The Benefits of SAPL Lining for Large Diameter Pipe

There are various methods for trenchless restoration of large diameter pipe that convey storm water, sanitary sewage, both as gravity and pressure flows. Additionally, these methods are used for pressurized drinking water transportation.

This article focuses on large diameter pipe in storm and sanitary gravity systems where exterior loading is the critical design consideration. The reader should refer to ASCE Manual of Practice 120 “Trenchless Renewal of Culverts and Storm Sewers” for a more thorough discussion. It covers all methods of rehabilitation of 1 m and larger storm pipe. MOP-120 is currently is in process of receiving updates by the Pipeline Infrastructure Committee (PINS). Additionally, the SAPL lining method has its own standard, ASTM F-3706-24.

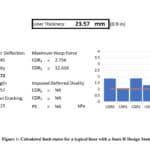

There are excellent reasons to select Spray Applied Pipe Lining (SAPL) for large diameter pipe. Aside from the obvious benefits of trenchless, quick and comparatively less expensive, the primary benefit is engineered thickness design. It withstands the long-term exterior pressures placed on a deeply buried pipe.

This renewal system corrects minor problems before they become disasters and structural failures. Its field-verified design methodology addresses soil loads, dynamic traffic loads and ground water loads. This enables the calculation of the properly applied thickness for the material properties of the SAPL liner for a full structural replacement. Installers uniformly apply fine aggregate concrete to the prepared interior pipe surface. It’s compacted in one or more layers and is most common.

However, not all liner materials have the same properties. Increasing thickness, to a degree, may compensate for other material properties shortcomings.

- How to Inspect and Assess Lateral Sewer Pipes

- Spotless Sewer Lines Play a Key Role in Lining Success

- How to Develop a Cost-Benefit Analysis for Pipeline Rehabilitation vs. Replacement

- How to Apply ASCE MOP 145 to Gravity Lining Projects

- How to Prepare and Trowel-Apply for a Manhole Rehab Project

Next Up

2026 Microtunneling Short Course | May 5-7, 2026 | Scottsdale, Arizona | Learn more