2025 Trenchless Technology New Installation Project of the Year Honorable Mention

Nose Creek Sanitary Trunk Phase B – Contract 4

Ward and Burke Microtunnelling Ltd. played an integral role in the completion of the City of Calgary’s Nose Creek Sanitary Sewer Trunk (NCSST) project.

Project Background

The NCSST project involves the twinning of existing sanitary sewer trunk that runs from the Bow River, north beyond Beddington Trail N.E. This extension more than doubles the sanitary sewer capacity. It is required to accommodate future development and population growth in north Calgary.

For its part, Ward and Burke was tasked with building three caisson shafts. They installed 1.5 km of 1,650-mm ID HDPE lined reinforced concrete pipe (RCP) via microtunneling. They also installed 255 m of 1,500-mm HDPE lined RCP via microtunneling and 500 m of 1,650-mm FRP pipe via the open-cut method. Additionally, they constructed permanent works chambers and one live sewer tie-in.

To safely launch and retrieve the Herrenknecht microtunnel boring machine (MTBM), Ward and Burke designed and constructed a 9.2-m ID concrete caisson launch shaft. They built a 6-m ID concrete caisson reception shaft and a 5-m ID concrete caisson reception shaft. The launch shaft was designed with heavily reinforced sections behind the jacking frame. This was to resist jacking forces induced during microtunneling operations. All three shafts were sunk in clay on top of claystone.

The NCSST project is exceptional in the fact that it broke the record for the longest single microtunnel drive completed to date in North America. Ward and Burke launched the first drive on the project on May 22, 2024, and broke through the reception shaft on Sept. 29, 2024. The single drive was 1.5-km long. It featured four horizontal curves ranging from 700-m to 1.750-m radius.

The 1.5-km tunnel was constructed in ground conditions ranging from stiff clay/weak claystone to 20 MPa Sandstone. The entire alignment was under the water table.

Long Distance Microtunneling

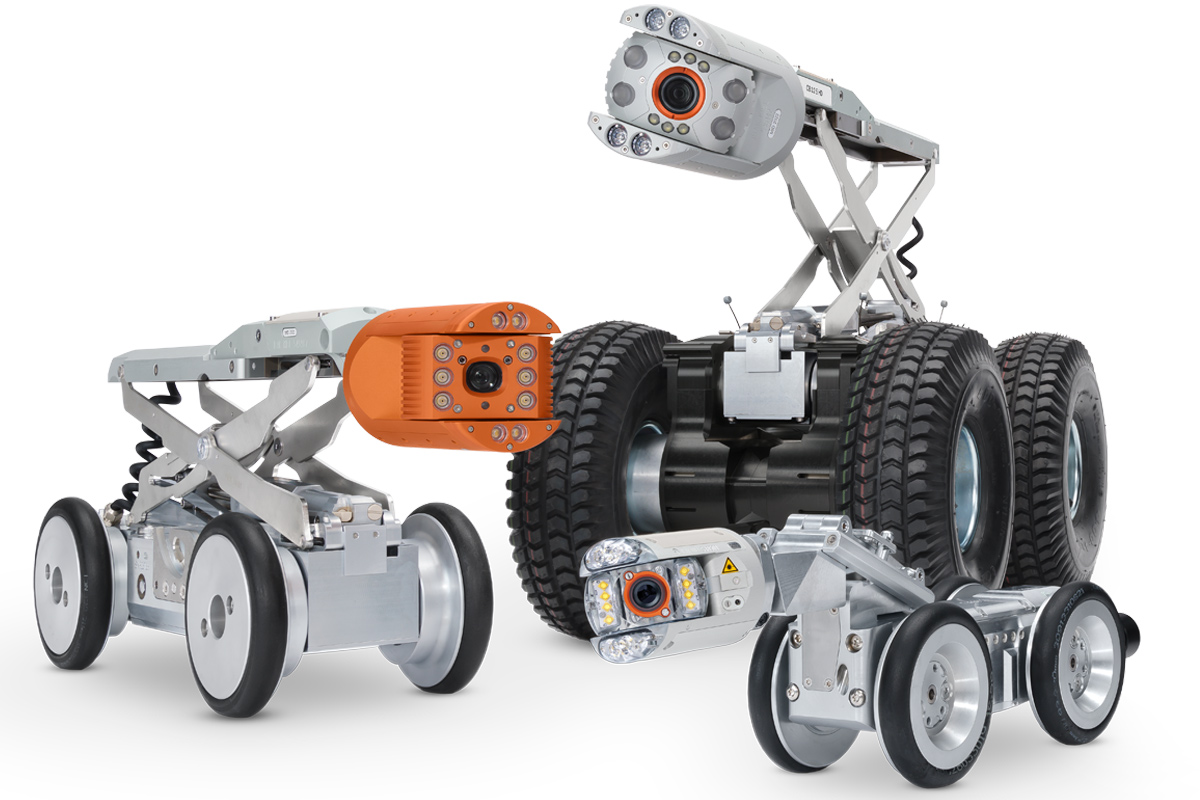

A Herrenknecht AVN 1500 with an upskin kit was used to construct the 1,650-mm ID HDPE lined RCP tunnel. The mixed face cutting head was fitted to the MTBM.

What’s even more remarkable about this drive is that although three intermediate jacking stations (IJS) were used, none of them needed to be engaged. The full drive was completed from the jacking frame in the launch shaft. It broke through at the reception with only 400 T force on the jacking frame.

This drive further promotes the capabilities of long distance microtunneling. This success is due to the correct tunneling equipment, lubrication systems, and pump setups. Most importantly, a competent and experienced crew played a vital role.

The same Herrenknecht AVN1500 base machine was used to construct the 1,500-mm HDPE lined RCP tunnel. The 1,500-mm siphon included two vertical curves. It launched downhill with a vertical curve (Radius = 1,000 m) and then crossed under a CPKC line and Nose Creek before curving back up with a radius of 720 m to reach the reception.

Why Project Is Outstanding

The NCSST project is exceptional in the fact that it broke the record for the longest single microtunnel drive completed to date in North America. The single drive was 1.5km long featuring four horizontal curves ranging from 700-m to 1,750-m radius.

The 1.5-km tunnel was constructed in ground conditions ranging from stiff clay/weak claystone to 20 MPa Sandstone. The entire alignment was under the water table.

What’s even more remarkable about this drive is that although three intermediate jacking stations were used, none of them needed to be engaged. The full drive was completed from the jacking frame in the launch shaft, breaking through at the reception with only 400 T force on the jacking frame (22 percent capacity of the frame).

This drive further promotes the capabilities of long distance microtunneling with the correct tunneling equipment, lubrication systems, pump setups etc. and most importantly a competent and experienced crew.

Project Details

PROJECT OWNER: The City of Calgary

ENGINEER: Jacobs

CONTARCTOR: Ward & Burke Microtunnelling Ltd.

SUPPLIERS & MANUFACTURERS: Herrenknecht, Precon Manufacturing

VALUE OF TRENCHLESS PROJECT (US$): $18,521,000

- How to Maximize HDD Tooling Efficiency in Hard Rock

- Azuria Water Solutions Adds Waterline Renewal Technologies to its Roster

- Puris, Per Aarsleff Partner to Strengthen Lateral Rehab in Canada

- Vortex Companies Rebrands Grout Line to Maverick Grouts

- Vermeer Unveils VXT400, VXT500 Vacuum Excavators

Next Up

2026 CUIIC Academy Spring Summit | March 3-5, 2026 | Mississauga, Ontario | Learn more