Drill Master: Lost Circulation Material LCM

Loss of returns, flow or circulation can be a problem in HDD installations. Zones of high porosity/permeability, natural fractures, rubble zones, gravel and natural voids can all cause loss of drilling fluid to the formation.

In these cases, bentonite and standard fluid additives may not be sufficient to seal the borehole. Some sort of coarser bridging agent may be required. Lost circulation material (LCM) may be necessary.

LCM is found in three forms: fiber, flake and granular. The fiber types of LCM are usually made from shredded paper, cane fiber, wood fiber or spun mineral fiber. The flake types of LCM are usually made from mica, ground Formica or cellophane. The granular materials are made from ground nut hulls, granular bentonite or water swellable, non-soluble, crystalline polymers. Additionally, each type of material can come in different sizes: fine, medium and coarse.

The choice of LCM to use can depend on several factors, including the type of loss. In seepage situations in sand, fine flake or fiber material may be of benefit. In fractures in rock, coarser material may be needed to plug and seal the fracture. If natural voids are encountered, water swellable crystalline polymers or granular bentonite may help fill and seal the void. Combinations of these materials can also be beneficial. Blends of all three types of LCM are available in fine, medium and coarse. The blends take much of the guesswork out of choosing a certain type and the only decision to make is the required size.

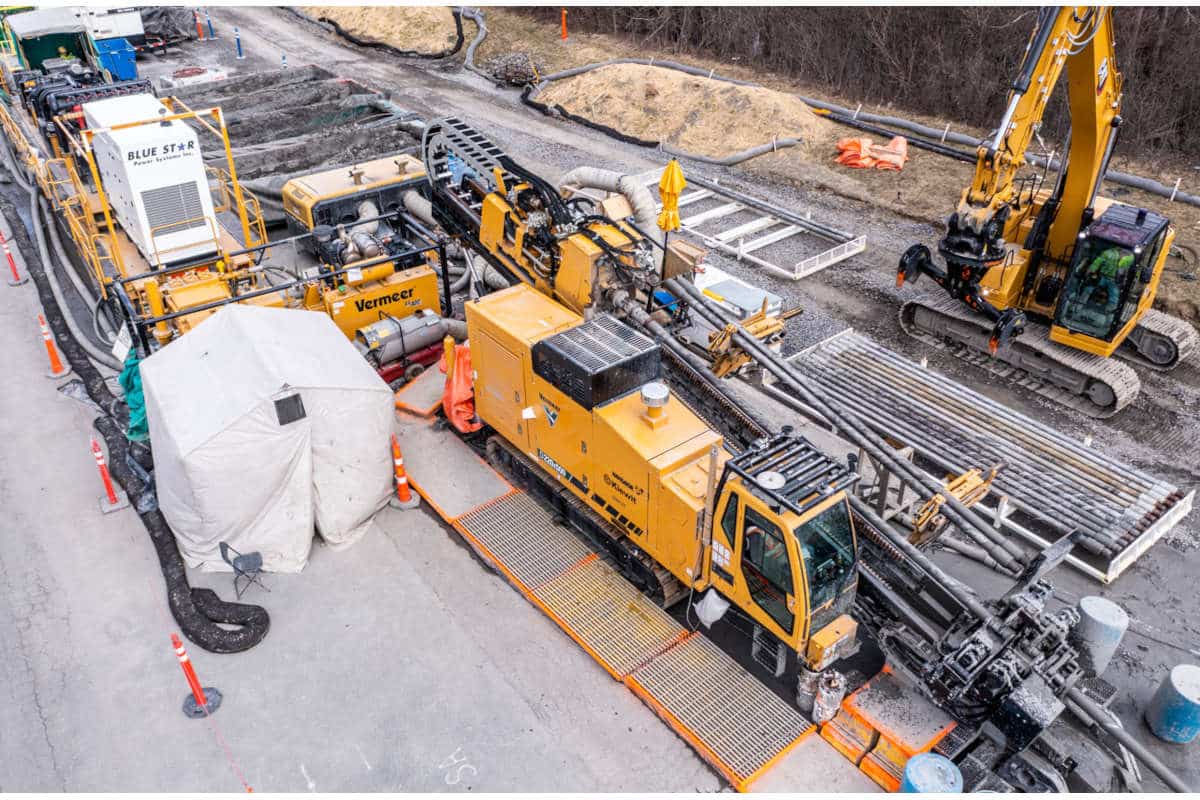

The rig pump can also be a factor in choosing the LCM to use. Large river crossing rigs, having larger pumps, will normally be able to pump a much larger variety of LCM than the smaller utility rigs. Smaller utility rigs with smaller pumps may be limited to the finer size LCM. Regardless of pump size, all screens in the fluid system must be removed before using LCM. A properly working LCM will plug any screens left in the fluid system. Larger nozzles in the bit and reamer may also be necessary.

Availability can be a limiting factor in LCM choice. These materials may be readily available in active oilfield areas but most HDD work is performed outside these areas. If losses are anticipated because of geotechnical information, local knowledge or any other reason, a supply of LCM should either be on the job site or located in advance as a contingency plan.

A research project was performed at the University of Alberta in Edmonton, Alberta, in a commercial gravel pit with three 200-ft installations of 4-in. SDR 17 high density polyethylene (HDPE) made at depths of 5 ft. The first installation required 3,500 total gal of fluid during the pilot bore and pullback. The fluid used consisted of soda ash, bentonite (50 lbs per 100 gal water) and a suspension enhancer. Good slurried flow was maintained for 110 ft. On the first pilot bore, flow was lost at 110 ft and inadvertent returns occurred. Inadvertent returns continued through the rest of the pilot bore and throughout the reaming process.

The second installation used the same fluid with the addition of a fibrous suspension agent at a concentration of 0.5 lbs per 100 gal of fluid. Flow was maintained for 150 ft at which time returns were lost and inadvertent returns occurred. Inadvertent returns continued through the rest of the pilot bore and throughout the reaming process. A total of 3,000 gal of fluid was used.

The third installation used the same fluid as the second but a fine, fibrous LCM (N-Seal) was added at a concentration of 4 lbs per 100 gal of fluid. A total of 2,200 gal of fluid was used and flow was maintained on both the pilot bore and during the reaming process. A higher concentration of the LCM would probably have reduced the fluid usage even more.

LCM can be a valuable, cost-effective tool in reducing fluid losses and preventing inadvertent returns.