Product Profile – The Next Generation of Manhole Assessment Technology

Research shows that in the United States alone, there are more 20 million manholes that provide access to a network of some 1.3 million miles of buried wastewater infrastructure. These manholes play a critical role in the overall utility network, as they provide access points to buried linear infrastructure.

Established in 1987, RedZone Robotics has a long history of robotic innovation. From Chernobyl to Nine Mile Point, and later, Ontario Hydro and Argonne National Laboratory, RedZone was established as a pioneer in the field of robotics and condition assessment. In 2017, RedZone Robotics was approached about utilizing robotics to perform inspections on a series of large vertical refractory chambers at one of the largest, integrated refinery and petrochemical facilities in the world.

In prior years, the “standard” method to inspect these large refractory chambers was to assemble scaffolding and use people and cameras to visually assess the interior walls. Not only did this take several days to assess a single asset, but it also put people in unsafe, confined space environments.

By leveraging decades of engineering design and robotic innovation, RedZone developed a pneumatically actuated robot, known as Mantis, with high-resolution cameras and lasers to inspect these challenging structures. Instead of taking multiple days, it only took 30 minutes to assess each chamber without the need for confined space entry. While this Mantis worked well for this specialty application, the platform was not scalable or easy to deploy for traditional manholes and vertical chambers — standard assets within wastewater collection systems. Recognizing the necessity to assess this abundance of critical infrastructure assets was a key factor in RedZone’s pivot to focus its attention on the needs of wastewater leaders.

Mantis, shown in a large diameter pipe.

Research shows that in the United States alone, there are more 20 million manholes that provide access to a network of some 1.3 million miles of buried wastewater infrastructure. These manholes play a critical role in the overall utility network, as they provide access points to buried linear infrastructure.

RELATED: Cities Save Money with System-Wide Approach to Asset Management

Having access to pipeline infrastructure is vital to ensure proper operation, maintenance, inspection, evaluation, renovation, and testing of these assets. The majority of these manholes have surpassed a service life of over 50 years with some dating back as far as the mid-19th century. Up to 90 percent of inflow and infiltration (I&I) can be attributed to manholes, significantly increasing maintenance and operations cost as additional flows are conveyed and treated.

Vertical inspection ensures that system owners effectively inspect all components of a collection system to determine structural integrity and operational and maintenance requirements in order to maximize the useful life of these critical assets.

Vertue can assess vertical assets up to 25 ft in diameter and over 150 ft deep.

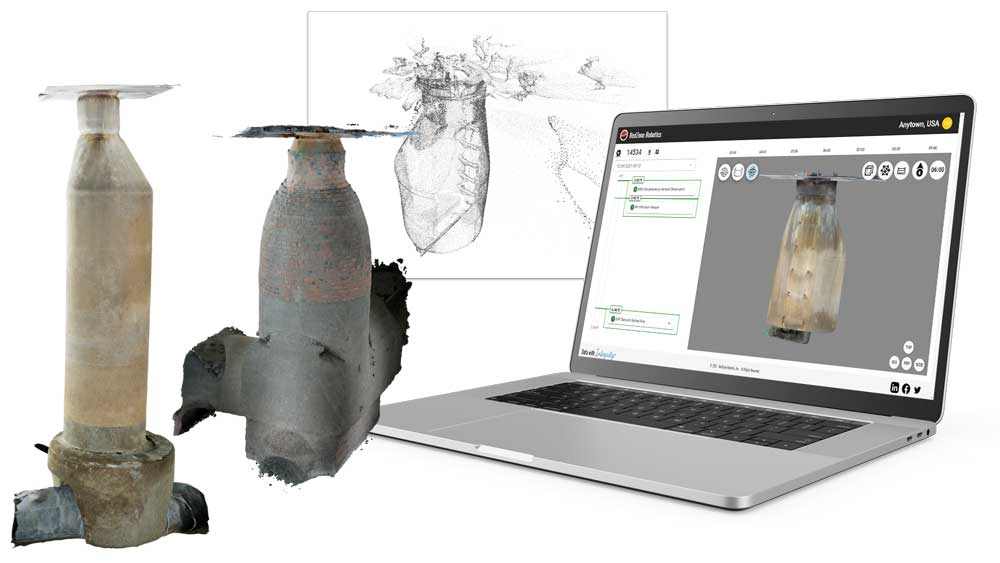

Recognizing the need to help wastewater leaders proactively address the health of the manholes in their collection system, RedZone launched Vertue in early 2021. A fully autonomous, multi-sensor, vertical asset inspection technology that includes multiple stereoscopic cameras, lasers, inertial measurement units (IMU’s) and a high-accuracy GPS receiver, Vertue is able to clearly and accurately assess vertical assets up to 25 ft in diameter and over 150 ft deep. With an emphasis on form, fit, and function, Vertue is compact and lightweight (13 lbs) and can be deployed anywhere with relative ease, but it is the combination of advanced sensor technologies that sets Vertue apart from the competition.

Integrity lets you see your assets with crystal clear imagery and 3D models and is accessible via internet browser.

Stereoscopic, or stereo, cameras simply mean that multiple camera lenses and imaging sensors are used in combination to simulate human binocular vision. The processing of these images leads to the generation of three-dimensional images or models, a process known as stereo photography. A profound benefit of stereo photography is the ability to accurately determine three-dimensional measurements from two-dimensional data, better known as photogrammetry.

RELATED: Robots and ROI – Return on Inspection Yields a $17M Savings on a Single Project

The ability to obtain, process, measure, and analyze real-world physical objects based on images is becoming a preferred assessment technology over other 3D data collection methods. By building high-accuracy models, with orientation and position information identified by the on board IMU’s and high-accuracy GPS, digital twins are at your fingertips.

Vertue provides crystal clear, 360-degree, flattened views of your vertical assets.

Coupled with Integrity, a cloud-based asset management SaaS, system owners get clear, complete data that allows them to better manage their system. Sensor data provides photogrammetric models, high-density point clouds, and asset measurement tools. With photogrammetry, it is possible to create detailed, three-dimensional models from a series of photographs using geometry and mathematics. With this technique, Vertue is able to produce these 3D models — digital twins — of system infrastructure that can be easily imported into asset management software for planning, saving utilities time and money. Standard output for Vertue is high-resolution 3D models, 360-degree videos, and NASSCO certified, MACP reports -all with the click of a button within Integrity, from any location, via internet browser.

Break free from the reactive repair cycle and use comprehensive inspection data to create a healthier, safer future for your system while protecting your wastewater infrastructure, and your community, from hazardous SSOs and system failures with Vertue and Integrity.