Lateral Lining in Florida

April 2, 2014

Today’s municipal infrastructure projects are often awarded to the lowest bidder. Too often that is also coupled with a utility’s use of bid specifications driving work to a lowest common denominator approach that saves money in the short-run, but leads to a low quality solution and increased costs for the long term.

Today’s municipal infrastructure projects are often awarded to the lowest bidder. Too often that is also coupled with a utility’s use of bid specifications driving work to a lowest common denominator approach that saves money in the short-run, but leads to a low quality solution and increased costs for the long term. Here is how one Florida community reduced inflow-and-infiltration (I/I) by 232 million gals and stands to save $368,000 per year, with an investment of $1 million.

What makes this project different from other lining projects?

The Coral Springs Improvement District, located in Broward County, Fla., is contained within the City of Coral Springs. The District manages its own collection and water systems and is home to around 45,000 residents.Lift Station Basin No. 1 was placed in service in 1974; the collection basin serves more than 400 single family homes. There are approximately 20,600 ft of 8-in. VCP mainline pipe and 6,000 ft of 6-in. VCP lateral pipes. In 1999, the District lined 17,000 ft of mains to reduce pump run times which produced positive results, but not the long-term results they needed. The District had continued to experience unacceptably high levels of I/I. The laterals were suspected as the major cause of the problem, so the District took an aggressive approach to investigating the root cause of the problem and finding a long-term solution.

Twenty-year-veteran, director Dan Daly of the Coral Springs Improvement District, was the driving force behind the project. Day-to-day management of construction was overseen by foreman Curt Dwiggins and field supervisor Steve Seigfried.

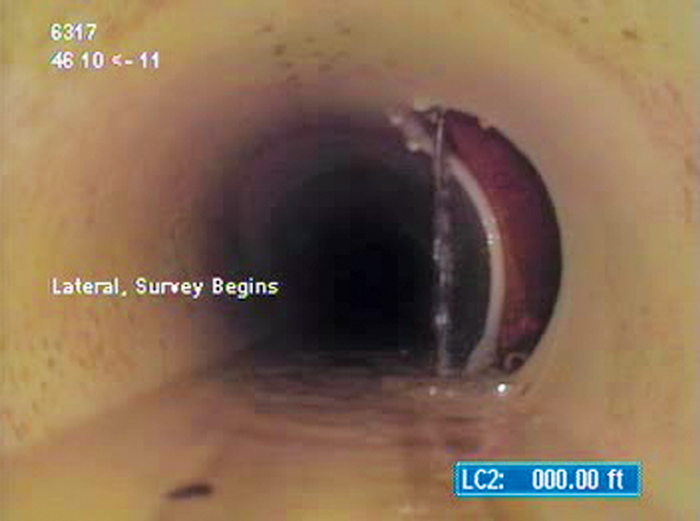

Twenty-year-veteran, director Dan Daly of the Coral Springs Improvement District, was the driving force behind the project. Day-to-day management of construction was overseen by foreman Curt Dwiggins and field supervisor Steve Seigfried. The first phase of the project consisted of inspecting all laterals in the entire basin area, and mainline pipe that was not lined in previous years. The laterals were inspected by launching a camera up the lateral from the main to the private property line. Inspecting the laterals was challenging because the infiltrating groundwater kept the system surcharged. LMK Pipe Renewal of Fort Lauderdale provided organized spreadsheets and PACP video inspection reports identifying the condition of the pipe and what repairs would be required to seal the system.

It was determined there were three major sources of infiltration occurring:

1. Groundwater was tracking behind the mainline liners and entering the system where the mainline liner was cut open to reinstate the service connections. Additionally, the terminating ends of the old mainline liners were leaking allowing ground water to enter the system.

2. The lateral survey revealed leaking lateral pipe defects such as cracks, calcium deposits, offsets, holes, roots and staining.

3. There were also defective mainline segments that were not lined during the 1999 project.

The District was quite clear about new repairs to the system: The goal was to “seal the system, not just line it.” The hidden value rested in sealing the mainline water tracking issues and renewing the laterals with a positive seal to the mainline liners. All materials installed on this project were required to comply with industry recognized ASTM standards. The lateral pipes were renewed and sealed in accordance with ASTM F2561-11, which was comprised of a one-piece full-hoop main and lateral CIPP outfitted with compression gaskets. The mains that were renewed with CIPP were installed in accordance with ASTM F1216 and the terminating ends were also sealed by use of Insignia Seals, which are tubular molded swelling compression gaskets.

The District was quite clear about new repairs to the system: The goal was to “seal the system, not just line it.” The hidden value rested in sealing the mainline water tracking issues and renewing the laterals with a positive seal to the mainline liners. All materials installed on this project were required to comply with industry recognized ASTM standards. The lateral pipes were renewed and sealed in accordance with ASTM F2561-11, which was comprised of a one-piece full-hoop main and lateral CIPP outfitted with compression gaskets. The mains that were renewed with CIPP were installed in accordance with ASTM F1216 and the terminating ends were also sealed by use of Insignia Seals, which are tubular molded swelling compression gaskets.  The District’s concerns were solved by the incorporation of compression gaskets at the service connections and the terminating ends of the CIPP lateral lining. These gaskets provide the same type of seal that is used on PVC pipe, DIP, concrete pipe, etc., but these gaskets are designed specifically for use with CIPP and folded plastic liners. When the gaskets are positioned between the pipe-liner and the host pipe, they create a compression gasket as they swell in the presence of moisture or water. These gasket seals make CIPP similar to that of new direct bury pipe. An added benefit that the District liked is the gaskets; they’re visible through the liner allowing inspectors to be certain that a seal is properly placed and verifiable.

The District’s concerns were solved by the incorporation of compression gaskets at the service connections and the terminating ends of the CIPP lateral lining. These gaskets provide the same type of seal that is used on PVC pipe, DIP, concrete pipe, etc., but these gaskets are designed specifically for use with CIPP and folded plastic liners. When the gaskets are positioned between the pipe-liner and the host pipe, they create a compression gasket as they swell in the presence of moisture or water. These gasket seals make CIPP similar to that of new direct bury pipe. An added benefit that the District liked is the gaskets; they’re visible through the liner allowing inspectors to be certain that a seal is properly placed and verifiable.There is a common misunderstanding about CIPP pipe lining. Assumptions that the resin sticks or bonds to the host pipe are not valid; little or no bonding occurs and the explanation is practical from an engineering design point of view. The host pipe actually acts like a mold, yet shrinkage commonly occurs through polymerization of the resin, and thermal expansion/contraction occurs along with earth movement. Likewise, FOG (fats, oil and grease) prevents bonding. These conditions create an annular space where the constant groundwater pressure migrates between the pipe and the liner only to leak back into the system at lateral reinstatements and into the manholes. The Insignia Seals situated in the annular space, expand and form a compression seal between the host pipe and the new liner.

“For the past five years, CSID has been upgrading and updating much of our infrastructure. We had many projects that went smoothly and a few projects that seemed to have a life of their own. Fortunately the LMK relining and system sealing was the smoothest project to date. Between our CSID personnel and LMK’s project manager and crew, we were happy to be able to report our progress to the Board of Supervisors each month. There were not any change orders needed for this project and LMK finished on time,” said Daly. “Since we operate our own wastewater treatment plants here on our CSID campus, we are able to appreciate the reduction of inflow on a daily basis when our area receives a large amount of rain. No longer are we processing rain water inflow that used to manifest itself in Lift Station 1 due to leaking laterals and tree root laden sewer pipes. It was very important to CSID to have documentation and video of the entire project, start to finish. We are currently evaluating another Lift Station basin and anticipate beginning the camera documentation soon, and you can bet that we will opt for LMK.”

“For the past five years, CSID has been upgrading and updating much of our infrastructure. We had many projects that went smoothly and a few projects that seemed to have a life of their own. Fortunately the LMK relining and system sealing was the smoothest project to date. Between our CSID personnel and LMK’s project manager and crew, we were happy to be able to report our progress to the Board of Supervisors each month. There were not any change orders needed for this project and LMK finished on time,” said Daly. “Since we operate our own wastewater treatment plants here on our CSID campus, we are able to appreciate the reduction of inflow on a daily basis when our area receives a large amount of rain. No longer are we processing rain water inflow that used to manifest itself in Lift Station 1 due to leaking laterals and tree root laden sewer pipes. It was very important to CSID to have documentation and video of the entire project, start to finish. We are currently evaluating another Lift Station basin and anticipate beginning the camera documentation soon, and you can bet that we will opt for LMK.” “The significant amount of I/I reduction impacted other stations in the system and brought our utility management issues under control. Lift Station Number 1 pumps into a manifold force main, we have seen a reduction in adjacent stations run times as well. This further reduces stress on the pumps beyond this station. These reductions weren’t even part of the savings calculated. It’s just another benefit to the system for correcting excess infiltration,” said Seigfried.

“This is our largest lift station in the system and it was experiencing large amounts of infiltration; I didn’t think we would ever see the bottom of the station again. With the repairs performed, the pressures are down in the overall system and we haven’t had a call out on this station since we did the project,” said Dwiggins.

“The amount of groundwater infiltrating made it difficult to work in the system. For the most part, the mains were already lined; the water was tracking and also coming down the laterals ending up in the sewer. We had to isolate and pump down the section in which we were working. We could tell that we were having a big impact on the system because the more work we performed, the less bypass pumping we had to do. The system was drying up! In this station we reduced the flow by approximately 636,000 GPD. To put this into perspective, that’s about 32 swimming pools per day. All that water now remains in the aquifer instead of being pumped down the sewer,” explained LMK Pipe Renewal project manager Mark Gulyas.

The result is a conservation of our groundwater resources, protection of the environment, and a good return on investment. The District invested $1 million for this rehabilitation project, which was completed over a 10-month period. The District reports reduction of infiltration into its system by 232 million gals annually, with savings of $365,000 yearly. Even though years earlier a large part of the system had the mains lined, it wasn’t until the laterals were lined that the hidden value in the previous lining project was revealed. The payback for the entire project is just 2.6 years, and going forward the District’s investment will actually continue to save or earn CSID $365,000 each year for the life of the repairs.

Quality wins out every time when you consider the cost of resolving defects left behind by inadequate designs. Savings are waiting to be realized, this project is a win-win for many years to come.

John Rinehart is with LMK Pipe Renewal.