By the Numbers:

March 1, 2009

The Phoenix Expansion project is a 259-mile expansion of a natural gas pipeline, owned by Transwestern Pipeline Co., Houston. The expansion is designed to help supply the fast-growing energy demands of customers in the Phoenix area, specifically Maricopa County.

The Phoenix Expansion project is a 259-mile expansion of a natural gas pipeline, owned by Transwestern Pipeline Co., Houston. The expansion is designed to help supply the fast-growing energy demands of customers in the Phoenix area, specifically Maricopa County. Maricopa County is one of the fastest growing counties in the United States. According to the U.S. Census Bureau statistics, the population of the county rose more than 22 percent from 2000 to 2006. And that growth is expected to continue.

While much of the pipeline expansion route, which extends from Transwestern’s mainline in Yavapai county to just south of the Phoenix area, requires open-cut pipeline construction techniques, a large portion does utilize trenchless technology such as horizontal directional drilling (HDD), auger boring and pipe ramming.

One segment in particular called for an HDD crossing of the Gila River west of Phoenix. The Crossing Company, Nisku, Alberta, Canada, was called in to perform the high-profile bore that included the installation of a 36-in. steel pipe over three-quarters of a mile long. Adding to the mystique of the project were unconfirmed stories of several, failed directional drilling attempts to cross the river in the past. To successfully complete the project, crews would call on years of HDD experience, as well as a pipe ramming technique to help get the project off to a good start.

According to Ryan MacLean, The Crossing Company president, being contracted for the project happened quickly. “This came at the last minute. We went down and had a look at the project and within a month or so we had our equipment on site,” he said.

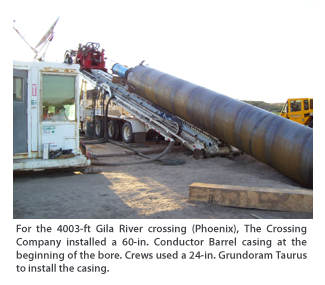

For the Gila River crossing, crews utilized a 660,000-lb directional drill rig and a Grundoram Taurus pneumatic pipe rammer from trenchless equipment manufacturer TT Technologies, Aurora, Ill.

The Crossing Company was established in 1997. After seeing the need for HDD services in western Canada, a group of oilfield service veterans came together to fill that gap. Shortly thereafter, the company acquired its first directional drilling rig, a 300,000-lb unit. Within the next two years, three more rigs were added. The company continued its steady growth and today employs 11 drill rigs ranging in size from 80,000 to 660,000 lbs. In a little over a decade, The Crossing Company has amassed an impressive resume.

“When we started, we were able to combine industry-leading personnel with equipment specifically designed for the Canadian climate to complete some of the most challenging projects in Canada,” MacLean said. “We’ve grown beyond that now and travel throughout North America. One of the biggest challenges with the Gila River crossing was adjusting our equipment for the temperatures of Arizona.”

24 Hours a Day, 7 Days a Week

Safety is a major area of focus for The Crossing Company. “Our objective is to lead the HDD industry in terms of promoting health, safety and environmental responsibility,” MacLean said. “Our HSE program includes training our employees in behavior-based safety, including courses such as, Job Observation and Hazard ID, Leadership Training and Incident Investigation. We understand the value that a strong safety culture brings and will maintain a leadership role in developing and improving equipment, programs and attitudes. I believe that safety is something that needs to be reinforced by all levels of our organization.

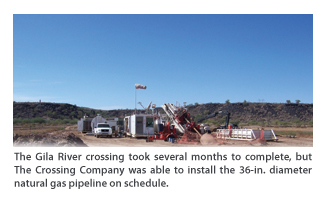

“When we started the Gila River project in August [2008], we ran 12-hour shifts. We did that for about one month. Then we went to 24-hour shifts for September, October and November.”

Running non-stop, seven days a week takes a great deal of focus, commitment and communication to keep everything running smoothly and safely. On the jobsite, crewmembers are thorough and diligent. “Tailgate” safety meetings are held at the beginning of each shift and equipment is closely monitored. But according to MacLean, “That’s just part of the job.”

Running non-stop, seven days a week takes a great deal of focus, commitment and communication to keep everything running smoothly and safely. On the jobsite, crewmembers are thorough and diligent. “Tailgate” safety meetings are held at the beginning of each shift and equipment is closely monitored. But according to MacLean, “That’s just part of the job.”He said, “It’s typical for us. Almost all of our projects up here are 24 hours a day, so we’re accustomed to it. There is much efficiency realized while working in this manner. But it also comes down to tight schedules and meeting deadlines. On this project we had a request from our customer to get the job done as quickly and efficiently as possible.”

Maintenance also plays an important role in keeping a project operating 24 hours a day. MacLean said that while equipment goes through scheduled checks and inspections, regular maintenance is an ongoing process that happens everyday, and everyone shares in that responsibility. The results are evident. The company’s historical statistics show that they have experienced less than one percent overall downtime — a fact MacLean is proud of.

But of all the challenges, heat was one of the toughest on this particular project. “This project is interesting because the challenges for our company were different than other companies working regularly in that part of the country,” MacLean said. “Our equipment is designed to handle extreme cold weather applications. It’s housed in cold weather/oil field buildings. For this project, maintaining the equipment in heat was one of the biggest obstacles.”

The Project

To get this project started on the right foot The Crossing Company employed one of several HDD-assisted techniques developed by TT Technologies and its partner contractors, a Conductor Barrel installation. The Conductor Barrel is a patented-process and differs slightly from the other HDD-assisted methods in the sense that it deals with the actual drilling aspect of the project rather than pullback or recovery.

“The concept behind the Conductor Barrel is creating a clear pathway through poor soil conditions so that drilling can begin in more preferable soil conditions,” said TT product specialist Rick Melvin. “The success of a drilling operation can often be determined right at the start. If drilling does not begin in soil that is conducive to drilling, the success of the entire project can be put in jeopardy. Loose, unsupported soils are prime candidates for the Conductor Barrel method. And that was definitely the case in Arizona.”

During the conductor barrel process, casing is rammed into the ground, at a pre-determined angle, until desirable soil conditions are met. The spoil is removed from the casing with an auger or core barrel. Drilling proceeds within the casing in the desirable soil conditions. In addition to assisting drilling operations at the start, the conductor can also serve as a friction-free section during pullback. In addition, the conductor barrel can prevent situations in unstable soils where drilling fluids under pressure force their way into waterways or wetlands, acting in a similar fashion to containment cells.

During the conductor barrel process, casing is rammed into the ground, at a pre-determined angle, until desirable soil conditions are met. The spoil is removed from the casing with an auger or core barrel. Drilling proceeds within the casing in the desirable soil conditions. In addition to assisting drilling operations at the start, the conductor can also serve as a friction-free section during pullback. In addition, the conductor barrel can prevent situations in unstable soils where drilling fluids under pressure force their way into waterways or wetlands, acting in a similar fashion to containment cells.The soil conditions at the Gila River crossing prompted Crossing Company crews to install the Conductor Barrel. In order to accommodate the necessary reaming for the project and ultimately the 36-in. pipe, a 60-in. diameter casing was used for the Conductor. To ram the casing in place, crews used a 24-in. diameter Grundoram Taurus pipe rammer.

While a 60-in. casing may seem large for this application, MacLean said looks can be deceiving. “When you’re pulling a 48-in. product line into a 60-in. casing, it’s really not that much space,” he said. “The reamers that we use are very large and heavy so you want to give yourself the best chance at pulling this tooling into the conductor without incident. It also gives you room in case you need to upsize to another reamer, a 54-in. for example.”

To install the conductor barrel, the drill rig was positioned at a pre-determined angle. Crews then welded together the first two 20-ft sections of 60-in. casing. A fabricated cutting shoe was then attached to the front of the casing. The welded section was then positioned on the rack of the drilling rig and prepped for ramming.

Next, crews used the crane to place the Taurus ramming tool in position and made the connection between the tool and the casing. A series of ram cones were used to reduce the overall diameter from 60 in. to the 24-in. connection needed to accommodate this particular tool.

The ramming tool made quick work of this installation advancing the 60-in. casing at approximately 30 ft per hour. The total length of casing installed on the Gila River project was 147 ft.

“The angle of the conductor barrel was 18 degrees. The steeper the angle the quicker you’re able to advance through the problematic zones,” Melvin said. “The spoil from the conductor barrel was cleaned out with a fabricated auger system that attaches to the drill rig.”

Once the spoil was cleaned out, crews were ready to begin the pilot bore.

The Pilot Bore

The Crossing Company crews began with 9 7/8-in. pilot bore, through the 60-in. conductor barrel on its way to the other side of the river some 4,003 ft away. Each stem of 6 5/8-in. drill pipe utilized on the 660,000-lb rig is 30 ft long. The pilot bore took approximately two weeks to complete.

After the pilot bore, crews focused on reaming. Four ream passes were made over the course of the next 48 days. The first pass was an 18-in. forward ream. The second was a 26-in. ream. That was followed by a 36-in. ream and finally 48-in. reaming pass.

After the pilot bore, crews focused on reaming. Four ream passes were made over the course of the next 48 days. The first pass was an 18-in. forward ream. The second was a 26-in. ream. That was followed by a 36-in. ream and finally 48-in. reaming pass.After the reaming process, crews attached the first section of 36-in. O.D. product line for pullback. The pipe was pulled back in three sections due to space limitations. Because of the precise welding requirements, product pullback was successfully completed without incident over one and a half days.

Results and Reaction

The Gila River HDD project was successfully completed on Nov. 26, 2008, just before Thanksgiving. As a result of the overall scope of the project and its technical nature this proved to be a significant achievement for all parties involved.

MacLean added, “We are extremely pleased with all aspects of this project including execution, safety and schedule. Many people thought this HDD could not be done, but through thorough planning and execution we were able to prove otherwise,” MacLean said. “This accomplishment was a direct result of the dedication and hard work of our experienced employees, our ability to rely on companies such as TT Technologies and the tremendous support from our client.”

Jim Schill is a technical writer in Mankato, Minn.