2013 Project of the Year – Rehab Winner

The piping had served a useful design life, however due to large numbers of breaks, water quality issues and restricted flows in some areas due to tubercles and pipe size, it was becoming an ever-increasing concern. In early 2009, money was budgeted for a large-scale pipe replacement program that would begin in 2010, with a goal of replacing the undersized and insufficient piping by dig-and-replace methodology. It was also during this time period that Consolidated started to investigate other methods of waterline rehabilitation as an alternative to the daunting open-cut program that was outlined.

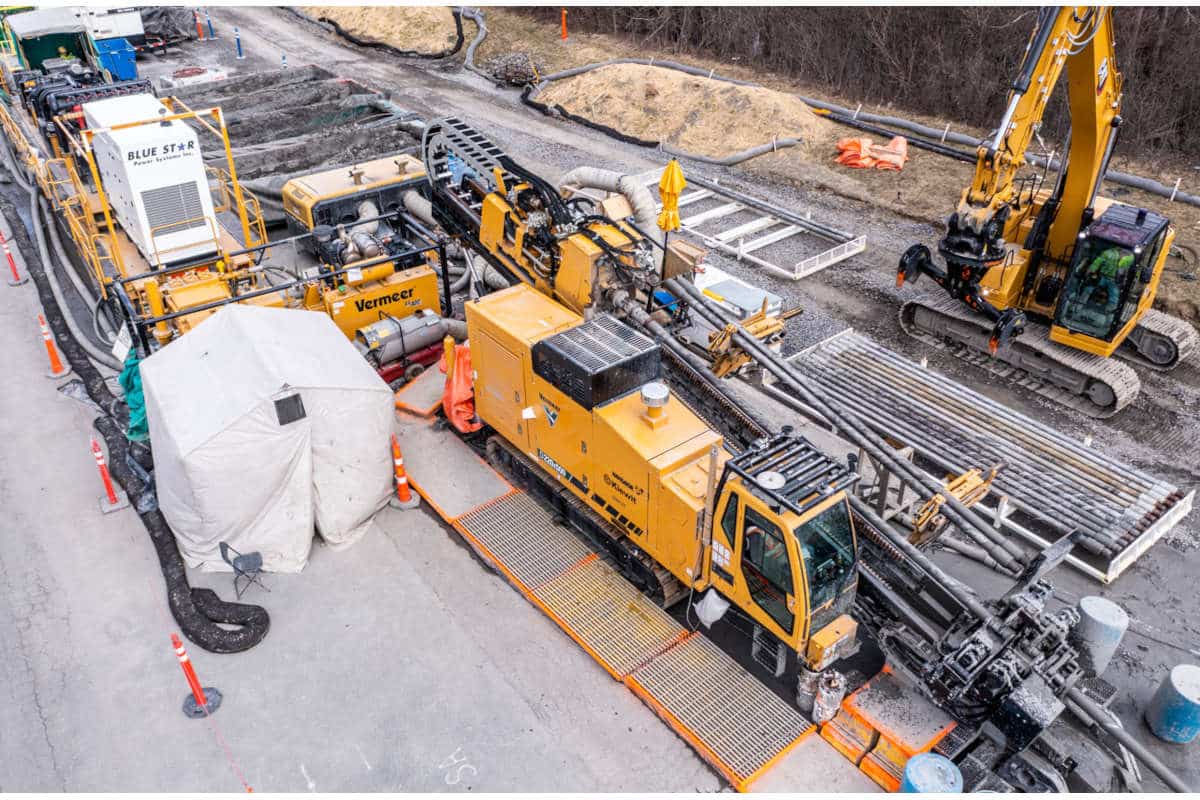

Consolidated began evaluating and testing a variety of equipment, pipe products and procedural methods for using pipe bursting technology. Consolidated decided to proceed with a pipe bursting program to replace 23,000 lf of water pipelines, beginning in April 2010 in a service area with antiquated and undersized lines.

As a result of the success of that phase, Consolidated has continued to use pipe bursting to replace more footage of water line each year, saving the company costs and reducing community disruption. For demonstrating the value of trenchless in maintaining and upgrading vital infrastructure — while simultaneously reducing costs and disruption — the Consolidated Mutual Water Company Pipe Bursting Program has been named the 2013 Trenchless Technology Project of the Year for Rehabilitation.

“Pipe bursting has been a real benefit to Consolidated,” said Mike Queen, president of the utility. “We are replacing more pipe at half the cost and we are using those dollars to offset the rising costs that we cannot control, such as fuel prices, insurance etc. This helps us keep our rates as low as possible for our stockholders without compromising the quality of water and service to our stockholders.”

Consolidated got started by first selecting the pipe technology, which was Underground Solution’s Fusible PVC pipe. Consolidated did this step in concert with getting the process approved with Denver Water. Next, Consolidated purchased a TT Technologies 800G static pull pipe bursting system to perform the bursting runs. When it decided to self-perform thermal butt-fusion of the Fusible PVC, Consolidated purchased McElroy fusion equipment to install DR 18 Fusible C-900 PVC pipe. Consolidated enlisted the technical assistance from the manufacturers when it initiated the pipe bursting program and have been fully self-performing the installations with efficiency ever since. Typical pipe bursting runs are in the range of 500 to 800 lf.

From this start in 2010, Consolidated has burst approximately 123,000 lf of pipe — about 23 miles total — progressing from 33,000 lf in 2011 to 43,000 lf in 2012. Consolidated replaces potable water distribution pipelines by first setting up temporary water service in the area of construction. The utility then switches service over to the temporary main, prepares the existing line, burst and installs a new pipeline, flush and test the new line, transfer service back to the new pipeline and make the appropriate surface restoration as needed.

Underground Solutions CEO and president Andy Seidel says that Consolidated is an example for other utilities and municipalities. “In a time of constrained utility budgets and tight capital spending, Consolidated Mutual Water Co. has shown that it can rehabilitate more infrastructure and spend less money by adopting trenchless technology. Their experience is a call to action for utilities across the country. Through the use of trenchless technology, utilities can actually do more with less. Consolidated illustrates for all of us how utilities can gain ground on their infrastructure problems instead of kicking the can further down the road.”

On the surface what Consolidated does each year with the potable water pipe rehabilitation program is what we expect from our public utilities: to invest in the existing system. Upon closer inspection, what Consolidated has achieved with a very finite set of resources is remarkable. Key elements of the program include:

Self-Performing Utility: Consolidated is a 100 percent, self-performing utility whose productivity, cost performance and installation quality meet, and in some cases exceed, the best specialty contractors in private industry. It is extremely rare to see a utility self-perform trenchless work with performance benchmarks that reach these levels. Consolidated has quietly become one of the best pipe bursting entities in North America.

- Continuous Improvement: Consolidated began the pipe bursting program with strong performance metrics in its first year, and has raised the performance bar each subsequent year with the same crew and equipment. One crew is installing more than 40,000 ft in a few short months (due to a limited construction season). In the first year of the program, Consolidated installed pipe via pipe bursting at twice its historical installation rate for open-cut.

- Cutting Edge Achievement: Consolidated has completed multiple, continuous pipe burst runs exceeding 1,800 ft in length. Few contractors in North America have documented installation lengths in this range. Consolidated is helping to define cutting edge in the trenchless industry.

- Industry Leading Advocacy: Consolidated has hosted more than 1,000 visitors to its jobsites over the last four years. Utilities, consulting engineers and contractors have come from all over North America to learn from Consolidated’s pipe bursting program. During the recent AWWA ACE conference in Denver, Consolidated hosted officials from Indianapolis Water and Louisville Water. Queen is a frequent presence at national technical conferences presenting Consolidated’s success story. Queen has given technical papers at No-Dig and AWWA, as well as other national, state and regional conferences. Consolidated has hosted a Field Day with the Rocky Mountain Chapter of NASTT. Queen and his crews welcome all visitors and generously share their means, methods, accounting and decision-making — a rarity for a utility.

- Documented Cost-savings: One of the challenges in growing the trenchless market is generating accurate data that confirms the economic and social benefits of trenchless technology. Consolidated has carefully documented its pipe bursting costs since inception of the program, making detailed comparisons vs. its open-cut installation costs. In the first year of the program, Consolidated halved its per linear foot cost of installed pipe compared with dig-and-replace costs, and it has improved upon that benchmark each subsequent year.

- Beneficial Impact to the Community: Aside from an improved distribution system with fewer leaks, breaks, water quality concerns and maintenance issues, the socioeconomic benefits to the community have been significant. Work on a typical block takes a week or less and does not limit the access to any homeowner or business. Residents have delivered baked goods to the crew to thank them for improving the water service while minimizing impact to the community.

- Positive Contribution to the Industry: Consolidated has provided support to surrounding utilities to demonstrate how alternative rehabilitation methods such as pipe bursting can solve their water system deficiencies. Queen and his team have met with many local utilities that have since begun pilot or full-scale pipe bursting programs, including Denver Water, Aurora Water, Cherry Creek Water, Wheat Ridge, North Washington Water & Sanitation District and Loveland Water District. Consolidated has gone the extra mile for its rate-payers and has achieved in real dollars what many organizations only pay lip service to, which is “Doing more with Less.”

For Consolidated, these are not merely words but constitute an operating philosophy, an organizational mission and a daily mantra. Consolidated’s program embodies everything that trenchless techniques promise: cost-savings, efficiency, positive social impact, value for constituents and delivery of improved infrastructure with less hassle. Consolidated’s rehabilitation program is proof that trenchless technologies deliver value and are viable for every utility regardless of size.

Jim Rush is editor of Trenchless Technology.

Project Owner/Engineer/Contractor: Consolidated Mutual Water Co.

Manufacturers/Suppliers: TT Technologies, Underground Solutions, McElroy

Self-Performing Utility: Consolidated is a 100 percent, self-performing utility whose productivity, cost performance and installation quality meet, and in some cases exceed, the best specialty contractors in private industry. It is extremely rare to see a utility self-perform trenchless work with performance benchmarks that reach these levels. Consolidated has quietly become one of the best pipe bursting entities in North America.

Self-Performing Utility: Consolidated is a 100 percent, self-performing utility whose productivity, cost performance and installation quality meet, and in some cases exceed, the best specialty contractors in private industry. It is extremely rare to see a utility self-perform trenchless work with performance benchmarks that reach these levels. Consolidated has quietly become one of the best pipe bursting entities in North America.