Finding I/I in Clearwater, Florida

The City of Clearwater, Florida, located along the Central Gulf Coast has been proactively performing a very successful sewer improvement program since 2022.

Much of the City’s system is more than 75 years of age. Like any collection system of that age, it was due for some upgrades.

Wastewater collection systems are a critical component of modern sanitation systems. They serve the vital purpose of transporting sewage from residential, commercial, and industrial sources to treatment facilities. This process relies on a well-maintained network of sanitary sewer pipes, manholes, force mains, lift stations, and wastewater treatment plants (WWTPs). These components ensure environmental safety and public health. Many of these aging collection systems in the US have far surpassed the expected useful life. Therefore, they must be assessed and updated in an efficient and cost-effective manner.

Advancements in technology, engineering, and software have led to improved means to thoroughly assess the existing infrastructure. These developments help in creating prioritized system improvements based upon sound risk-assessment protocols.

With an estimated budget for engineering and construction of approximately $110 million, Hazen and Sawyer has been leading this program. They rapidly employ advanced technologies to achieve their goals.

These include:

- CCTV digital video inspection of sewers, laterals and manholes (including artificial intelligence auto coding of defects)

- Smoke testing

- Dye testing

- Flow monitoring

This data is being utilized to plan, design, and create work orders for rehabilitating and replacing failing and/or leaking sewer systems.

Closed-Circuit Television (CCTV) Inspection

CCTV digital video inspection of sewers typically takes advantage of the only national standard in the US, Canada, and South America known as NASSCO Pipeline Assessment and Certification Program (PACP). The program also includes the Manhole Assessment and Certification Program (MACP) and Lateral Assessment and Certification Program (LACP). Below is a brief explanation about the PACP, MACP, and LACP programs.

NASSCO began establishing the PACP, MACP, and LACP programs in 2004. This program continues to evolve and now serves as the national standard for evaluating and documenting the condition of underground pipelines. By providing a consistent method for identifying and coding structural and operational defects, it enables professionals to compare pipeline conditions objectively. This facilitates prioritizing maintenance and planning rehabilitation efforts.

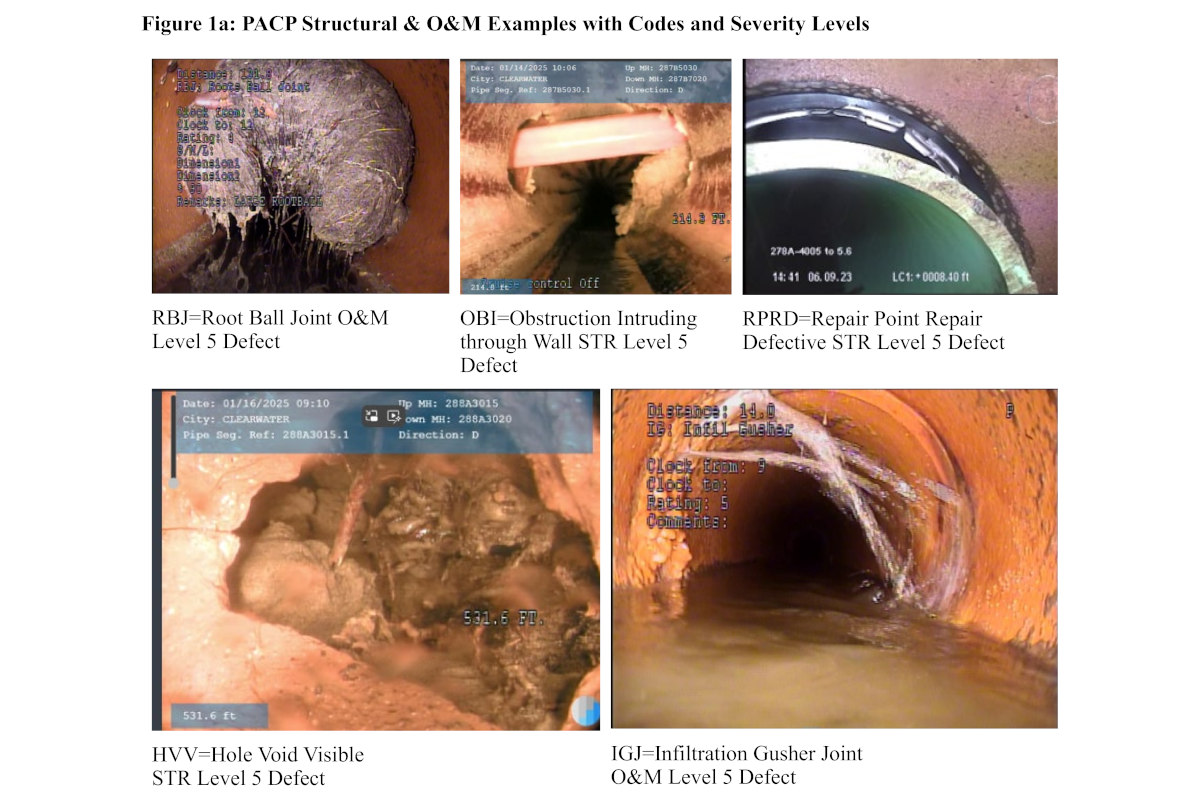

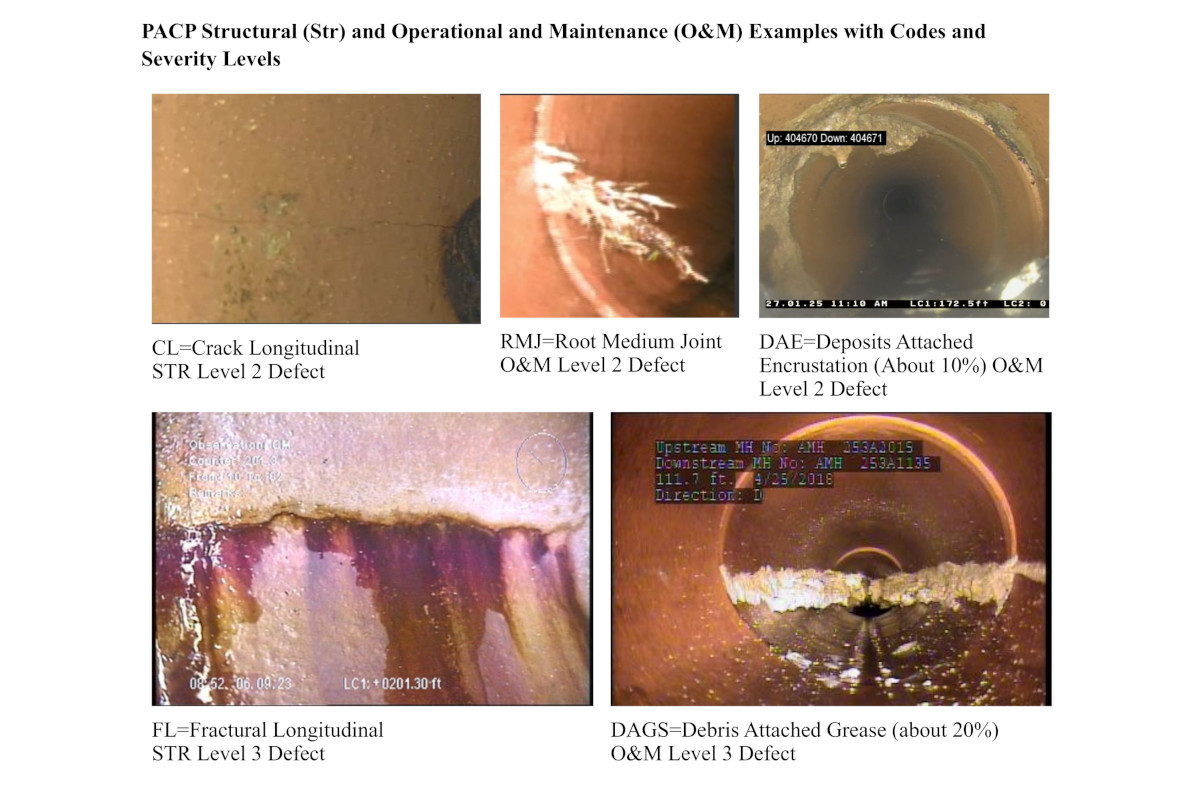

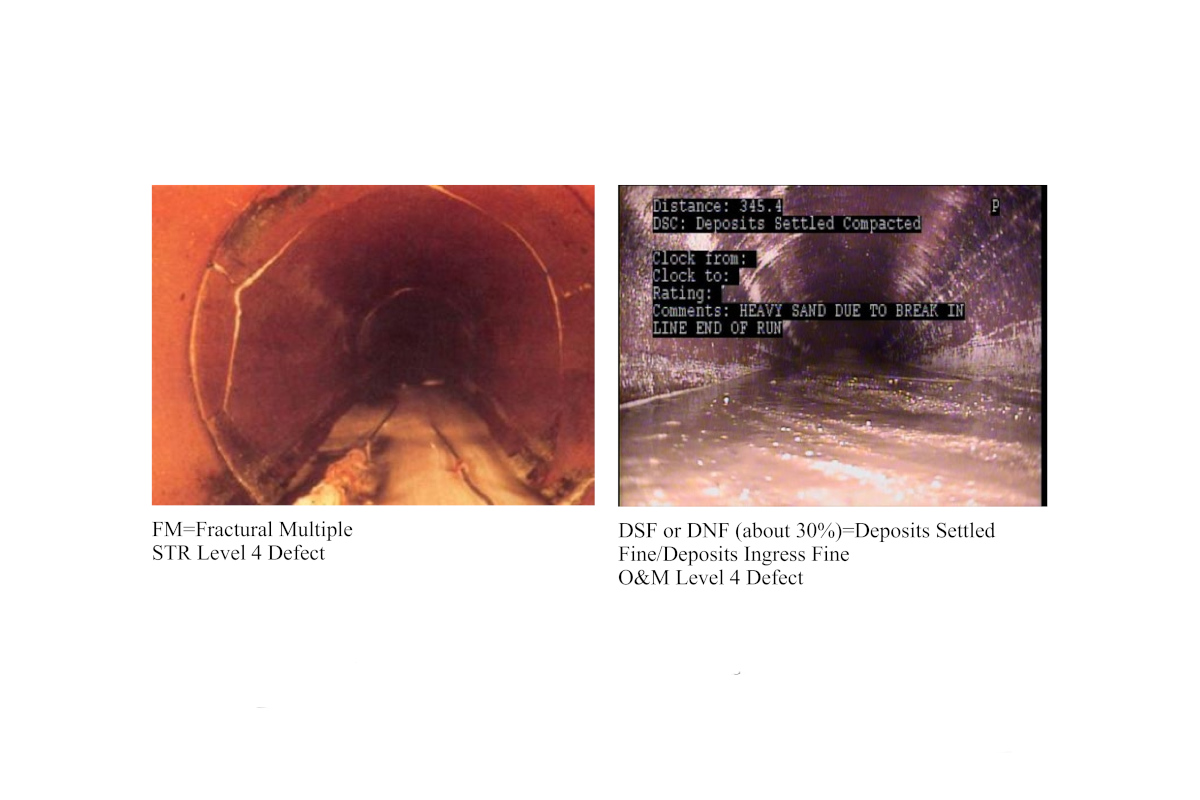

PACP sewer system defects are divided into four categories: structural, operational, and maintenance (O&M), construction features, and miscellaneous. The first part of the defect coding gives the defect category. The second part provides information related to the direction and location of the defect. The third part is often the severity of the defect.

Every defect is given a relative score from 1 (minor) to 5 (severe). Figures 1a and 1b illustrates some example photos from the City of Clearwater program.

By utilizing the PACP standards, municipalities and utilities can use PACP, MACP, and LACP software, databases, GIS, and digital videos. This facilitates informed decision-making regarding maintenance priorities and resource allocation. Such a standardized approach enhances the reliability of data across different inspections and inspectors. It contributes to more effective asset management and infrastructure planning.

Clearwater’s Sewer, Manhole and Lateral Inspection Procedures

- Contractor uses CCTV cameras to visually inspect sewer mains, manholes and laterals interiors.

- Pipe and manhole defects such as fractures, roots, grease, deposits, and infiltration are coded by operators. Artificial intelligence auto-coding and human reviews and edits also assist.

- Uploading digital video and digital databases to the cloud software for detailed analysis.

- Mainline sewer, manhole, and lateral inspection data are stored on one cloud-based software. This ensures unparalleled organization, efficiency, and engineering review. It helps in creating work orders for on-call contractors with annual construction contracts.

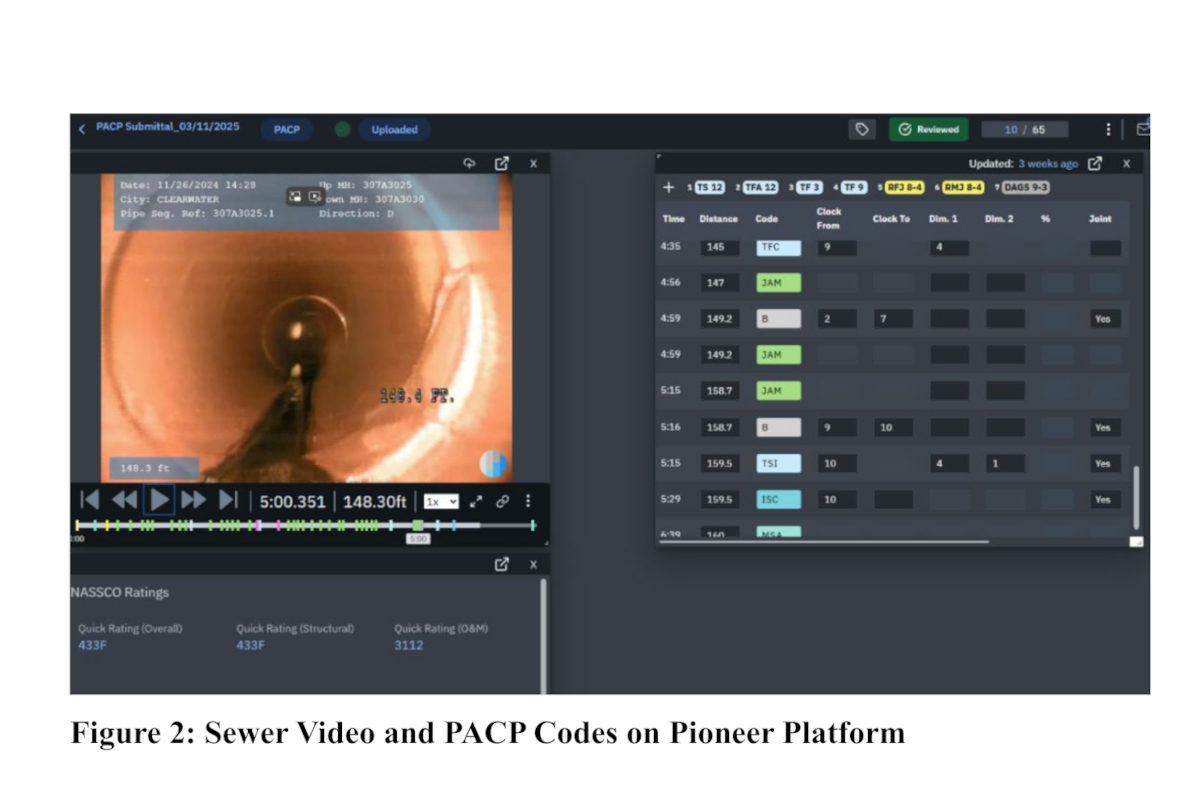

Below is an example figure from this software. It allows the engineers to efficiently review massive amounts of sewer, manhole, and lateral data to develop turnkey construction work orders.

Figure 2 illustrates the example of a sewer video on the software where sewer video along with PACP codes are shown. By knowing the codes and relative scores, engineers can “jump” right to that part of the video to make quick decisions.

Smoke Testing

Smoke testing is a cost-effective and efficient method for municipalities and utility companies to assess the integrity of sewer systems. It also allows for the identification of locations of potential infiltration and inflow from broken sewers, leaky joints, defective manholes, or illicit connections.

By introducing non-toxic, odorless artificially generated smoke into the system through manholes, maintenance holes or cleanouts. Technicians then observe where the smoke exits, pinpointing issues such as cracks, breaks, or improper connections. Additionally, if smoke enters a building, it may indicate defective plumbing, dry tap or a broken clean out.

Contractor’s and Engineer’s Workflow

The following is a summary of the collaborative process utilized for the Clearwater Collection System Improvement Program.

- Using PACP data, Engineer establishes the action required for each sewer segment including point repairs, CIPP lining or replacement.

- Construction Work orders are created in batches for Owner’s review and approval. These include: Point Repairs or Replacement, CIPP of Mainline Sewers, CIPP of Laterals, and Manhole Rehabilitation

- After getting Owner’s approval, work orders are sent to Contractors for cost estimates. Subsequently, the Engineer reviews the cost estimate and forwards it to the Owner for approval.

- After getting the Owner’s approval on estimate, Contractors are authorized to commence the work. It is overseen by the Engineer’s field inspectors.

- After completing work, Contractor updates the GIS dashboard with a cloud-based software application (see Photo 11). It reflects the completed work.

- Engineer reviews the post-rehabilitation video for compliance and payment.

Summary of Benefits

The City of Clearwater has developed and is currently implementing an extremely efficient and cost-effective sewer improvement program using the best available tools. They utilize technologies and methodologies to enhance the program. Improvements are being designed and constructed rapidly. This involves an incredible non-stop collaboration and communication between the city, engineer, contractors, and inspectors.

The benefits of this unique program may not be apparent to most residents, businesses, snowbirds, and visitors. Yet, these sewer system upgrades reduce infiltration and inflow (I&I) and reduce sanitary sewer overflows (SSO). This ensures adequate flows to WWTPs, which increases the lifespan of sewers, manholes, and laterals. It also prevents regulatory fines and consent orders and helps meet regulatory requirements. This is an efficient use of taxes and user fees and it improves the image from the residents and businesses. The approach using trenchless technologies helps prevent road closures as well.

Additionally, the use of technologies such as GIS, web portals, and dashboards have enabled municipalities to become more efficient and organized. Most importantly, it helps them become proactive with inspecting, maintaining, and replacing these critical assets.

John Schroeder, P.E., is associate vice president at Hazen and Sawyer. Dhara Mody, P.E., is a civil engineer at Hazen and Sawyer. Michael Vacca is Public Utilities Water & Sewer Infrastructure division manager with the City of Clearwater, Florida. Samantha Myers, P.E., is a mechanical engineer with the City of Clearwater, Florida.