Is FOG Getting Too Much Blame for Sewer Blockages?

We have all heard the claim that fats, oils, and grease (FOG) are a leading cause of sewer blockages and sanitary sewer overflows (SSOs). Some areas of the country report that as much as 70 percent of their blockages are caused by FOG. This is leading U.S. cities and sewering agencies to adopt strict FOG control ordinances and investing more and more resources into restaurant inspections, education and outreach, and sewer line maintenance.

We have all heard the claim that fats, oils, and grease (FOG) are a leading cause of sewer blockages and sanitary sewer overflows (SSOs). Some areas of the country report that as much as 70 percent of their blockages are caused by FOG. This is leading U.S. cities and sewering agencies to adopt strict FOG control ordinances and investing more and more resources into restaurant inspections, education and outreach, and sewer line maintenance.

But how much of the blockage problem is really attributable to FOG? When a FOG-related blockage area (i.e., hot spot) is identified, are there unidentified factors that are contributing to the problem? Are those unidentified contributing factors often a bigger problem than the FOG? How would a sewering agency’s FOG control approach be modified if they had the answers to these questions?

Comprehensive FOG Characterization has many elements, but the focus of this article is the characterization activities involving closed-circuit television (CCTV) inspections of FOG-related hot spots to identify the “true” cause(s) of a blockage or problematic FOG accumulation.

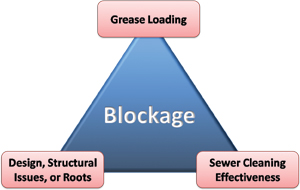

Many sewering agencies already have libraries full of CCTV inspection data focusing primarily on pipeline defects, but have neglected to thoroughly characterize their FOG hot spots. They have not asked the question: Why is FOG accumulating in this location but not further upstream or downstream? Therefore, Environmental Engineering & Contracting (EEC), Santa Ana, Calif., developed a method of CCTV inspecting FOG hot spots in order to objectively determine the true causes of the blockage. EEC developed the FOG Blockage Triangle to illustrate how causes of the hot spot are characterized:

Many sewering agencies already have libraries full of CCTV inspection data focusing primarily on pipeline defects, but have neglected to thoroughly characterize their FOG hot spots. They have not asked the question: Why is FOG accumulating in this location but not further upstream or downstream? Therefore, Environmental Engineering & Contracting (EEC), Santa Ana, Calif., developed a method of CCTV inspecting FOG hot spots in order to objectively determine the true causes of the blockage. EEC developed the FOG Blockage Triangle to illustrate how causes of the hot spot are characterized:

Simply put, proper characterization should tell you if the true cause of a FOG hot spot is solely due to FOG loading (i.e., the FOG discharge from restaurants and residences) or whether structural issues/roots or cleaning ineffectiveness are contributing significantly to the problem.

Why is this important? Let’s examine three FOG hot spot scenarios characterized using CCTV inspection methods developed by EEC:

For hot spot No.1, FOG loading is determined to be the sole cause of the hot spot. In this case, increased FOG source control measures such as grease interceptors, restaurant inspections and education and outreach are the logical solution to the problem.

However, for hot spot No. 2, a previously unidentified structural issue (e.g., a severe sag) or a root problem is identified as causing the FOG to accumulate in the pipe. In this case, the strategy for solving this hot spot is entirely different and increased FOG source control may help the situation, but will not solve it. Note: Throughout FOG characterization studies, the impact of severe sags on FOG accumulation is the factor most commonly overlooked. In some cases, repairing the sag is the most cost-effective, long-term solution. In others cases, the awareness of the presence of the sag leads to a change in line cleaning methods or frequency which may be the more cost-effective solution.

However, for hot spot No. 2, a previously unidentified structural issue (e.g., a severe sag) or a root problem is identified as causing the FOG to accumulate in the pipe. In this case, the strategy for solving this hot spot is entirely different and increased FOG source control may help the situation, but will not solve it. Note: Throughout FOG characterization studies, the impact of severe sags on FOG accumulation is the factor most commonly overlooked. In some cases, repairing the sag is the most cost-effective, long-term solution. In others cases, the awareness of the presence of the sag leads to a change in line cleaning methods or frequency which may be the more cost-effective solution.

For hot spot No. 3, if the method used to clean the hot spot piping is shown to be only marginally effective (e.g., leaving much of the old FOG behind), then the strategy for solving this hot spot is completely different again. Perhaps a new cleaning method would solve 90 percent of this problem. Ineffective cleaning causes two problems. First, failing to remove all of the FOG from the pipe obviously reduces the opening in the pipe. Additionally, FOG tends to accumulate on itself, so any FOG left behind after cleaning will cause new FOG to accumulate faster. Note: In FOG characterization studies, the most common recommendation is for improvements in FOG hot spot cleaning methods.

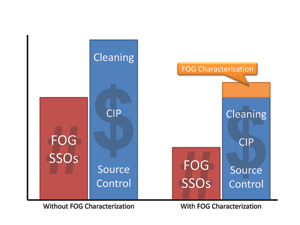

Now that we have examined three different hot spots, we see that there were three completely different solutions to the FOG blockage problem. In these FOG characterization studies, even though reducing FOG loading is always a factor, it is not uncommon for repairs of structural issues and improved line cleaning methods to be the primary recommendations. This is particularly true when the FOG hot spot is in a residential area where reducing the FOG loading by increasing source control efforts will be difficult. When studying FOG, the traditional focus has always been on FOG source control. Therefore, our clients are typically surprised by our recommendations and are often expecting us to recommend more grease interceptors, more restaurant inspections and more education and outreach. Although this is the proper recommendation for some hot spot areas, most of our recommendations focus on those issues that sewering agencies thought they already had identified: structural, roots and cleaning.

In the end, proper FOG Characterization will lead to surprising findings and unique information sharing between the engineering, maintenance and source control departments of a sewering agency. Technically-based programs, procedures and regulations will be developed, ultimately resulting in reductions in SSOs and long-term costs.

John Shaffer is a wastewater chemist and president of Environmental Engineering & Contracting Inc (EEC) in Santa Ana, Calif. He is the author of multiple FOG control studies and speaks throughout the country on issues related to FOG, Pretreatment and SSO Management.