92-in. Stormwater Pipeline CIPP Rehab in Englewood, Colorado

The City of Englewood, Colorado partnered with Insituform Technologies to rehabilitate a 2,555-ft section of the Oxford Street Storm alignment using cured-in-place pipe (CIPP).

The project addressed major structural and hydraulic issues in deteriorating 92-in. and 78-in. corrugated metal pipelines. Key challenges included balancing design and constructability, limited access points, over-the-hole wet-out installation, a diameter transition, mitered bends, and stringent cure water discharge requirements. Collaboration among stakeholders was critical to overcoming risks and completing the project successfully.

Background

Built in the 1970s after the 1965 South Denver flood, the Oxford Street Storm alignment had suffered multiple sinkholes (2015–2019), signaling the end of its design life. Assessments in 2021 by Lithos Engineering (now GEI Consultants) confirmed severe deterioration. CIPP was selected as the most cost-effective, sustainable rehabilitation method.

After another sinkhole in 2023, the City fast-tracked the South Englewood Outfall Flood Reduction Site A project. Insituform Technologies won the contract in August 2023 and began work that fall.

Major Challenges and Solutions

Structural Design of the CIPP Liner

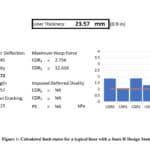

The design had to meet structural requirements while preserving flow capacity, limiting liner thickness to 2.5 in. It also needed to withstand AASHTO H-20 live loads and internal pressure up to 10 psi.

To meet these conditions, Insituform used fiberglass reinforcement, reducing liner thickness by roughly 25 percent while maintaining strength. This innovation lessened liner weight and improved installation ease.

Limited Access Points

Only three existing manholes and one excavated pit were available. Insituform optimized installation by using the excavated pit for an over-the-hole wet-out process, enabling two long installation shots (600 ft and 1,500 ft). This reduced excavation, cost, and surface disruption.

Over-the-Hole Wet-Out Process

Because fully wet-out liners would exceed transportation limits, Insituform performed on-site wet-out. The dry liner was saturated with resin at the access point and inverted directly into the pipeline using a water inversion and curing method, ensuring uniform pressure and consistent cure temperature.

This process allowed for two efficient blind-shot installations and precise liner placement.

Diameter Transition

The pipeline transitioned from a 92-in. polymer-lined corrugated metal pipe to a 78-in. concrete pipe. A custom-manufactured transition was sewn into the liner, minimizing wrinkles and maintaining fit.

After curing, the remaining annular space was grouted by Cardinal Coatings to ensure structural integrity and prevent water migration.

Mitered Bends at the Outfall

Two sharp bends (62 degrees and 42 degrees) near the South Platte River created a high risk of liner twisting or failure. Insituform collaborated with engineers to modify the approach: the CIPP liner was installed through the 42-degree bend, and Cardinal Coatings applied a geopolymer spray liner through the 62-degree bend.

The geopolymer formed a smooth interior and provided structural reinforcement with an average thickness of 2.75-in.

Cure Water Testing and Discharge Requirements

Environmental regulations prohibited discharging the cure water directly into the South Platte River. All discharge had to meet strict quality limits set by South Platte Renew (SPR), the local wastewater treatment authority.

Insituform’s solution included:

- Cooling the cure water to 104F and collecting it in on-site tanks.

- Filtering it through carbon units to remove styrene and other compounds.

- Independent lab testing to confirm compliance with permit standards.

- Controlled discharge at 100 gallons per minute to ensure safe dilution.

This process successfully protected SPR’s biological treatment systems.

Results and Outcomes

Awarded in September 2023, the project began construction in January 2024. Despite multiple snow delays, substantial completion was achieved in just 90 days (March 30, 2024). The final cost was $3.45 million, with no formal change orders required.

Close collaboration between Insituform, engineers and city officials transformed an initially risky design into a model of innovative problem-solving. The combination of CIPP and geopolymer lining extended the service life of the pipeline, minimized environmental impact, and demonstrated how modern trenchless technologies can address complex infrastructure rehabilitation needs.

Conclusion

Through creative engineering, proactive collaboration, and adherence to environmental standards, the City of Englewood and Insituform Technologies completed one of the region’s most challenging stormwater rehabilitation projects on time and within budget. The project’s success underscores the potential of integrated trenchless technologies and collaborative risk management to deliver sustainable infrastructure solutions.

Brad Conder, P.E., is commercial manager with Insituform Technologies LLC.

- How to Inspect and Assess Lateral Sewer Pipes

- Spotless Sewer Lines Play a Key Role in Lining Success

- How to Develop a Cost-Benefit Analysis for Pipeline Rehabilitation vs. Replacement

- How to Apply ASCE MOP 145 to Gravity Lining Projects

- How to Prepare and Trowel-Apply for a Manhole Rehab Project

Next Up

2026 Microtunneling Short Course | May 5-7, 2026 | Scottsdale, Arizona | Learn more