Island Hopping on the Mississippi River

January 1, 2009

What does it take to bring power to a small island in the Mississippi River?

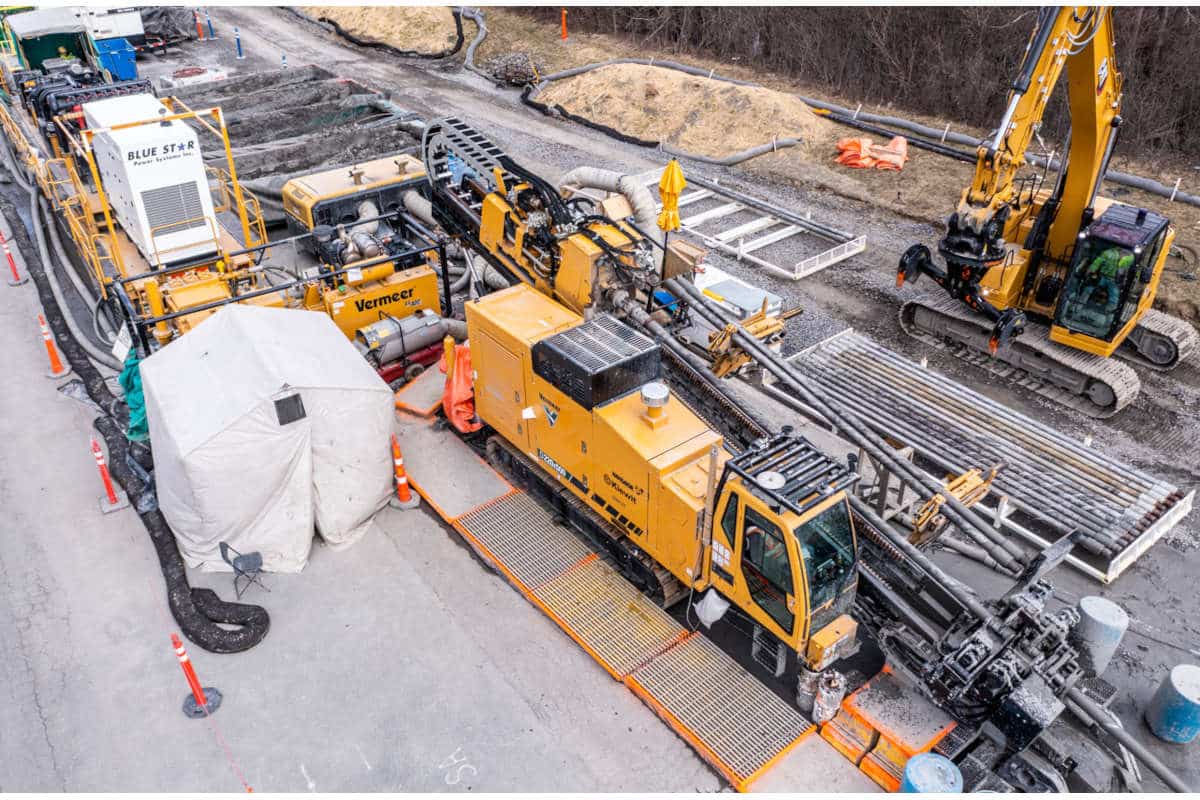

What does it take to bring power to a small island in the Mississippi River?Well, if you are Alliant Energy and you want the job done right, then you hire the right people. Alliant Energy did just that in spring 2008 when it awarded Michels Pipeline a project to install 5,300 ft of casing pipe capable of carrying a power cable from a boat landing in Prairie du Chien, Wis., to the north side of Indian Island located on the Mississippi River.

Indian Island is an isolated piece of land nestled between the Iowa and Wisconsin state lines and only accessible by boat. The aging power cables leading to the island were in dire need of repair. Because of the need, Alliant Energy stepped up to the plate and began looking for the resources required to fix the problem. Michels Pipeline subcontracted Michels Directional Crossings and Michels Power for the task and as One Michels, descended onto the area in early fall to make the much anticipated cable replacement happen.

Despite getting the job in the spring, Michels had a couple of good reasons to wait until beginning work in late September. “It turns out it was the best time to start work. Water levels were at an all-time low when the crews needed for the job were finally available,” says Michels Pipeline general manager Eric Grundman.

It may have been a good time for the crews but it was also a busy time for area duck hunters as work was in full swing during the height of duck hunting season. The mainland HDD entry point was located at a major boat landing that Michels shared with area duck hunters.

The job for Alliant Energy wasn’t without its challenges, which included: working around seasonal duck hunters, satisfying permitting agencies such as Department of Natural Resources, the U.S. Army Corps of Engineers and the U.S. Fish and Wildlife Service, and moving heavy equipment via barge to and from Indian Island.

Challenges

Late September is duck hunting season and the mainland project site for the crews from Michels was located at one of the busiest boat launches in the area. Hunters were everywhere. Workers decided to use the additional traffic as an opportunity and created a working partnership with the hunters. Excess materials such as shipping pallets used for fire wood were given to hunters, who in return, made sure to give the crews the space they needed to complete their work.

Wisconsin DNR inspectors were onsite to make sure drilling mud or other contaminants did not enter any of the surrounding water. “Our team was careful to make sure we walked the inspectors through the drilling process until they were comfortable and confident in Michels’ capabilities. The DNR was very pleased with the way we made sure the environment concerns were taken into consideration before we began any work,” says Michels’ operator Jessie Neu.

Wisconsin DNR inspectors were onsite to make sure drilling mud or other contaminants did not enter any of the surrounding water. “Our team was careful to make sure we walked the inspectors through the drilling process until they were comfortable and confident in Michels’ capabilities. The DNR was very pleased with the way we made sure the environment concerns were taken into consideration before we began any work,” says Michels’ operator Jessie Neu.Indian Island

Indian Island is not accessible by land so before any work could begin, crews needed to move tons of equipment to the Indian Island jobsite. Multiple times during the project, barges were used to move equipment such as a tractor/backhoe, excavator, v-groove cable puller, rope puller, air compressor, 1 mile of drill steel and assorted HDD tools to and from the island.

“We had to load our equipment onto the barge from St. Farrell Island, about a mile north of our actual jobsite. The main channel of the Mississippi River was used to make our way to the island because the weight was too much for the smaller channels,” says Neu.

Once the barges arrived at the island, they docked and unloaded the equipment about 1,000 yards south of the work site located at the northern end of the island. The equipment was unloaded and driven north on Arrowhead trail – a grassy area which at one time was an actual street on the island.

Casing Pipe Inside the Drill Stem

Michels has successfully completed all types of pipeline and HDD projects, but this job was going to be a different challenge. The smallest casing the drilling team wanted to install was 4 in., but room on the island was limited, making it difficult to put such a large amount of pipe together for the pull in. The use of smaller casing pipe was explored. The 3-in. steel pipe would slide through the drill stem instead of being pulled in when the drill steel was pulled out. A plan needed to be devised in how to get the casing into the bore pipe in order to complete the “push-in.”

“That’s really the strength of the One Michels concept at Michels Corp. — all the different capabilities of one company working together for our customer. It’s not typical for a directional drill to bore out a mile and pull back 3-in. pipe. The drillers came up with the idea to utilize a 3-in. steel pipe and slide it into the drill pipe. Michels Power suggested using a 10,000 lb V-Groove Cable Puller to assist with the push/pull-in,” says Grundman.

Michels’ HDD crew successfully bored to Indian Island, exiting at the exact planned location. The drill head or pilot head was removed upon reaching the island and 1 mile of clean drill rod, previously barged to the island, was attached and pulled one piece at a time back to the mainland.

The installation of the casing into the clean drill pipe took about six hours, start to finish. The Michels Pipeline crew had the 3-in. steel casing pipe welded in 1,000- to 1,100-ft sections.

“There was very little down time,” adds Grundman. “The crews stopped for about 30 minutes, four different times to allow the pipeline welders to connect the pre-welded sections during the casing installation.”

Push-Pull Installation

Before the Alliant HDD project could be called successful, the electric cable needed to be tested, installed and retested. The cable installation was achieved by utilizing an ARNCO Caterpillar track pushing machine on the mainland. While a mile away, on Indian Island, the cable was pulled through the casing using a rope pulling-reel trailer. A power reel on the mainland was also utilized to eliminate excess drag while the cable was being installed. Many gallons of cable lubricant helped to ease the cable through the casing. The very skilled Michels power crew operated all three machines in unison to maintain a steady pulling pressure. To avoid damage to the power cable, the crew could not exceed the maximum pulling tension on the cable.

Following a successful post installation test, crews from Alliant quickly put the new cable into service. With a joint effort from the Michels Pipeline and Power crews, site restoration was completed in several days, allowing for a final departure from the island just one day before fall rains began.

Following a successful post installation test, crews from Alliant quickly put the new cable into service. With a joint effort from the Michels Pipeline and Power crews, site restoration was completed in several days, allowing for a final departure from the island just one day before fall rains began.Safety Standards Remain

Despite the different and unique obstacles and challenges facing the crews on this job, according to the safety personnel, no incidents were reported. Both Alliant Energy and Michels Corp. worked together to make sure all precautions were taken to ensure a safe and efficient work environment.

The job for Alliant Energy was not a usual job for Michels Pipeline, Directional Crossings or Power. New concepts needed to be created because of the length and size of the pipe along with the watery elements. The drilling teams came up with ideas for the pipeline crews and vice versa, while all three crews worked together to make it happen for the customer.

Lisa Sanders is marketing communications specialist for Michels Corp., Brownsville, Wis.