Steel Pipeline Inspections Keep the Water Flowing in Sunny Saskatoon

When it comes to pipelines, being proactive is about understanding risk and making informed decisions for safe, reliable, and affordable service. The City of Saskatoon is undertaking a proactive condition assessment program to maintain its aging primary water mains. Now, new assessment technologies for metallic pipelines have enabled the city to expand its program.

The South Saskatchewan River flows through the center of Saskatoon, supplying the city with drinking water and earning it the title City of Bridges. The City of Saskatoon treats and delivers water to about 318,000 residents in the Canadian province of Saskatchewan.

The City operates more than 1,190 km (740 miles) of water pipelines. This includes 119 km (74 miles) of large-diameter primary water mains with a replacement value of CA$282 million. In 2014, the City identified and prioritized its high-risk primary water mains, creating a ranking system used to prioritize pipelines for condition assessment on an annual basis.

The City’s long-term asset management plan has helped reduce main breaks across the distribution system. In 2020, there were 198 main breaks compared to the 10-year average of 239. Targeted pipeline maintenance and renewal is improving system reliability and customer satisfaction.

Innovation in Metallic Pipe Assessment

Primary water mains are critical for Saskatoon. The City needed inspection methods that could locate and quantify defects on a pipe-by-pipe basis without removing the mains from service. Recent developments in metallic water pipeline inspection technology enabled the City to manage risk more effectively across their transmission network.

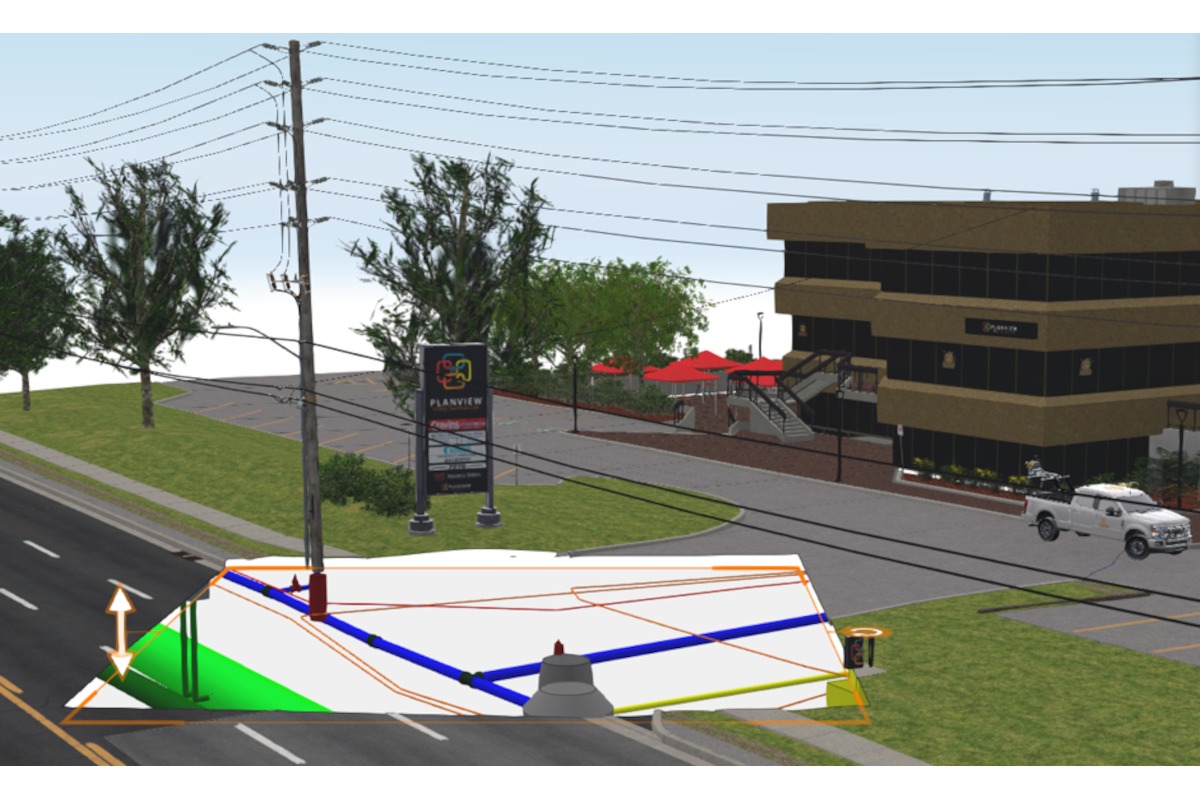

In 2020, the City of Saskatoon assessed 7.8 km of large-diameter steel water mains. Using multiple technologies, the City collected data on wall thickness and out-of-roundness, pipe coating condition, pressure transients and leaks.

The inspections identified higher risk pipe sections at a highway crossing, but overall, both pipelines inspected are in serviceable condition. Structural analyses also resulted in next-step recommendations, data-driven reinspection intervals and an overall estimated pipeline life expectancy.

Data Collection on Steel Pipelines

The 1st Avenue Primary Water Main is 600 mm (24 in.) in diameter and runs through downtown Saskatoon. The 1,067-mm (42-in.) Acadia Fill Main is a non-redundant pipeline that runs from the Saskatoon Water Treatment Plant, under the South Saskatchewan River, and through well-established neighborhoods in the southeastern part of the city. Due to the location and size of these pipelines, a failure could result in significant community disruption.

The City of Saskatoon partnered with Pure Technologies, a Xylem brand to assess 1.43 km (0.9 miles) of the 1st Avenue Primary Water Main and 6.35 km (4 miles) of the Acadia Fill Main.

First, Pure Technologies monitored pressure continuously on both pipelines for more than 50 days. The pressure transients observed on both pipelines are indicative of pump start up and shutdown. A potential for negative pressures along the Acadia Fill Main also warrants further investigation.

Transient pressure monitoring helps utilities understand internal loading on the system during everyday operations. By identifying the operational conditions that cause pressure transients, utilities can take steps to mitigate them.

Next, the team deployed the free-swimming SmartBall platform to inspect the pipelines for leaks and gas pockets. Pitting corrosion and cracking can cause steel pipes to leak. Identifying and repairing leaks early can prevent larger problems. Leak detection also reduces water loss and saves energy associated with drinking water treatment and pumping.

The SmartBall platform is an inline tool that rolls along the bottom of the pipeline listening for the signature acoustic signal of a leak. The tool identified one leak on the 1st Avenue Primary Water Main that was likely related to a hydrant or its point of connection.

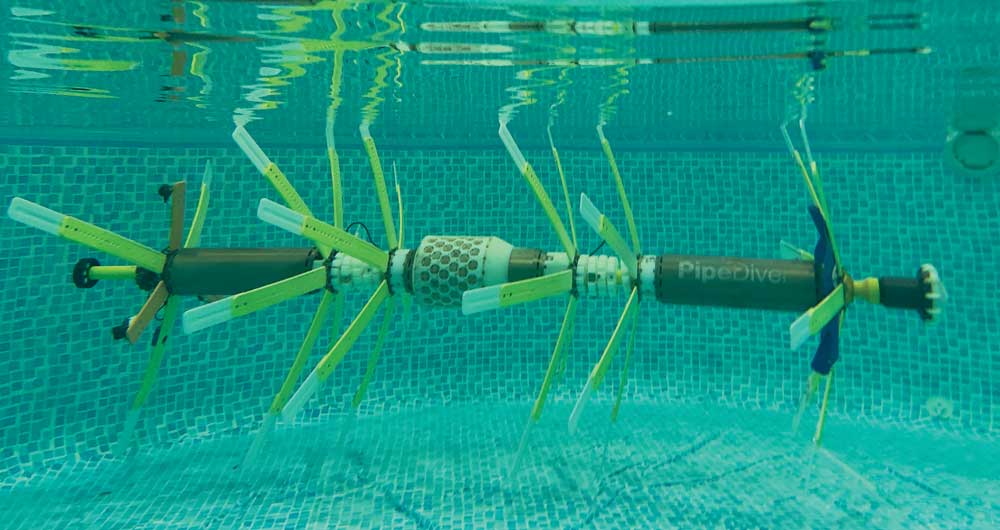

The team then deployed PipeDiver Ultra to measure the wall thickness of the steel pipes and identify and locate corrosion. Ultrasonic technology enables high-resolution internal and external wall loss measurements. Wall loss decreases a steel pipe’s overall strength, and corrosion is the primary cause of failure in metallic pipes.

On each pipeline, the tool identified five pipes with external wall loss. This represents less than 2 percent of the total pipes inspected across both pipelines. On the Acadia Fill Main, Pipe 10573 had multiple localized areas of corrosion. The most severe defect was 2,500 sq cm (385 in2) with a maximum wall loss of 40 percent.

PipeDiver Ultra also found that both pipelines contained a significant number of pipes with out-of-roundness greater than five percent, making them more susceptible to coating and lining damage. The tool’s onboard cameras identified several sections with lining delamination.

While steel pipes are flexible, they can deform, crack, or even buckle under excessive loading. Pipes with wall loss are more vulnerable to the threats caused by out-of-roundness. In turn, lining and coating damage caused by out-of-roundness make the pipeline more susceptible to corrosion. Measuring these datasets together helps utilities better understand overall risk to the pipeline.

From Data to Decisions

Pure Technologies performed three structural analyses on the pipelines using the inspection and monitoring results. Both the 1st Avenue Primary Water Main and the Acadia Fill Main had some defects, but analyses confirmed that no pipes required immediate repair or replacement. There were two pipes of concern on the Acadia Fill Main. Located under a major highway on a nonredundant pipeline, the consequence of a failure is high.

Finite element analysis determines the severity of corrosion and out-of-roundness that would exceed the yield limit of a steel pipe. Acadia Fill Main Pipe 10576 had the highest out-of-roundness of any inspected. Although the pipe can continue operating at normal working pressures, the analysis showed it would reach its yield limit at 230 psi – the maximum operating pressure plus surge pressure.

The neighboring Pipe 10573 was also of some concern. Based on a remaining useful life analysis, it has a 50 percent chance of failing in the next 16 years.

Remaining useful life analysis helps determine reinspection intervals and estimated pipeline life expectancy. The five pipes with defects on the 1st Avenue Primary Water Main have an average remaining useful life of more than 87 years. On the Acadia Fill Main, four of the pipes with defects have an average remaining useful life greater than 46 years.

The City of Saskatoon now has the data to make informed decisions and mitigate risk on two critical steel water mains. Through its proactive asset management program, the city is ensuring water services meet the needs and expectations of Saskatoon citizens today and into the future.

In 2020, the City of Saskatoon assessed 7.8 km of large-diameter steel water mains. Using multiple technologies, the City collected data on wall thickness and out-of-roundness, pipe coating condition, pressure transients and leaks. The inspections identified higher risk pipe sections at a highway crossing, but overall, both pipelines inspected are in serviceable condition. Structural analyses also resulted in next-step recommendations, data-driven reinspection intervals and an overall estimated pipeline life expectancy.

Justin Hebner is business development manager at Xylem and Josh Greenberg, condition assessment engineer at Xylem. Stephen Wood is preservation manager with Water and Sewer for the City Saskatoon.