MaxLinerCLS Helps Cities Complete Lateral Rehabs

April 1, 2008

It’s a well-known fact that America’s wastewater infrastructure needs a lot more attention than its getting.

It’s a well-known fact that America’s wastewater infrastructure needs a lot more attention than its getting. The U.S. Environmental Protection Agency (EPA) estimates that the nation’s underground infrastructure has $200 billion in existing undocumented needs. Pipes in densely populated cities were built more than a century ago and are exhibiting significant signs of decay through leaks, voids and overflow issues. Cities across the United States are strapped with limited budgets and increasing pressure from consent decrees issued by the EPA. These consent decrees state that cities will receive a hefty fine for failing to rehabilitate their aging sewer pipes within a certain timeframe.

As a result, officials at public works departments face daily challenges prioritizing the growing number of rehabilitation projects. The silver lining in this cloud is a new trenchless technology product poised to help cities tackle sewer rehabilitation projects more effectively.

The new product is MaxLinerCLS, a complete lateral solution for sealing pipelines by starting from inside the mainline and continuing up the existing lateral for 10, 20, 30 or more continuous ft. In addition to sealing the lateral connection at the mainline — the weakest point for inflow-and-infiltration (I&I) in the line — this product provides a structural, one-piece cured-in-place pipe (CIPP) rehabilitation of the entire lateral. The result is an effective solution that decreases installation costs, doesn’t require a clean out and reduces project time, say officials with MaxLiner.

Because the weakest point in a sewer collection system is the lateral to the mainline connection, failures in this area quickly result in significant infiltration and sewage exfiltration problems. Roots can also quickly find a home via the cracks. Similar to other parts of the pipe, this area is even more prone to a complete collapse that could result in an emergency project. MaxLinerCLS addresses this area in a way no other products have in the past., company officials say.

“MaxLinerCLS saves both time and money because it provides a one-step, monolithic, leak-proof lateral rehabilitation solution that doesn’t require a clean out,” said Gil Carroll, MaxLiner director of business development.

How It Works

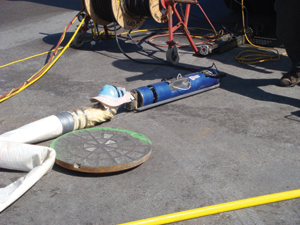

MaxLinerCLS provides continuous, extended-length lateral rehabilitation in one seamless step and effectively handles installations with 90 degree bends. With technology exclusively licensed to MaxLiner in North America by the National EnviroTech Group, MaxLinerCLS gives the joint area extra strength while unifying the lateral and mainline liners.

Enhancing the traditional MaxLiner system, which is an solution for conventional lateral rehabilitation, as well as for difficult access applications such as rooftop installation of vertical lines and difficult access installations from basements, MaxLinerCLS offers the added benefit of sealing the connection at the mainline. Additionally, with MaxLinerCLS, the lining process begins from inside the main and moves up to the lateral, minimizing the amount of digging and enabling the lateral to be relined without a clean-out.

“Without MaxLinerCLS, an installer conducting rehabilitation in an older area would have to dig access pits and shoot the liner down into the main, adding more time and money to the project,” Carroll said.

He added, “Cities also love the fact that this product seals the connection and protects the lateral liner during reinstatement of the service connection.”

How the Product Came to Be

MaxLiner, an industry leader in lateral pipe relining, first introduced MaxLinerCLS in February to visitors at the Pumper and Cleaner Show in Louisville, Ky. After years of working closely with the municipal market, MaxLiner saw the need for a product specifically to fit their needs.

While other monolithic solutions have been available to the municipal market for years, MaxLinerCLS was developed as an alternative to solutions, which typically extend only a short distance into the mainline from the lateral seal., Carroll said.

Like the MaxLiner system, MaxLinerCLS includes all the high-quality materials, supplemental products and hands-on training needed for successful installations. The system also employs 100 percent solid epoxy resins that will not shrink and do not contain styrene. MaxLinerCLS comes complete with a heated trailer, installation robot, materials and training.

Michele V. Brier is a freelance writer and owner of a marketing communications and public relations consulting business. She frequently writes about the trenchless technology industry.