Controlling Chaos – Emergency Sewer Bypass Execution

This article outlines the essential steps for establishing a safe and effective emergency sewer bypass, transforming potential chaos into a controlled, efficient response.

Sewer failures are emergencies no one wants. In the rush to contain the inevitable overflow, safety and strategic planning can easily be sidelined. But a successful sewer bypass isn’t just about reacting; it’s a calculated operation, a blend of science and practical expertise, crucial for safeguarding public health and infrastructure.

Sewer Bypass Safety Plan

Containment might be the immediate goal, but safety must never be an afterthought. It is paramount to stop, exercise caution, and ensure a proper site-specific safety plan is in place. This plan should not only include the proper PPE but also ensure there is lighting, proper lifting equipment, and fall protection when working around open manholes or open structures. The goal is to ensure everyone working on-site has situational awareness and returns home safely.

Diversions

Before committing to a full bypass, ask: is it truly necessary? A thorough assessment of the collection system is crucial. This can be accomplished by leveraging the GIS data to determine if there are any upstream diversions. In emergencies, diversions can often be many miles upstream, which, when activated, significantly reduces the scope of the emergency bypass. If no diversions are available, look for parallel sewer lines that can safely convey the flow around the work environment to reduce the bypass scope.

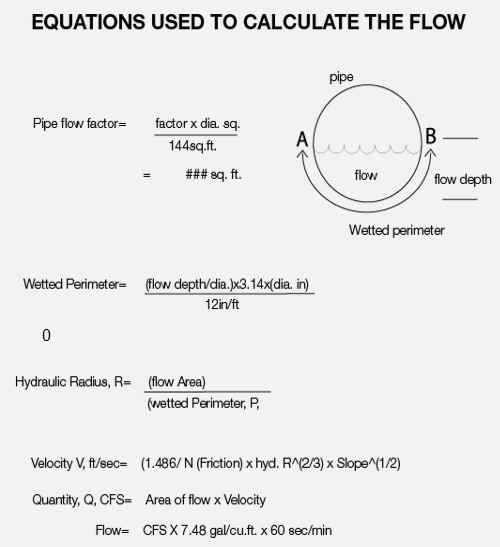

Determining Flow

Once a pumping system is installed and operational, you are committed. So, the sizing of the system is critical to the success or failure of the pumping project. Therefore, determining the flow is crucial to the bypass design. Flow data can be easily accessed in collection systems with treatment plants just downstream of lift stations. However, on systems without flow data available, you can take the diameter and grade of the sewer to be bypassed and determine the flow with the manning equation. As with most emergencies, plan for a worst-case scenario because there is a reason why there is an emergency.

Below are a few examples of flows in smaller gravity sewers based on full pipe:

- Max capacitates in sewers at a .5% grade:

- 8-in. Sewer = 384 GPM

- 10-in. Sewer = 696 GPM

- 12-in. Sewer = 1,131 GPM

- Max capacitates in sewers at a .1% grade:

- 15-in. Sewer = 917 GPM

- 18-in. Sewer = 1,491 GPM

- 24-in. Sewer = 3,212 GPM

The grade can vary the design flow. These are examples based on averages. The grade and material (Coefficient) will increase or decrease gravity flow.

Access Is Everything

Perhaps the crux of any sewer bypass is not the bypass itself but the available access to implement it. The design flow is a key element and will dictate the amount of access required.

To put it simply, More Flow = More Access Requirements.

Suction Access

The location of the suction manhole will be, in most cases, one line segment upstream from the work environment. This location plays a key role because you can achieve a limited amount of flow through a 21-in. standard manhole. For smaller diameter sewers, this does not play a factor; however, on flows greater than 4,000 gpm, it is difficult to utilize a single manhole without modifications to install a bypass system with redundancy. Therefore, multiple suction locations may be required, or the manhole cone may be pulled to provide access for the multiple suction tubes.

Suction Depth

The depth of the sewer dictates the bypass design at the suction location and the size in which to install suction tubes and/or submersibles. While also considering the proper surcharge levels to reduce cavitation, and the appropriate spacing to reduce suction interferences. Auto-Priming Centrifugal Pumps are optimal with a static suction lift of less than 15 ft. For depths greater than 15 ft, thought needs to be put into the suction location design. Can the flow be surcharged without impacting the collection system upstream? Are the manhole depths upstream shallower? If not, then the pumps may need to be benched down to reduce the static suction lift. If this is not possible, then submersible pumps may require modifications to the suction location to allow for submersible access, depending on the design flow.

Discharge Pipe Routing

We have found the impact of the discharge route will vary in difficulty depending upon its impact on the community. The design flow of the bypass will dictate the pipe size, which may require fusion of HDPE Discharge. Larger flow emergency bypasses will require staging areas for pipe and heavy equipment. Also, you should factor in if there will need to be any easement clearing for bypass discharge pipe route or trenching for roads. To expedite the containment of the emergency, a smaller sewer bypass can be implemented with road closures while the main bypass access is being constructed. The discharge pipe route may also be required to exit the easement to avoid impacting the community. The Google Earth tool is great for exploring different discharge pipe routes for easy access and limited community impact.

Discharge Access

The size of the discharge manhole does not have as big an impact on the design flow as the suction manhole, but it does have an impact on bypass design flows greater than 8,333 gpm. In that, a standard 21-in. frame limits the diameter of your discharge pipe, which is typically 18-in. or 24-in. HDPE. For flows greater than 8,333 gpm, it is advisable to modify the manhole to accommodate multiple discharge pipes or a single larger diameter. On some occasions, manifolds have been utilized to combine multiple discharge pipes into a single line, which will fit into a standard 21-in. frame; even though it works, it will add additional time to the emergency response.

Plug Access

Very similar to the suction access in that on larger diameter sewers, big pipe plugs do not fit through a standard 21-in. frame. The only size you can fit through a 21-in. opening is a 20- to 36-in. plug. This barely fits, so put some thought into the pipe plug location because you do not want to remove the bypass just to install the plug. Having a secondary access point downstream is easier and safer to install. Installing is easy, but removing can be a bit more challenging; therefore, plan accordingly.

Contingencies

Let’s face it; stuff breaks on sewer bypasses: pumps rag up, floats get sucked into pumps, seals fail, and impellers get eaten. Discharge pipe can be compromised by several variables outside the realm of control, which is why proactive contingency planning is essential.

Pump Redundancy

It is not a matter of “if, but when” you are going to have an issue with a bypass pump. Always plan for the worst-case scenario and have a backup pump installed in the system that is ready to activate. Additionally, ensure all the pumps are tied into the bypass discharge with isolating check valves in case a pump goes hard down and needs to be replaced while the system is in operation.

Fueling

Plan accordingly. It is better to have too much fuel than no fuel. If the project is going to run for a long duration or is a large-diameter bypass, have enough fuel on-site in secondary tanks to run the primary pumps for 48 hours. Have a secondary fuel supplier available should the primary fuel supplier miss a fuel drop.

Spare Parts and Tools

Many items that are utilized in bypasses are not readily available at local big box stores. Therefore, always ensure that critical spare parts and tools are on-site. In addition to spare parts, have the tools sized correctly for the flange bolts. Lastly, if the discharge pipe is HDPE, an HDPE repair clamp should be on-site.

System Operation

The most crucial element to a successful sewer bypass is the operation. Remember that this is a temporary pump station; even with a backup pump, the system should be monitored 24/7. As with any temporary systems, floats get hung up, pumps rag, radiators overheat, and a litany of other items can affect the pump system. Whereas, with trained operators, response time to issues can be greatly reduced and mitigated before they turn into larger issues. Ensure you have trained people with the proper tools, emergency contacts, and procedures should there be a failure.

Emergency sewer bypasses demand a blend of swift action and meticulous planning. By prioritizing safety, accurately determining flow rates, and access and contingencies, utilities can transform potential disasters into well-managed operations.

By implementing these best practices, professionals can mitigate risk, protect their communities, and uphold the integrity of essential infrastructure.

Ladd Gould is strategic customer manager Sunbelt Rentals, Pump Solutions.