The Key Steps in Mainline and Lateral Grouting

Injection grouting using acrylamide grout is known as one of the original trenchless technologies and has a long and successful, track record, spanning decades.

Injection grouts are used to eliminate infiltration in structurally sound mainlines, laterals, lateral connections and manholes among other underground structures. The infiltration carries soil fines into the system, eroding supporting soils and creating voids outside the pipe or manhole which can lead to sinkholes. The soil fines settle in the mainlines, reducing the pipe’s designed sewerage capacity, which often leads to an increase in SSOs, requiring the need for cleaning more often.

As infiltration continues, the collection system will eventually become structurally incapable and what could have been a simple repair becomes a costly rehabilitation project, a complete replacement or a danger to the surrounding community.

Injection grouts do not stop sewer leaks by simply filling joints and cracks. Instead, grout is forced under pressure through joints and cracks and into the surrounding soil where it gels with the soil to form a waterproof mass which cannot be pushed back into the sewer system. Grouting provides additional support to the system while preventing further soil erosion.

RELATED: NASSCO Report – Infiltration Control Grouting Committee

The most economical way to stop infiltration in structurally sound pipes such as mainlines and laterals is with injection grout. This how-to will walk you through the steps to mainline and lateral grouting your collection system.

Mainline Grouting

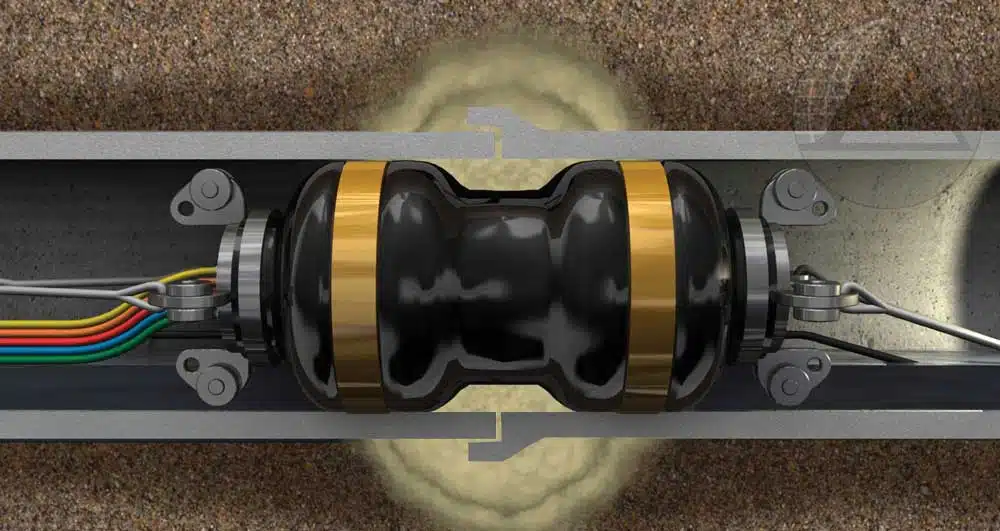

Mainline grouting is executed using multiple technologies: a grout truck (or customized rig), inflatable mainline packer (for use in 6- to 120-in. pipe) and a low viscosity, two component injection grout such as acrylamide.

From the grout truck, an operator controls all aspects of the project. Closed-circuit television (CCTV) is used inside the pipe to locate the joint, crack, or defect to be tested and/or injected, and to strategically position the packer in place, and inflate the packer’s end bladders.

It is important to air test all the joints as joints that were not visibly leaking during video inspection may leak in the future after sealing surrounding joints. Joints that fail the air pressure test can immediately be injected and sealed with grout – with or without visible leaks.

Grout is forced under pressure through the joint or defect into the surrounding soil forming a waterproof mass that cannot be permeated by water. The operator will pump the grout through the defect until refusal – or until grout has filled the void area outside pipe.

A general rule of thumb for the volume estimate of grout needed to seal a mainline joint is 0.5 gallons of grout per inch diameter of pipe. For example, if the mainline pipe is 8 in., a fair estimate per joint is 4 gallons. After the joint or defect is properly sealed, a post-air pressure test is administered. If the joint or defect does not leak air, it will not leak water.

Once documented, the packer’s bladders are deflated, and it gets moved to the next joint or defect in the pipe to repeat this process. Mainline grouting can also be used as a complimentary technology to pipe lining. By eliminating infiltration before lining pipes, maximum performance is achieved by creating an infiltration-free environment for the lining process.

Lateral Grouting

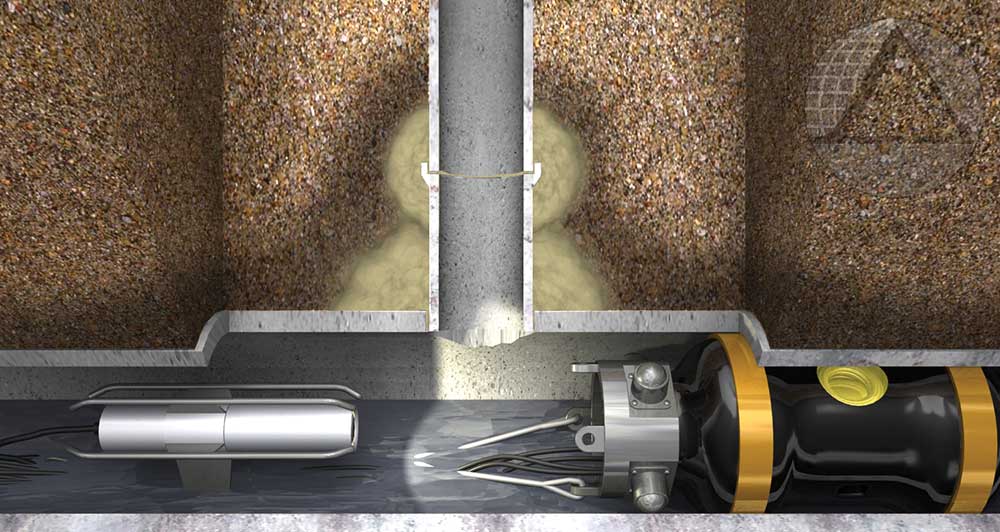

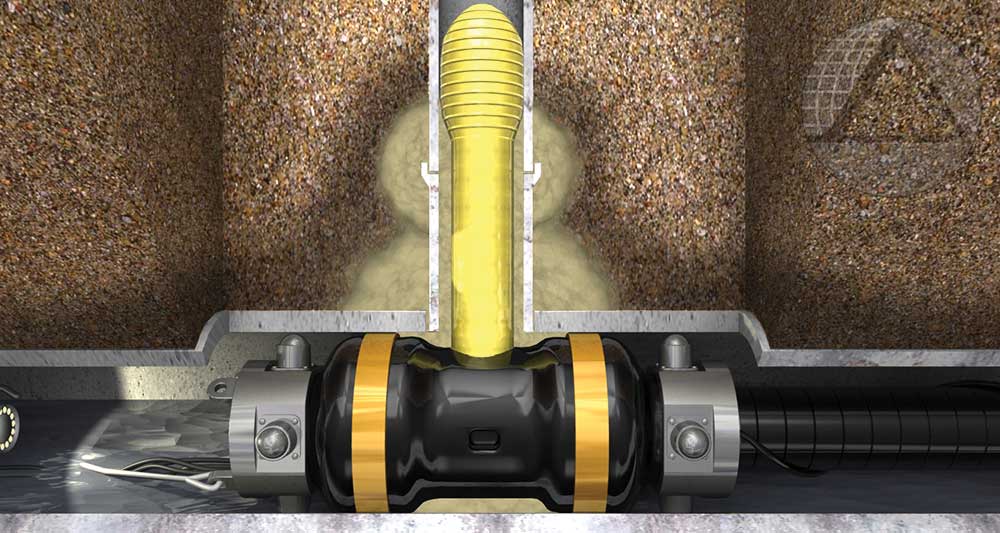

Lateral grouting is completed much like mainline grouting, except the packer has an inflatable plug that extends up the lateral from the mainline.

Once the packer is positioned in place, the lateral plug is fully inverted up the lateral, and the mainline bladders are inflated. The top, ribbed portion of the lateral plug expands against the lateral pipe wall, while the lower portion expands enough to create a thin annulus for the grout to travel between packer and pipe.

Grout is forced under pressure through the defects into the surrounding soil forming a waterproof mass that cannot be permeated by water. A general rule of thumb for the volume estimate of grout needed for sealing a lateral is 0.33 gallons of grout per inch diameter pipe plus an additional gallon per foot of lateral. For example, if the lateral pipe is 6 in. and you are sealing 3 ft up the lateral, a fair estimate per lateral is approximately 5 gallons.

After the lateral is properly sealed, a post-air pressure test is administered. If no leaks are detected, the seal is documented, mainline bladders are deflated, the lateral plug is reinverted into the packer assembly, and the packer is moved to the next lateral in need of rehabilitation.

RELATED: Taking Ownership of I/I Issues with Injection Grouting

Depending on application and municipal requirement, lateral grouting can be performed as far as 35 ft from the mainline. Lateral grouting can also be a complimentary technology to lining pipes.

After lining, grout is the optimum technology to seal the annulus between host pipe and liner at the lateral reinstatement – a primary source of infiltration.

Injection Grout Is Here to Last

At times, grouting has been misconstrued as a temporary fix that will dehydrate and only last a few years. These misconceptions are false. Third party studies over longevity and hydration of grout have shown:

- Properly injected acrylamide grout at 20 percent concentration has a 362-year half-life in the soil determined by the United States DOE. Most acrylamide grout in municipal applications is injected at 10 percent or 12 percent concentrations making the approximate life expectancy more than 50 years.

- At typical depths that sewer systems are located underground, there is enough relative humidity (RH) to keep the acrylamide grout hydrated thus never dehydrating or shrinking (Doug Cobos, 2018).

Everyday communities battle infiltration in their collection systems. At first, infiltration may not seem troublesome. However, when infiltration is allowed to exist over time, systems become compromised, and the safety of the community may be in jeopardy. A proactive rehabilitation approach versus a reactive repair or replacement approach should be top of mind. For decades, injection grouts have been the most economical product to stop infiltration in structurally sound collection systems.