Some Good News from the Pressure Pipe World

We are often inundated with bad news whether it be in print or on television. However, I have some good news to share with all water and wastewater professionals! New, vetted technology and more competition is here!

The niche sector of pressure pipe inspection, maintenance and rehab has seen plenty of innovation this century. Some aspects have been relatively stagnant due in part to patent protections or the slow march of research and development. Over the past couple of years there have been promising new startups founded. New technology has been brought to market at a dizzying pace.

Let’s take a look a few of these advancements.

In-Line Inspection Advancements

You may have noticed that several in-line inspection balls have entered our market over the past five years, each with unique capabilities. Ball devices not only find leaks and gas pockets, but also offer combinations of pressure data, magnetic anomaly detection, and even sonar/debris information.

As micro sensors become more readily available and inexpensive, leak detection/reconnaissance balls have become more commonplace. Last year, one new ball device was invented that inspected a single, record-breaking stretch of 101 miles in a 72-in. raw water transmission main in Corpus Christi, Texas. That project won Corpus Christi Water the “Asset Management Project of the Year” at a recent construction tradeshow. Not only was the battery capacity developed to travel the long distance, but trackability and neutral buoyancy ensured inspection success.

Near Field Testing

In early 2022, the patent for electromagnetic ‘Near Field Testing’ for wire and bar break detection in concrete pressure pipe expired. Since then, new providers have entered the market to inspect PCCP and Bar-Wrapped Pipe.

The method of tool inspection can be piloted with humans (out of service) or free-swimming (in service). Last year, the second commercially available free-swimming tool was launched. This, in itself, is good news. However, this new Near Field Tool is also capable of integrated sonar for debris and gas pocket detection while collecting wire/bar break integrity data. It is also smaller and more nimble for better conveyance. For the first time ever, CCTV cameras and acoustic sensors for leak and gas pocket detection have been integrated on board of an electromagnetic tool. This eliminates the need for a separate acoustic inspection. It can better pinpoint the location of leak and gas pockets due to the electromagnetic tool’s capability to detect joints. Additionally, the tool’s trackability from outside of the pipe adds value.

Remote Field Testing

Remote Field Testing is another well-established electromagnetic inspection technique for pressure pipes, specifically for cylinder assessments. Starting this year, Remote Field Testing or Advanced NDT is now practiced by multiple technology providers. Advancements in scan speed, available data sets, and data processing methods are all areas where improvements are being made.

Oil and gas tools that have been relegated to that industry are now being introduced into the water and wastewater space. Eddy Current smart pigs that are compact and even reusable in different pig sizes are now available. Caliper smart pigs that can measure and locate blockages and deflections are available. Even XYZ mapping smart pigs are now being used to locate and measure pipe bends and bend locations. Granted, our infrastructure still often lacks pigging ports and full-bore valves. However, that is slowly getting better as outreach and education is increasing. This involves technology firms, contractors, and design professionals.

External Inspection Advancements

As water becomes scarcer in several regions and population increases, dewatering and interrupting service becomes more difficult, if not impossible. Even where pipeline service can be interrupted, bellies can collect water that are difficult to eliminate. Valves often do not perform well and allow leaks, which also makes out-of-service inspections challenging. There have been external acoustic techniques available for several years. However, in general, they have provided averages over given distances often longer than a pipe segment. Some required inducing a water hammer for inspection.

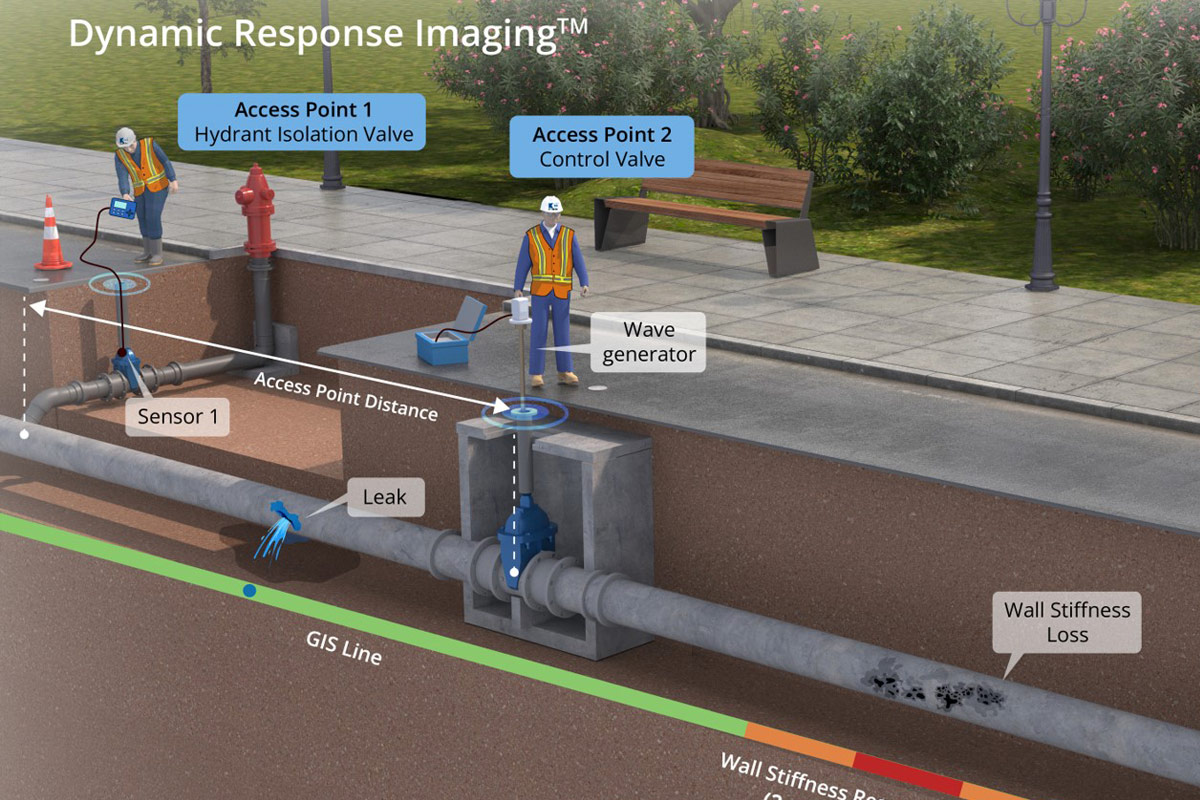

A new technique has recently emerged that uses vibration and acoustic induction to inspect pressure pipes for loss of stiffness. This is a direct indicator of a pipe’s residual strength. Contact with the pipe must be made at three points (existing appurtenances or potholes). This technique can be applied on all materials (ferrous and non-ferrous). What is unique or new is the resolution, which can be as good as 2.5 times the pipe diameter. The vibration and sound is harmless and the method is completely non-invasive. So, no shutdowns, threats to water quality, nor water hammers occur. Case studies with validations have been performed, and additional case studies are under way.

New Developments in Rehab

This year in the pipeline rehab space, a new spray-in-place pipe (SIPP) resin became available that allows pipe reinstatement within the same day. The resin is free from BPA, VOC, PFOS, PFOA and has NSF approval. Well-established FFRP (Flexible Fabric Reinforced Pipe) already obtained NSF approval, but just recently was granted an ASTM designation.

Ancillary Maintenance Technology

Another intriguing development is a patented, British seized valve release technology that came into the United States this year. This service utilizes smart hydraulic actuator operations, which calculate the correct direction and amount of cycles for all sizes and types of valves. This tool uses Hooke’s Law to avoid breaking a valve.

Pressure Pipe Progress

The theme of the progress that is being made is more providers, better resolution, more data sets, and less intrusive technologies. This progress will help industry professional efficacy. Therefore, this is a great time for tech providers, asset owners and consultants, as progress marches on!

Kris Embry is co-founder of Pressure Pipe Consulting Company.