized for torque, durability, and raw power.

Navigating the Curves

One of the major advancements in recent years has been in guidance systems. Traditional laser-based systems suffer from refraction — distortion caused by air movement in tunnels — which could throw off alignment, especially on long drives.

“Back in the 1970s, I’d watch the laser beam actually bend when ventilation turned on,” Maynard says. “That was always a limitation.”

While curved tunneling and total station systems became common in Europe and Asia by the 1990s, their accuracy and recalibration demands didn’t meet Maynard’s standards. “We wanted real-time accuracy without constant downtime,” he explains.

That challenge sparked a whiteboard session that led to the Akkerman AZ-100 Total Guidance System. The concept: maintain fixed-distance laser projection from a theodolite, which continuously references azimuth survey points in the shaft.

The result? A system that delivers precise, real-time positioning without the recalibration headaches—ideal for North America’s longer, more complex alignments. Today, multiple successes have been achieved using this approach including 2,000-plus lf complex curved alignments and NASTT’s Innovative Product of the Year Award.

From Small Tunnels to Giants

A common misconception is that microtunneling just means “small tunneling.” But that idea is outdated. “These machines can hit 10-ft diameter now,” Maynard says. “They’re remote-controlled rock goblins that can snake through deep geological layers with surgical precision.”

Whether it’s compact bores or massive sewer interceptors, modern slurry MTBMs can handle it all — and Akkerman machines have evolved to match.

A Family Legacy and the Future

When asked if he’d do it all again, Maynard pauses. “Yes,” he says, “but I’m glad I don’t have to.” With his son Justin leading daily operations, a trusted leadership team, and a deep bench of expert employees, Maynard feels confident about what’s ahead.

“It’s like the space program,” he reflects. “We pushed design limits for microtunneling, but those advances continue to ripple across all our product lines and make them better.”

Editor’s Note

This piece includes the final interview with Maynard Akkerman, as he passed away during production of the August issue of Trenchless Technology magazine. His legacy and passion for trenchless innovation live on through his words, leadership, and the company he helped build. We extend our gratitude to Maynard for sharing his time and wisdom.

Jason Holden is vice president and CRO at Akkerman Inc.

Latest Posts

- Spotless Sewer Lines Play a Key Role in Lining Success

- How to Develop a Cost-Benefit Analysis for Pipeline Rehabilitation vs. Replacement

- How to Apply ASCE MOP 145 to Gravity Lining Projects

- How to Prepare and Trowel-Apply for a Manhole Rehab Project

- Melfred Borzall’s Tri-Con™ System: Faster Changeovers. Stronger Connections. Built for the Realities of HDD.