NASSCO Report – CIPP Lining of Elliptical HDPE in Omaha

The 6th and Leavenworth Grit Facility effluent sewer is a 40-in. diameter HDPE pipe constructed in 1977 that traverses 820 ft from the grit facility to a diversion structure near the banks of the Missouri River in Omaha, Nebraska.

The Grit Facility was constructed in 1977 and abandoned after construction of the Leavenworth Lift Station and Bypass Structure in 2014. Since the Grit Facility’s abandonment, City staff have observed that without an effective means to remove grit, debris is accumulating behind the diversion structure weir and eventually overtopping and accumulating in the downstream bypass structure and Leavenworth Lift Station wet well.

To address these concerns, the Grit Facility was rehabilitated, improved, and returned to service in 2024. Improvements were also needed to the diversion structure by replacing the existing slide gate to prevent debris accumulation. In addition, structural repairs were needed for the 40-in. diameter effluent sewer to complete a comprehensive rehabilitation of the infrastructure.

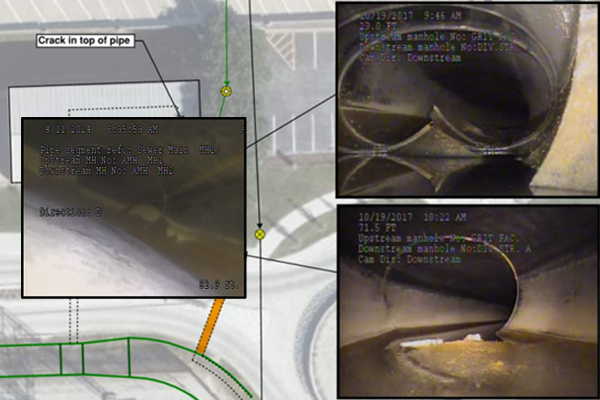

Record drawings showed that the effluent sewer pipe contained multiple bends, including a sweeping 90-degree bend, travels below many utilities, and runs adjacent to a large electrical substation. Inspections of the effluent sewer were performed to evaluate the structural integrity of the pipe and identify necessary improvements. In addition, the City of Omaha Public Works also obtained Lidar scanning to properly assess the actual pipe shape since initial CCTV inspection showed significant ovality in some locations. The detailed investigations indicated that the pipe is actually 36 in. in diameter, rather than 40 in., as shown in the record drawings.

The inspections also identified multiple defects including broken, buckling pipe in the invert, leaking joints, and an ovality in some locations as much as 20 percent. Due to the dramatic ovality, the pipe dimensions were actually 28.8 in. tall by 43.2 in. wide in the portion of the pipe upstream of the sweeping 90-degree bend.

A variety of alternatives were evaluated to develop a cost-effective solution. Although the pipe makes multiple 90-degree bends and has limited upstream and downstream access due to the grit facility and diversion structure, respectively, a trenchless solution was preferred. In addition, because the pipe had greater than 20 percent ovality in some locations, it was necessary to design the liner based on WRc state III design guidelines.

It was originally thought that the buckling pipe in the invert could be cut out manually and then lined through. However, excavation adjacent to this section of the pipe that was required to install a new 5-ft diameter manhole, as well as other work related to the grit facility rehabilitation, prompted the contractor to simply cut out this defective portion of pipe and replace it.

Following this point repair the pipe was CIPP lined going upstream from the diversion structure, through the sweeping 90-degree bend and the 22.5-degree bend, through the new manhole and into the grit facility. The diversion structure was accessed via an expanded access hatch over the existing above ground vault and weir structure.

Manned entry was required from this access hatch to locate the intersection of the effluent sewer pipe, which was encased in concrete. The concrete encasement and flanges needed to be removed to expose the effluent pipe where it intersects with the north barrel connection so that insertion could be performed from this location.