2025 Trenchless Technology New Installation Project of the Year

Champlain Hudson Power Express (CHPE) Terrestrial Project – Trenchless Crossings

Getting clean energy to New York City is not an easy undertaking. This is evidenced by the colossal amount of work undertaken as part of the Champlain Hudson Power Express project.

The project – nearing final completion in 2026 – was announced in 2010 by Transmission Developers Inc., a Blackstone Portfolio Company. Shovels didn’t break ground until 2022 due in part to complex permitting and regulatory approval.

The focus of Champlain Hudson Power Express (CHPE) is a generational infrastructure project. It will deliver up to 1,250 megawatts of renewable hydropower from Canada to New York City via a fully buried transmission line.

Once operational in 2026, CHPE will supply enough energy to power over 1 million homes. It supports New York’s Climate Leadership and Community Protection Act, and its goal of 70 percent renewable energy by 2030.

After years of planning, design, and working to gain regulatory approval a 339-mile alignment was put forth. This work includes three sperate contracts. A marine contract that involved installation of approximately 192 miles submerged in Lake Champlain and the Hudson River. A 147-mile terrestrial contract. And a contract to build the converter station in Astoria, Queens.

Since its inception the high voltage direct current (HVDC) transmission system was planned to principally run underground. This minimizes the impact on local communities. Looking at a map, it’s clear to see that this requires a considerable amount of trenchless construction.

CHPE Terrestrial Project

The Terrestrial Project corridor is a mix of public infrastructure, sensitive environmental zones and private land. All told, approximately 420,000 ft of high-density polyethylene (HDPE) and polyvinyl chloride (PVC) conduits were installed via trenchless methods. Work that required more than 300 horizontal directional drilled (HDD) crossings across 15 segments.

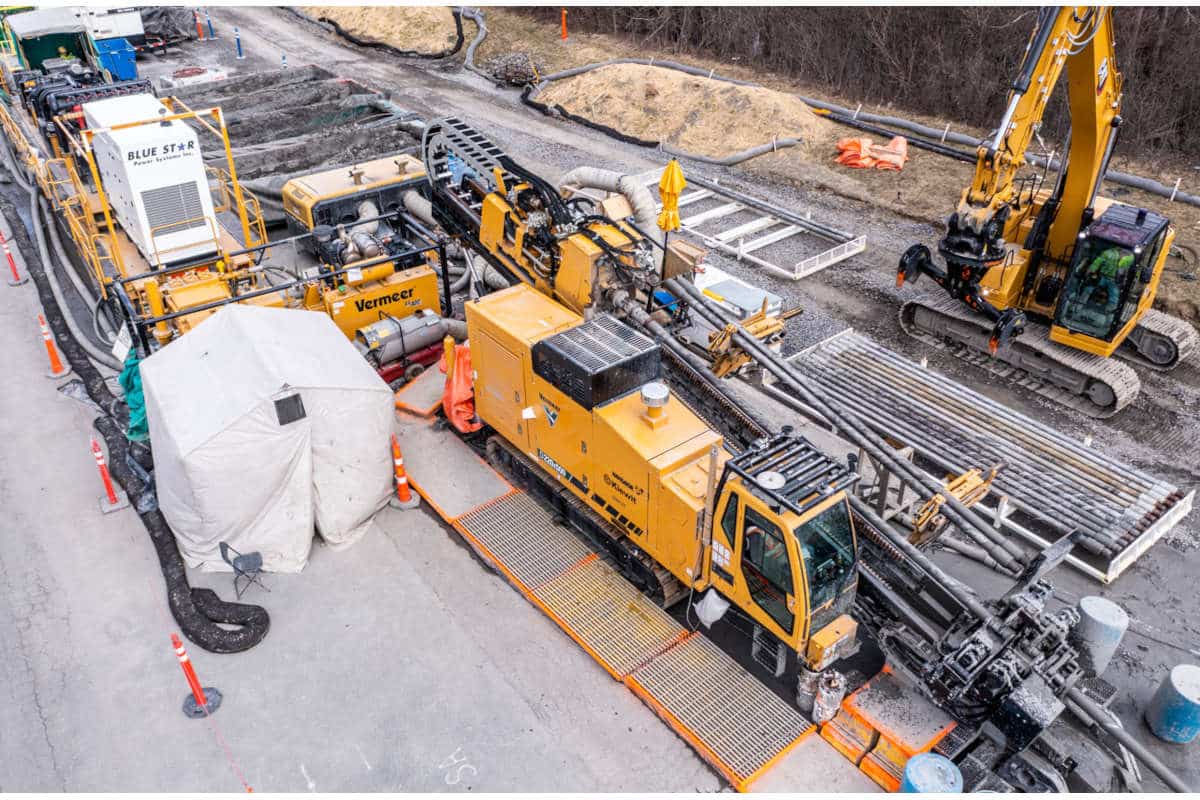

The work involved several challenging crossings, complex geotechnical conditions and a new pipe technology for HDD. It also required close collaboration beyond the scope of a typical trenchless project. Kiewit served as the lead designer and general contractor and managed four HDD subcontractors, as well as four subconsultants.

For all these reasons, the 2025 Trenchless Technology New Installation Project of the Year is the Champlain Hudson Power Express Terrestrial Project – Trenchless Crossings.

“From my perspective, the CHPE project required a level of collaboration that’s rare in the trenchless industry. The sheer scale and fluid nature of the scope demanded constant coordination; not just between the prime contractor and subs, but across multiple contractors, vendors, and third-party service providers,” says Phill Perron, vice president project development and delivery, The Crossing Group. “CHPE wasn’t just a technical feat, it was a logistical and cultural one. The project succeeded because competitive companies chose to act like a unified team.”

Terrestrial Team Assemble

The terrestrial route was divided into five areas and 15 construction segments. Kiewit performed more than 92,000 ft of HDD and managed four trenchless subcontractors — Aaron Enterprises, Haugland Group, HDD Company/The Crossing Group and Michels. The project team’s mission: maintain quality and consistency across a diverse and challenging alignment.

Each HDD location consisted of two parallel bores. One bore contained a 10-in. DR-9 HDPE or 8-in. DR-17 FPVC conduit bundled with a 3-in. DR-9 HDPE Conduit. The other bore contained one 8-in. FPVC or 10-in. HDPE conduit.

Early desktop designs called for approximately 132 bores, according to Kiewit trenchless manager Matt Roberts. He adds that after getting more detailed information, like wetland mapping and finalized easement agreements with third party stakeholders that number grew.

“The overall coordination when we looked at the job originally, we looked at everything linearly going from the north to the south and we broke the job early on into five areas and segments [within those areas.],” says Roberts.

Major third parties on the project are NYDOT (Areas 1 and 4) and two railroads (Areas 2 and 3). Area 5 comprised several third-party entities as this work took place in New York City.

This meant easements and access drove much of the project timeline and workflow as opposed to working in a straight linear fashion from Area 1 to Area 5.

PROJECT DETAILS

PROJECT OWNER: Transmission Developers Inc.

ENGINEERS: Kiewit Engineering Group (lead consultant); Brierley Associates, CHA, J.D. Hair & Associates, Kilduff and Tetra Tech (subconsultants)

CONTRACTORS: Kiewit (general contractor); Aaron Enterprises, Haugland Group, HDD Company/The Crossing Group and Michels Trenchless (subcontractors); and Plastic Pipe Technologies (fusion subcontractor)

SUPPLIERS & MANUFACTURERS: Brownline, Inrock, Prime Horizontal, Radian and Vector Magnetics (HDD navigation); Permalok (steel casing pipe); Ferguson and ISCO (HDPE); Underground Solutions (FPVC); and American Augers and Vermeer (drill rigs)

TRENCHLESS VALUE: $283,800,000

“We did predominantly all our self-perform work in Area 3 Segments 8 and 9. Others did work in Area 3 also. Area 5 was pretty much all Michels in the city,” says Roberts. “Area 4 in Rockland County was a mixture of The Crossing Group. We did have Michels do some work in that part of the job and Haugland. The Crossing Group did most of the work in Area 2. Aaron Enterprises did all the work in Area 1 and some in Area 2.”

Workflow was determined by finding the right crew to complete the work as easements and access became available. This required the contractors — who typically compete for work — to be flexible and collaborative in completing the work.

“There were multiple contractors completing an extensive trenchless scope of work. We were all doing what we were good at,” says Michels Trenchless president Matt Smith. “The Crossing Group did a tremendous amount of crossings–some easy and some hard. Michels focused on the more technically challenging crossing, and we were there as a resource for all of the crossings.”

Complex Geology

“Someone pointed out to me that this is some of the most technically challenging ground in the country,” says Roberts. “You get respect for that when you do the work.”

The project traversed varied geological formations including glacial till, fractured shale, volcanic ash, and unpredictable urban fill. Knowing this going in was one of the many reasons for the project’s overall success.

Kiewit and TDI instituted a robust geological investigation to help keep pricing stable. It also reduced uncertainty and risk on the job.

“We homed in on a robust geotechnical investigation in the design phase because we knew that we had a huge risk of varying site conditions potentially,” says Roberts. “We knew that we needed to get an adequate geotechnical investigation, and the owner realized it early on too.”

This meant taking sample cores at minimum at the entry and exit side of each HDD and then every 400 to 500 ft along the bore path. Additionally, the samples had to extend about 20 ft deeper than where the maximum depth of the bore was planned to be.

“Spending that money early on was really good because we had very few surprises,” says Roberts. “You still get some changes, the occasional boulders or what not, but it certainly gave us some more certainty.”

One of those technically complex HDD crossings – through bedrock – took place in Area 5.

East River HDD

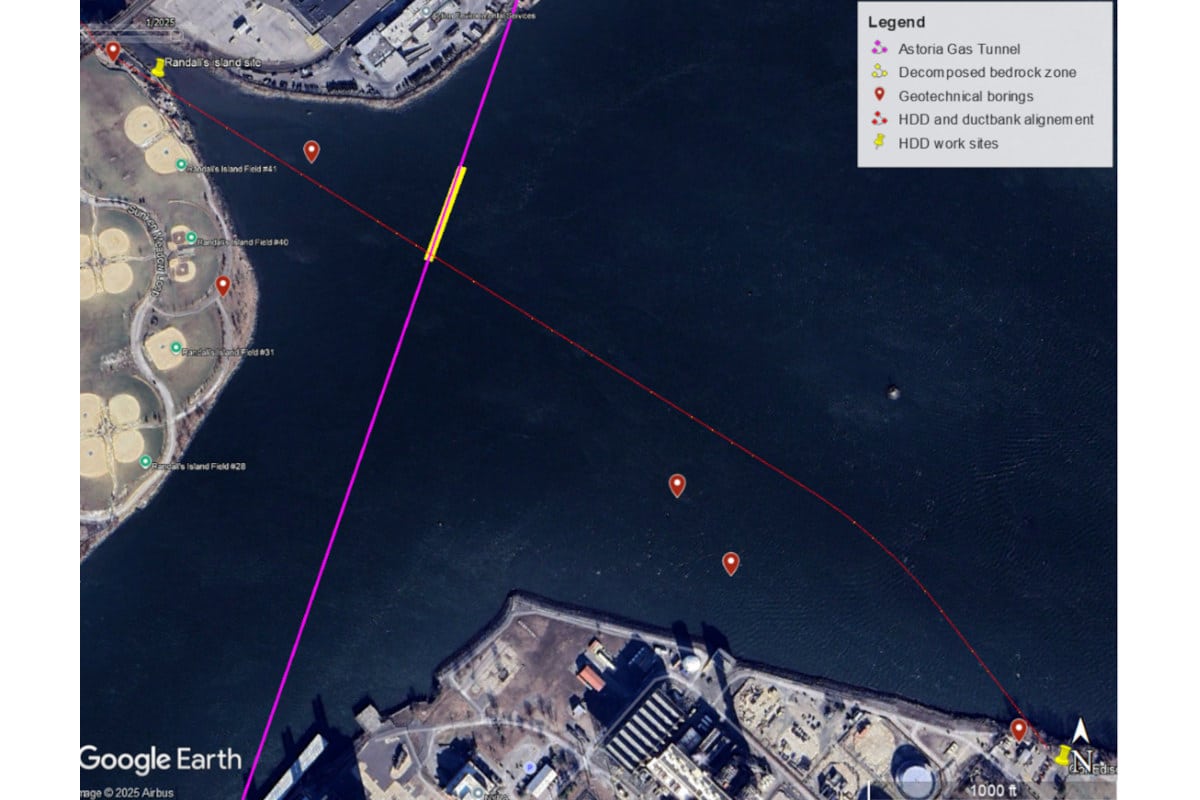

Located at the southern end of the CHPE project route the East River Randall’s Island to Astoria HDD consists of two bores approximately 5,100 ft in length. The bores extend from the northeastern edge of Randall’s Island Park, below the East River, to the northwest corner of Astoria, Queens. This section connects to the duct bank ending at the Astoria Converter Station on ConEdison property.

While the other terrestrial sections were installed as a single pass another option was put forth for this section.

The mile-long East River HDD crossing for the CHPE project was the longest HDD installation for HVdc transmission cables to date. Due to the known adverse bedrock conditions along the crossing, 20-in. diameter steel casing was required to protect the power cable and the fiber communication conduits.

Permalok interlocking jointed steel casing was selected over conventional butt-welded steel pipe for its advantage in eliminating field welding and the associated time and cost savings.

New Pipe for HDD

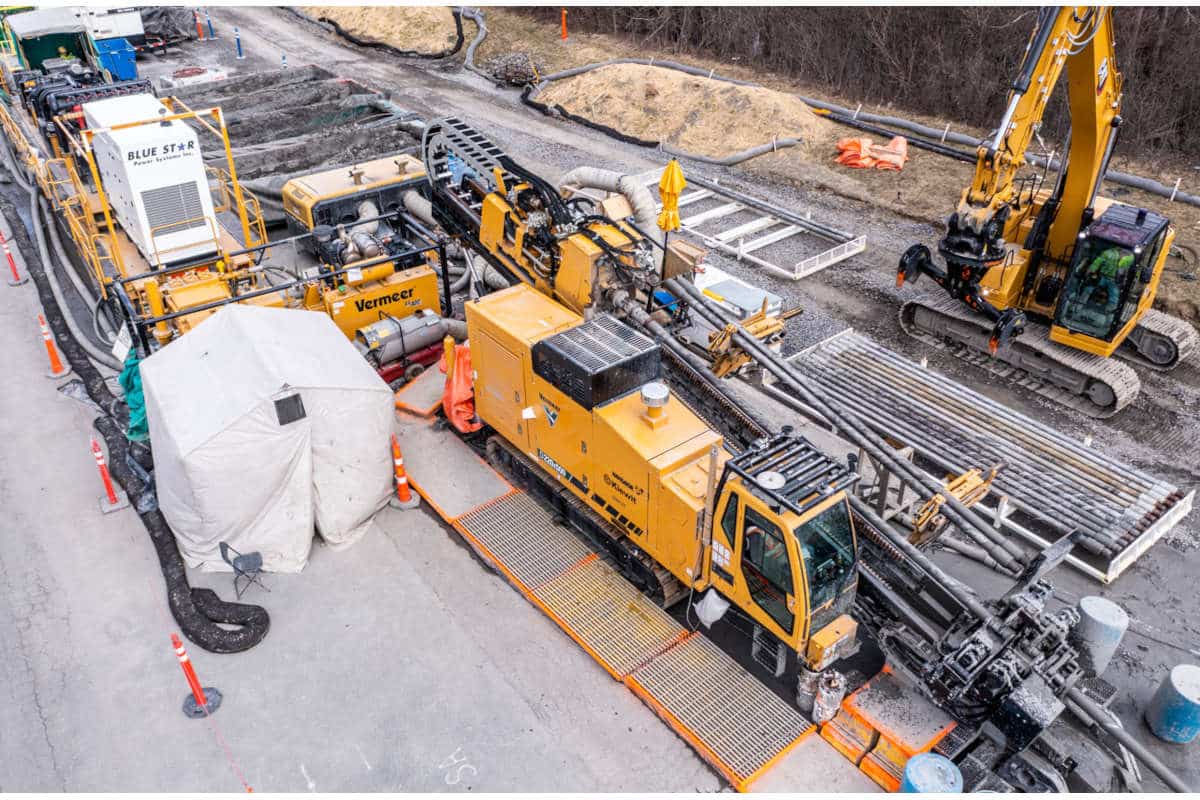

“In the big scheme of the trenchless industry Permalok is typically used for jacking operations. Here we were using it in a combined pull-plus-push operation,” says Smith. “Kiewit and Michels did extensive development testing with Permalok in the Michels yard in Brownsville, WI, prior to getting on site to ensure the system would work.”

A series of full-scale joint tension load capacity tests were designed and performed by Michels to determine the safe pull load for the support tension rig to aid the thrust installation.

“There were multiple years of planning with Kiewit not only on the timing, but making sure the equipment was there from the get-go. We needed to have spare parts for any challenges we might have encountered along the way and tooling for tooling changes on site before we started,” says Smith. “There wasn’t a lot of resupplies going on in the city. It was a one-time mobilization.”

Smith notes that to make this system work, Michels developed a special attachment for its HDD rig to make the sections of pipe go together in a seamless manner.

“This is certainly the longest installation of a non-welded mechanical connection steel casing. The entire crossing was put together in 170, 30-ft, segments,” Smiths says. For reference a typical HDD of this size and length would be done in one or two sections of pipe.

Despite challenging subsurface conditions, this record-length, first-of-its-kind installation of Permalok pipe specifically designed for HDDs was successfully completed with significant project schedule and cost savings.

Wrapping Up

To that end, Smith adds, “The project probably could have been built without the innovation. Would it have been built in the same timeframe? Probably not. You probably would have had more regulations on the environmental side, as well as land acquisition to have the necessary space for pipe layout and traditional assembly. You certainly would have disrupted the public a lot more than what was achieved here.”

When the dust settled, The Crossing Group completed approximately 134,637 ft of work on the project; Kiewit completed 92,690 ft; Haugland, 84,163 ft; Aaron Enterprises, 81,870 ft; and Michels, 27,214 ft.

“While The Crossing Group performed over half the HDDs, the real story is how a group of competitors came together under intense pressure to deliver something that had never been attempted at this scale,” says Perron. “This project changed how I see the industry. It redefined what’s possible when trenchless professionals set aside rivalry and focus on collective execution. And it proved, without question, that trenchless can scale—not just in length or depth, but in cooperation, in complexity, and in consequence.”

Mike Kezdi is managing editor of Trenchless Technology.

- How to Inspect and Assess Lateral Sewer Pipes

- Spotless Sewer Lines Play a Key Role in Lining Success

- How to Develop a Cost-Benefit Analysis for Pipeline Rehabilitation vs. Replacement

- How to Apply ASCE MOP 145 to Gravity Lining Projects

- How to Prepare and Trowel-Apply for a Manhole Rehab Project

Next Up

2026 Microtunneling Short Course | May 5-7, 2026 | Scottsdale, Arizona | Learn more