The Challenge of Manhole Infiltration in Napa

Estimates show there are more than 20 million sanitary sewer manholes in the United States. Twenty million chances for cracks, damage, and overall structure degradation due to environmental factors like soil shifting or erosion, water infiltration from high groundwater levels, inadequate gaskets or seals, and general corrosion of materials from age. Twenty million manholes that serve a vital role in urban infrastructure access across the nation.

Many of these issues can be mitigated with regular maintenance, monitoring, and timely repairs. However, because manholes are often underground and out of sight, out of mind, they are sometimes neglected until these problems become serious and a danger to the community.

Of those 20 million manholes, 5,651 of them reside in one of the world’s most famous wine regions with stunning countryside views — Napa Valley, California. Napa Sanitation District (NapaSan) provides wastewater collection, treatment, and disposal services to the residents and businesses in the City of Napa, Silverado Country Club, the Napa County Airport, and several adjacent unincorporated areas.

NapaSan’s Assets

- Area of service: 21 sq miles

- Lateral lines maintained: 27,000

- Manholes: 5,651 – precast and brick

- Miles of sewer mainlines: 270

- Pipe size: 4 to 66 in.

- Sewer connections: 36,000 residential and business connections

NapaSan has long been a proactive force in maintaining its wastewater collection system. With a commitment to ensuring efficient service and long-term sustainability, the District has made aggressive progress to rehabilitate its aging infrastructure.

A significant element of NapaSan’s strategy has been its program to rehab or replace 2 percent of its mainlines and laterals every year, with substantial success in addressing inflow and infiltration (I&I) issues. However, even with more than 25 percent of the system rehabilitated, NapaSan continues to face significant water challenges where I&I causes a massive increase in flow to the collection system and facilities.

Manhole Woes in Wine Country: Combatting Inflow and Infiltration

Inflow and infiltration is the unintended flow of groundwater through cracks, joints, or defects into the wastewater collection system. For NapaSan, this issue has been a major concern, especially during rainy periods. Typically, the District sees dry weather flows of around 6 million gallons per day (mgd), however during heavy rainstorms, this number can increase dramatically. The most recent storm in early February 2025 saw flows skyrocket to almost 60 mgd — a tenfold increase! This uptick in flow places tremendous pressure on our infrastructure and treatment facilities, increasing treatment costs and potentially straining system capacity.

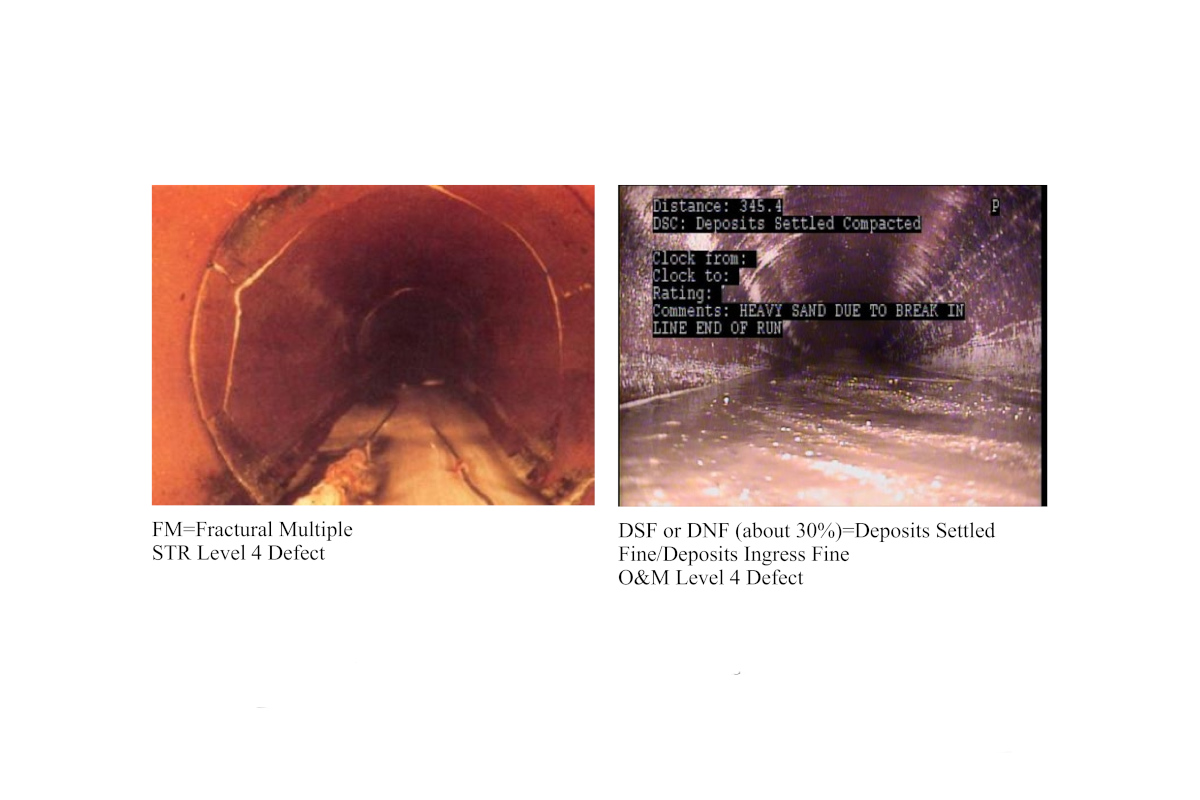

A key area of concern for NapaSan has been its manholes, which have become significant entry points for infiltration. Manholes, particularly those in areas of high groundwater saturation, are prone to cracks and defects that allow water to enter the system, exacerbating I&I issues. NapaSan has been addressing this through its ongoing rehabilitation efforts, replacing or repairing sections of the system annually. However, it became evident that additional measures were necessary to curb the infiltration further and reclaim valuable system capacity.

The Challenge of Timely Grout Injection

For NapaSan, injection grouting has been identified as an effective method to seal cracks and defects in manholes, preventing groundwater from entering the system. By injecting grout, the infiltration can be stopped almost immediately. NapaSan initially relied on external contractors to perform all grout injection services for its manholes, but a significant challenge arose: the need to act quickly and efficiently while the infiltration was still active.

If the contractor could not arrive in time or had a full schedule ahead of them, NapaSan missed the chance to seal the defects and halt the infiltration while still active. With such a tight timeframe, NapaSan realized it needed to take a more hands-on approach to grout injection.

Bringing Manhole Grouting In-House

After recognizing the need for a quicker, more responsive solution, NapaSan decided to bring grout injection services in-house. The decision was bolstered by NapaSan’s existing capabilities as they already had a trained confined space entry and rescue team, which could safely handle the work in the challenging environments of manholes. Coupled with a motivated repair crew eager to tackle the challenge, the move to handle grout injection in-house was a logical next step.

NapaSan worked closely with a reputable local contractor that had previously provided successful grout injection services using Avanti International’s polyurethane injection grout products. After evaluating the effectiveness of the grout materials used by the contractor, NapaSan opted to continue the use of Avanti’s grouts, a trusted solution that delivered positive results in prior projects. “The decision to continue using Avanti for in-house work was straightforward, as the grout had proven to be reliable and effective in addressing infiltration” says Seth Rossi, Collection System Manager. “The NapaSan team attended a hands on, on-site training over the safe and proper use of injection grout and the equipment for manholes. We continue to contract out larger rehabilitation projects for our system, but it is beneficial to be able to take on some of these projects in-house so we are able to be proactive” says Rossi.

Results and Impact of Grouting

The ability to quickly address infiltration has had a direct impact on NapaSan’s system capacity.

One of the key successes of the program was grout injection performed during an early February 2025 rainstorm. NapaSan grouted 11 manholes, addressing infiltration with a conservative average infiltration rate of 13 gallons per minute (gpm) per manhole. Given that the infiltration rate is heavily dependent on groundwater levels, the impact of grout injection varied. Before grouting, infiltration slowed or stopped within a few days as groundwater levels recede, while in other cases, the effects can last longer—sometimes tapering off after two weeks of dry weather.

As a result of sealing manholes, NapaSan has reclaimed valuable treatment capacity, reducing the overall strain on its system. The program has also contributed to lowering treatment costs. “Treating wastewater is expensive, and with the cost to treat 1,000 gallons of wastewater averaging around $3.00, reducing unnecessary flow translates into significant cost savings over time” says Rossi.

Moving Forward

NapaSan’s in-house grout injection program is still in its early stages, but it has already demonstrated its effectiveness in addressing infiltration during rain events. While many manholes will only leak during certain conditions, NapaSan has the flexibility to act quickly when needed, thanks to its trained team and timely grout injection capabilities.

Looking ahead, NapaSan plans to continue expanding its grout injection efforts. With a large portion of the system’s infrastructure already rehabilitated and fewer brick manholes left to replace, NapaSan is well-positioned to maintain its commitment to reducing I&I and maximizing system efficiency. The success of this in-house program provides a model for other wastewater systems facing similar challenges and highlights the importance of adaptability and innovation in maintaining infrastructure.

As NapaSan continues to improve its infrastructure and tackle I&I issues head-on, the District remains dedicated to its goal of providing high-quality, cost-effective wastewater services to the Napa community and its 3.7 million visitors each year.

Jessica Williams is marketing manager at Avanti International.