Pipe Cleaning Products

KEG Technologies

KEG Technologies

KEG Technologies Inc. introduced a solution to the need for cleaning large diameter infrastructures. As individual states increase the regulations of groundwater conveyance, control, and treatment, the need to convey groundwater also increases. Groundwater conveyance is typically uses large pipes that are hard and/or maintenance intensive to keep clean. The use of either a “Twin 6” or “Twin 8” set of floor cleaners, both sanitary and storm water maintenance organizations can now clean these infrastructures using the current cleaning equipment they already own. The result is a less maintenance intensive method for maintaining the infrastructures. Box culverts, arch pipe, and 48-plus in. pipes have met their match.

NozzTeq

NozzTeq

NozzTeq introduces a new sewer or storm cleaning nozzle, the BL Swiper, patent pending, for pipe sizes 8 to 18 in. The construction of the BL Swiper is made to optimize the cleaning effect by using both the water flow from the jets and air flow in the pipe. The water flow, through the pressure in the jets, creates a jet stream and the jet streams create thrust through a number of air channels. The number of air channels is equal to the number of water jets. The channels are placed in the center of the nozzle, meaning that the total force generated by the nozzle, both air and water force, are used to clean the pipe cost-effective. Tests performed with the BL Swiper have determined that the flow rate can almost be cut in half, compared with normal flow needs.

StoneAge

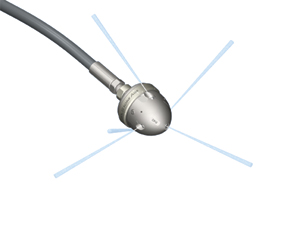

StoneAge recently released its Bigger Badger, to its family of pipe cleaning tools. This new Bigger Badger is designed to clean 6-in. pipes with 90-degree bends and is offered for 15,000 psi with a ½-in. npt inlet or for 20,000 psi with a 9/16 Medium Pressure inlet. The flow capacity is from 14 to 55 gpm. The Bigger Badger is designed similar to StoneAge’s existing model and uses a stack up of discs to help control the speed of rotation. The range of speed control is from 50 to 300 rpm. Tough applications will need the slow rpm while easier jobs can be finished quicker with faster rpm. The most impressive feature of the Bigger Badger is that StoneAge has added a simple but effective speed control called the Adjustment Sleeve. By using an open end wrench, the operator can easily tighten or loosen the Adjustment Sleeve. Now operators have the ability to maximize productivity from job to job by simply changing the Adjustment Sleeve. There is no disassembly or fluid change required. The Bigger Badger tool also offers a tremendous amount of versatility by simply changing the nozzle sizes.

![]()