Chemical Grouting & Manholes

April 1, 2009

There are many options for repairing leaks in concrete structures. One of the oldest, yet least understood repair methods utilizes polyurethane chemical grouts that react with water to either bond with the concrete to form watertight, permanent seals or to become rigid, filling voids and stabilizing soil.Recent studies and more than 40 years of experience indicate that America’s first trenchless technology is still the best, most cost-effective, long-term defense against infiltration of groundwater into structurally sound sewer systems.

Infiltration occurs when defects in below-grade structures like sanitary sewer lines, manholes, pump stations, catch basins or storm drains allow groundwater to enter the system. This infiltration adds to treatment costs and increases the risk of sanitary sewer overflows (SSOs).

Groundwater leaks also carry sand, silt and other debris into the system, increasing wear and tear on equipment. Voids are often created around these structures and can lead to an unstable foundation and settlement.

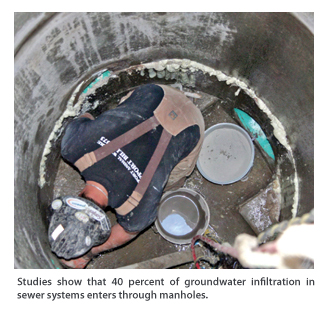

Studies show that 40 percent of groundwater infiltration in sewer systems enters through manholes. Utilizing chemical grouting, leaks can be stopped in a matter of minutes, permanently and with immediate cost-savings. Chemical grouting is always the right solution for repairing leaks caused by non-structural defects in manholes. Some candidates for chemical grouting include brick manholes, cast-in-place manholes, pipe penetrations and pre-cast manholes.

Before installing structural rehabilitation systems, it is important to eliminate all active infiltration. Manholes that require structural rehabilitation usually involve a spray, hand-applied or cured-in-place (CIP) lining system. Too often existing leaks in manholes are treated by applying a quick-set hydraulic cement over the active infiltration, which stops the leak temporarily, giving the lining system time to be installed. This temporary patch allows water to remain within the primary structure and can lead to a weakened bond or the future failure of the lining system.

The Basics of Installation

The Basics of Installation

Polyurethane chemical grouts are usually injected under pressure as a liquid resin into or in the vicinity of the leak. Once the resin contacts water, a chemical reaction occurs. Depending on the material formulation, the grout/water combination forms either a closed-cell foam or a non-cellular gel. The foam created can be flexible and resilient (hydrophilic) or rigid, meaning the cell structure of the foam crushes when compressed (hydrophobic).

In most manhole leak scenarios, the water flow or leak can be utilized to pull the grout into the structure. To accomplish this, a hole is drilled in the vicinity of the leak and the chemical grout is injected through the wall into the water source. As the resin reacts with the groundwater, it is pulled back into the structure and seals the leak from the outside in, thus creating a seal through the entire wall. Chemical grouts can also be injected directly into the defect in cases where the leak is not strong enough to pull the chemical grout into the structure. The expansion of the foam helps drive the grout through the structure to seal the defect.

Hydrophilic polyurethane resins that produce gels are typically installed by injecting water along with the resin through a manifold that briefly mixes the two prior to being injected. These gels are non-expansive but can be produced at water-to-resin ratios as high as 15 parts water to one part resin.

Choosing the Correct Product

Both hydrophilic and hydrophobic chemical grouts will seal leaks in all types of concrete structures initially. The issue is how to create a permanent seal. As with any type of repair, choosing the right repair material has a great impact on the longevity of the repair. There is no single product on the market today that is a fix-all, do-all for repairing all leaks in concrete. With correct installation techniques and proper material selection, most chemical grouting repairs are permanent.

To break down the decision process, the basic properties of both hydrophobic and hydrophilic chemical grouts must be taken into consideration. The properties of each type can be utilized to reduce the cost of installation and improve the quality of the repair long term.

Hydrophilic: Latin Hydro = Water and Philic = Affinity

Hydrophilic chemical grouts can produce either closed cell foam or a non-cellular gel when mixed with water. When activated, foams expand in volume between five to eight times. The volume of gel produced is relative to the ratio of water mixed with resin during installation. Hydrophilic gels can shrink after cure in the absence of water. Hydrophilic chemical grouts bond to wet surfaces tenaciously due to their water-scavenging agents. Hydrophilic chemical grouts are flexible and resilient after full cure and will allow movement to occur in the structure without damaging the seal or bond.

Hydrophobic: Latin Hydro = Water and Phobic = Fear

Hydrophobic chemical grouts require a catalyst that is blended into the resin prior to installation. The dosage of catalyst added to the resin controls the reaction time and the volume of foam produced. Hydrophobic resins have an aggressive expansion that can be as much as 29 times in volume. Hydrophobic chemical grouts repel water after activation. Hydrophobic resins cure rigid and do not recover well from compression. If the structure moves, there is good chance the cell structure will be damaged and leaks will reappear. Hydrophobic chemical grout is low in viscosity and permeates loose and non-consolidated soils readily.

Knowing the basic differences in hydrophobic and hydrophilic chemical grouts is a crucial step in making the correct choice of repair material.

Helpful Tips: What to Do

- If a leak repair project involves a non-structural defect in a concrete or masonry structure, a hydrophilic chemical grout should be used to seal the leak unless job conditions dictate otherwise.

- Gels should be used only in below grade structures where either moisture from the interior (like in a manhole) or from groundwater present to keep the cured gel hydrated. Gels will shrink if water becomes absent, but provide a low-cost alternative to foams.

- Foams are appropriate for above-grade or below-grade installation. They are typically 85 percent air-filled after cure and have excellent elongation, compression and rebound for use in expansion joints, cracks or any other non-structural defect in concrete structures.

- Utilize the aggressive expansion of hydrophobic chemical grouts if repairing a gushing leak that is impractical to repair with milder expanding hydrophilic resins. In below-grade structures, this is a good way to fill voids that may be present outside the structure. Once the leak is reduced to a manageable level, hydrophilic resin should be injected into the defect to back up the hydrophobic material.

- Inject hydrophilic gel into gushing leaks neat or with a 1:1 water-to-resin mix ratio to shut down gushing leaks. This is a case where you push as much material in as possible as fast as you can. If a high-volume pump is available, less material will be used to stop the leak due to reduced dilution of the resin in the water source.

- Use “Activated Oakum” (dry oakum soaked in hydrophilic resin) to reduce the flow in gushing leaks. If the leak can be slowed, a hydrophilic resin may be used to complete the repair. This technique is very suitable for sealing around pipe penetrations and plugging holes from the manufacturing of pre-cast structures.

What to Avoid

- Avoid installing gels in expansion joints or cracks that are subject to movement. Gels form a solid material with little or no cellular structure to disperse tension under compression. This tension can split the gel and damage the seal.

- Avoid installing hydrophobic chemical grouts for repairing minor leaks in cracks or joints. The repair will be temporary.

- Don’t get in a hurry when repairing tight cracks and minor leaks. These can be the most difficult to repair long term.

Conclusion

As our infrastructure ages, chemical grouting will continue to maintain its value as one of the easiest, most cost-effective and longest-lasting repair solutions available. If the right chemical grout is chosen for your repair project and the correct installation techniques are used, the repair will actually outlast the structure.

Scott Kelly has been a technical support specialist with Prime Resins Inc., Conyers, Ga., for more than 16 years.

The Basics of Installation

The Basics of Installation